Contents

MACHINE CERTIFICATION AND IDENTIFICATION MARKING.............................. 2

ATTENTION!!!.................................................................................................................... 2

EC DECLARATION OF CONFORMITY .......................................................................... 3

WARRANTY CONDITIONS.............................................................................................. 4

WARRANTY REGISTRATION FORM............................................................................. 5

CHAPTER I : SAFETY................................................................................................ 7

1. Safety Rules .................................................................................................................. 7

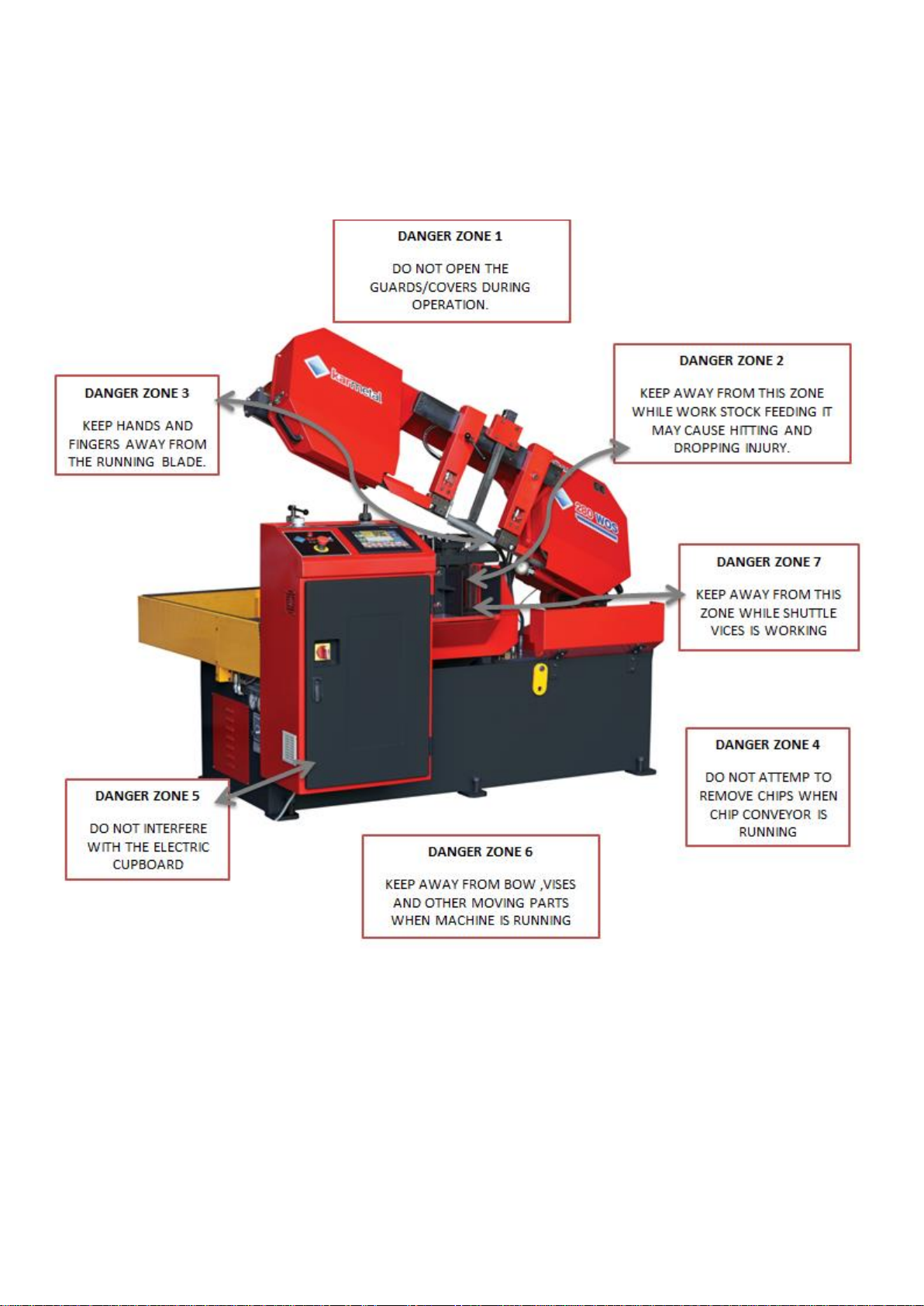

2. Danger Zones on the Machine...................................................................................... 8

3. Safety Equipments and Assignments............................................................................ 9

4. Warning Labels and Assignments .............................................................................. 12

CHAPTER II : DESCRIPTION AND PROPERTIES ............................................... 13

1. Technical Properties of the Machine .......................................................................... 13

2. Standard Equipment.................................................................................................... 13

3. Optional Equipment.................................................................................................... 13

4. Noise Level................................................................................................................. 13

5. Machine Dimensions .................................................................................................. 14

6. Properties Table According to Metal Sawdust ........................................................... 15

7. KMT 280 WOS Bandsaw Machine Cutting Capacity................................................ 15

CHAPTER III : TRANSPORTATION AND INSTALLATION.................................. 16

1. Handling the Unpacked Machine................................................................................. 16

2. After Unpacking the Machine ..................................................................................... 16

3. Environmental Conditions.......................................................................................... 16

4. Shipping Brace............................................................................................................ 17

5. Machine Placement and Position................................................................................ 17

CHAPTER IV : PREPARATION BEFORE OPERATION ...................................... 18

1-Cleaning....................................................................................................................... 18

2- Removing the Shipping Brace .................................................................................... 18

3- Lubricating.................................................................................................................. 18

4- Hydraulic .................................................................................................................... 18

5- Coolant........................................................................................................................ 18

CHAPTER V: OPERATION.......................................................................................... 20

1- Control Panel.............................................................................................................. 20

2- Touch Panel................................................................................................................ 21

3- Machine Function/System Description ...................................................................... 31

CHAPTER VI: MAINTENANCE.................................................................................... 35

2- WEEKLY MAINTENANCE..................................................................................... 35

3- MONTHLY MAINTENANCE.................................................................................. 35

4- SIX-MONTHLY MAINTENANCE.................................................................... 35

5- PERIODIC MAINTENANCE .................................................................................. 35

CHAPTER VII: TROUBLESHOOTING......................................................................... 36

CHAPTER VIII: DISMANTLING................................................................................... 37

CHAPTER IX. SPARE PART LIST.................................................................................. 38

9.1. MACHINE BASE ASSEMBLY ............................................................................. 40

9.2. JOINT ASSEMBLY................................................................................................ 42

9.3. BOW ASSEMBLY.................................................................................................. 44

9.3.1 BRUSH COMPLETE............................................................................................ 46

9.4. BOW LIFT CYLINDER.......................................................................................... 48

9.5 GEARBOX ASSEMBLY......................................................................................... 52

9.6. BLADE TENSIONING ASSEMBLY..................................................................... 54

9.7. CLAMP ASSEMBLY ............................................................................................. 56

9.8. BLADE GUIDE ASSEMBLY ................................................................................ 71

9.9. ELECTRIC GROUP................................................................................................ 77