6

CONTENTS

1SAFETY............................................................................................................................8

1.1 Safety Rules.................................................................................................................8

1.2 Danger Zones on the Machine.....................................................................................9

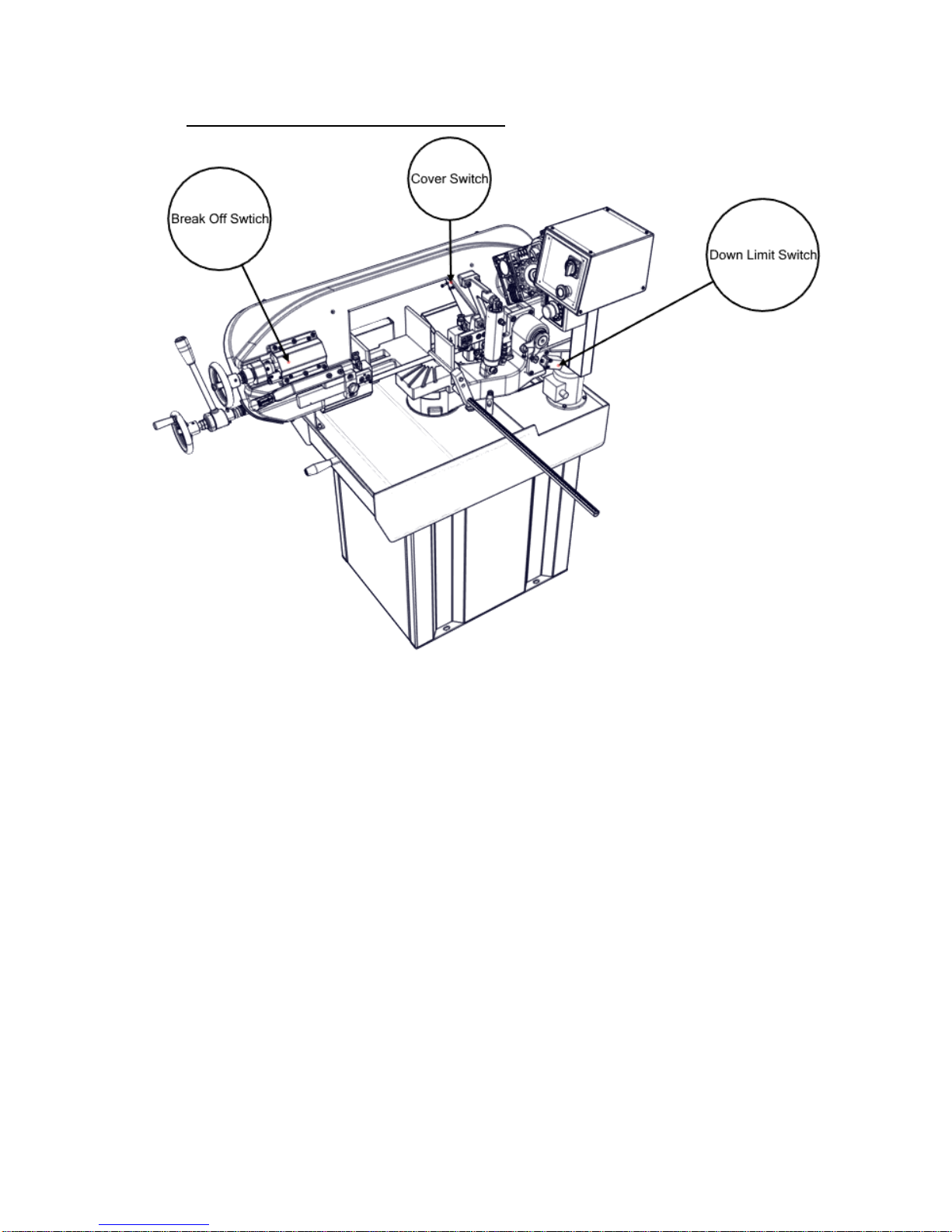

1.3 Safety Equipments On The Machine.........................................................................10

1.3.1 Break-off Switch ................................................................................................11

1.3.2 Cover Switch......................................................................................................11

1.3.3 Down Limit Switch............................................................................................11

1.3.4 Emergency Stop Button .....................................................................................11

1.4 Warning Labels and Assignments.............................................................................12

1.4.1 Glove Label........................................................................................................12

1.4.2 Electricity Neutral Warning Label .....................................................................12

1.4.3 High Voltage Label............................................................................................12

1.4.4 Safety Equipments Label ...................................................................................12

1.4.5 Arrow Label .......................................................................................................12

2DESCRIPTION AND PROPERTIES..........................................................................13

2.1 Technical Specifications of the Machine...................................................................13

2.2 Standard Equipment ..................................................................................................13

2.3 Noise Level................................................................................................................13

2.4 Machine Dimensions.................................................................................................14

2.5 Properties Table According to Forms of Swarf.........................................................15

2.6 KMT 180 CRAFT Bandsaw Machine Cutting Capacity...........................................15

3TRANSPORTATION AND INSTALLATION...........................................................16

3.1 Handling the Unpacked Machine..............................................................................16

3.2 After Unpacking the Machine ...................................................................................16

3.3 Environmental Conditions.........................................................................................16

3.4 Machine Placement and Position...............................................................................16

4PREPARATION BEFORE OPERATION..................................................................17

4.1 Cleaning.....................................................................................................................17

4.2 Lubricating.................................................................................................................17

4.3 Coolant.......................................................................................................................17

4.4 Electrical Power Connection.....................................................................................17

4.5 Final Inspection Checklist before Operation.............................................................17

5OPERATION..................................................................................................................18

5.1 Control Panel.............................................................................................................18

5.2 Blade Changing Procedure........................................................................................20