66

9046.

A 4 Maintenance

■

Repair and maintenance work on the

electrical part of the unit may be performed

only by qualified specialists or trained per-

sons who have been made aware of the

safety regulations. For maintenance work,

disconnect the mains plug or isolate the

unit completely from the mains supply,

thus cutting off power to the unit.

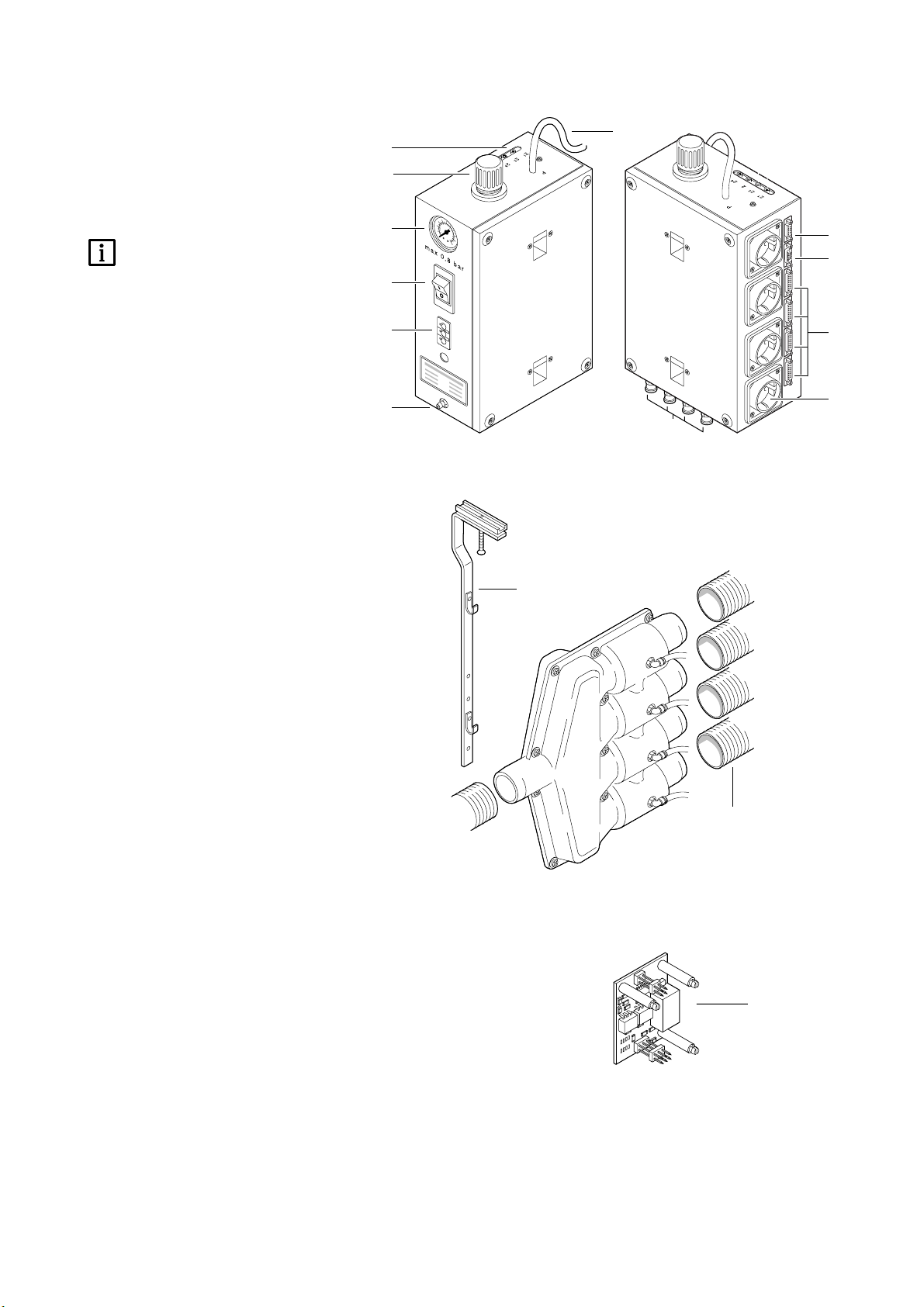

The supplementary control and the suction

path diverter require no special mainte-

nance.

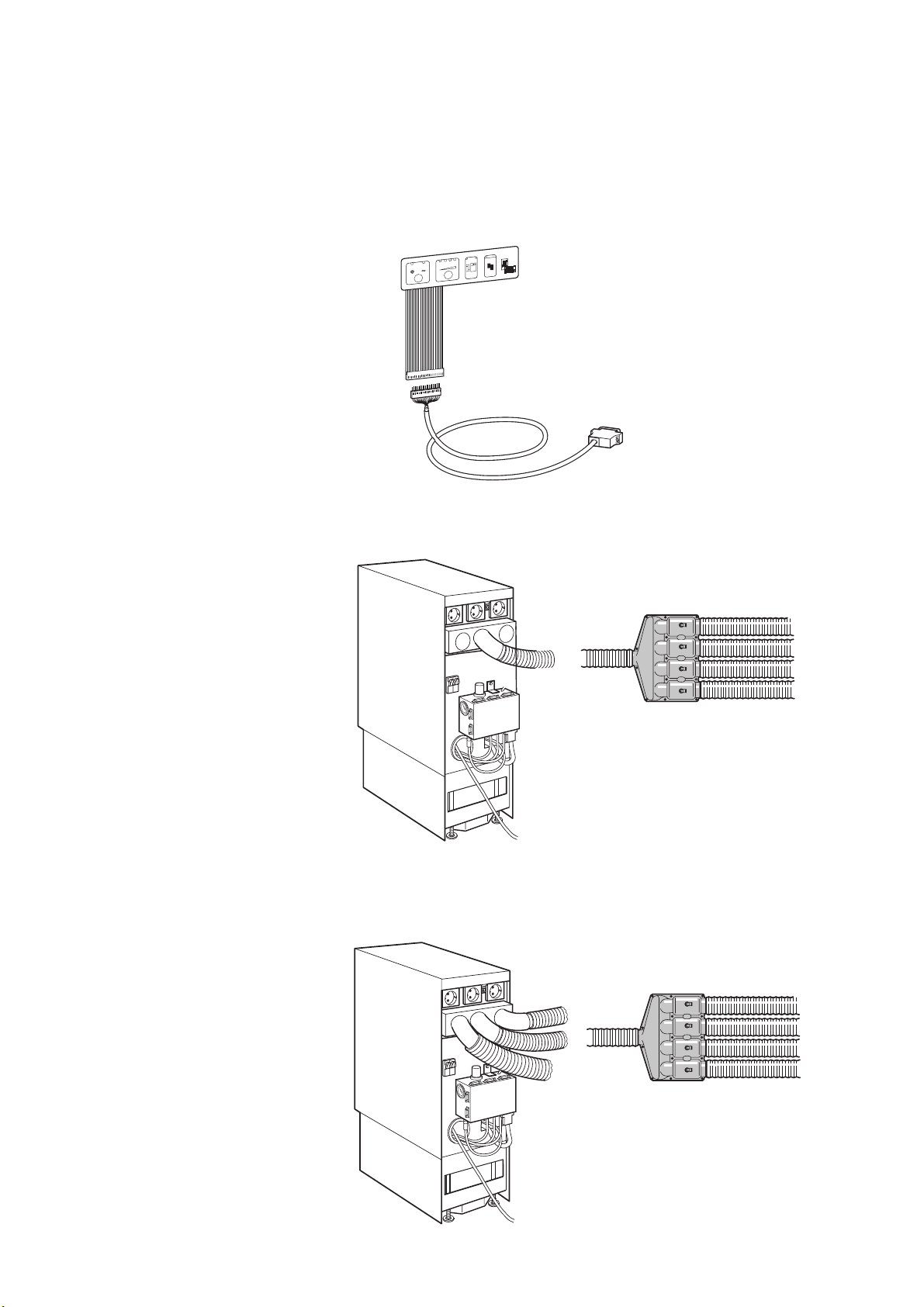

At regular intervals, check the connections

of the suction hoses and compressed air

lines for leaks.

A 5 Malfunctions

Repair and maintenance work on the

electrical part of the unit may be

performed only by specialists or persons

who have been trained in the factory and

have been made aware of the safety

regulations. Before opening housing parts,

disconnect the mains plug or isolate the

unit completely from the mains supply,

thus cutting off power to the unit.

Error messages of the supplementary

control are indicated by flashing of

the red error LED @ on the external sealed

keypad. The number of flashes corresponds

to the error number.

C• Component error

R• Contact Customer Service.

C • The CAN main control in the ABSOR-

matic plus and the CAN supplementary

control check for each other’s presence.

This error is output if one of the two con-

trols does not respond (switched off, pro-

gram error, etc. .

R • Check whether supplementary control

has been properly connected to the power

supply. Then restart main control at the

mains switch or by RESET.

E= Error C= Cause R= Rectification

F 03 • CAN-Nodeguarding fault

F 01 • Component error