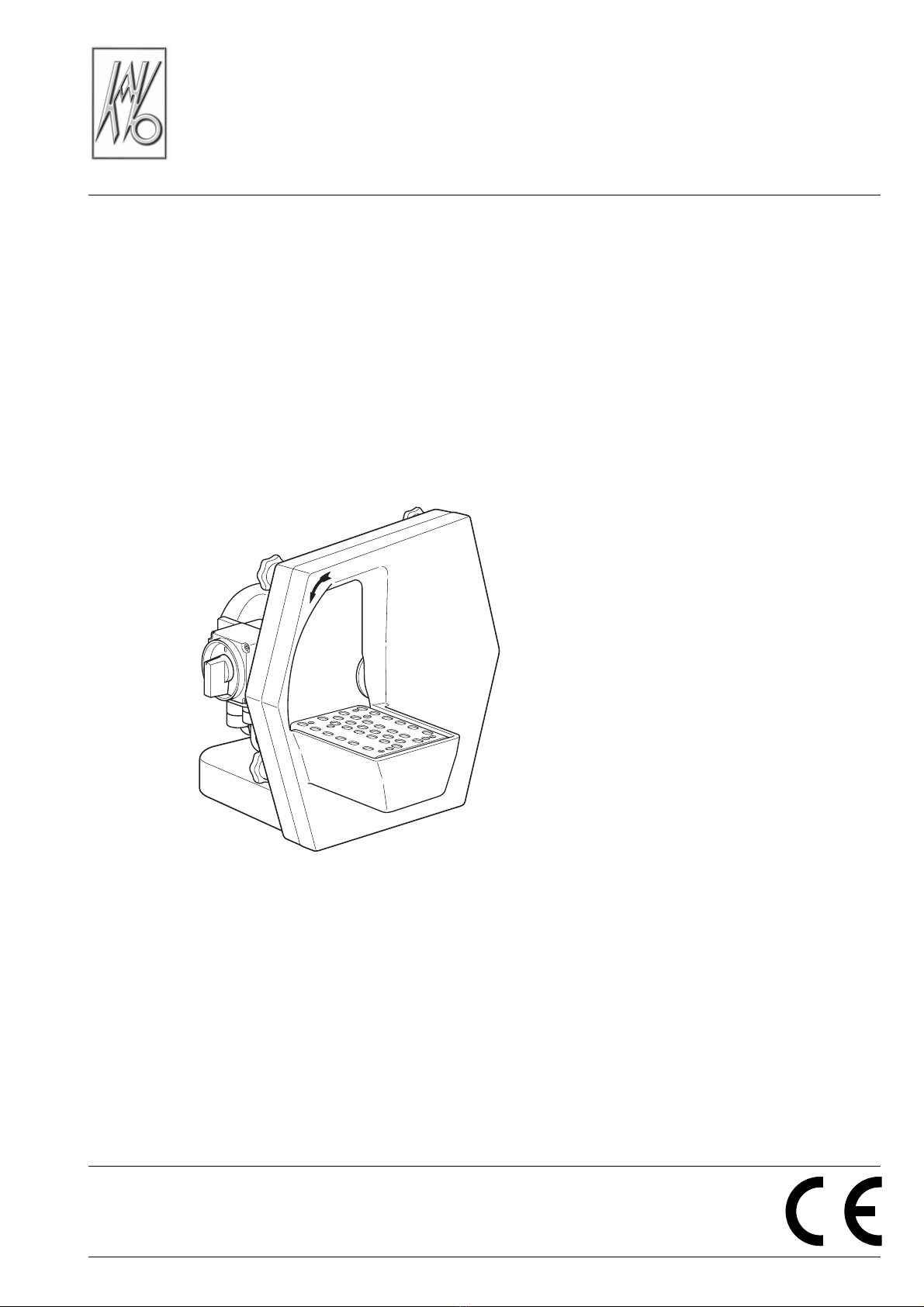

EWL 5831 1

GB

TABLE OF CONTENTS

A 1 For your safety ............................................................................................................................................2

A 1.1 Proper use of the product ....................................................................................................................2

A.1.2 Explanation of the safety symbols in these instructions ......................................................................2

A 1.3 Safety considerations ..........................................................................................................................2

A 1.4 Sources of danger ................................................................................................................................2

A 1.5 Observance of the Operating Instructions ............................................................................................2

A 1.6 Liability for function and damage ........................................................................................................3

A 1.7 Authorized Users ..................................................................................................................................3

A 2 Maintenance and Cleaning ........................................................................................................................4

A 2.1 Maintenance ........................................................................................................................................4

A 2.2 Cleaning ..............................................................................................................................................4

A 3 Applications ................................................................................................................................................4

A 4 Preparing for installation ............................................................................................................................4

A 4.1 Unpacking/Transport ............................................................................................................................4

A 4.2 Included accessories ............................................................................................................................4

A 4.3 Setting up and location ........................................................................................................................4

A 5 Handling ........................................................................................................................................................5

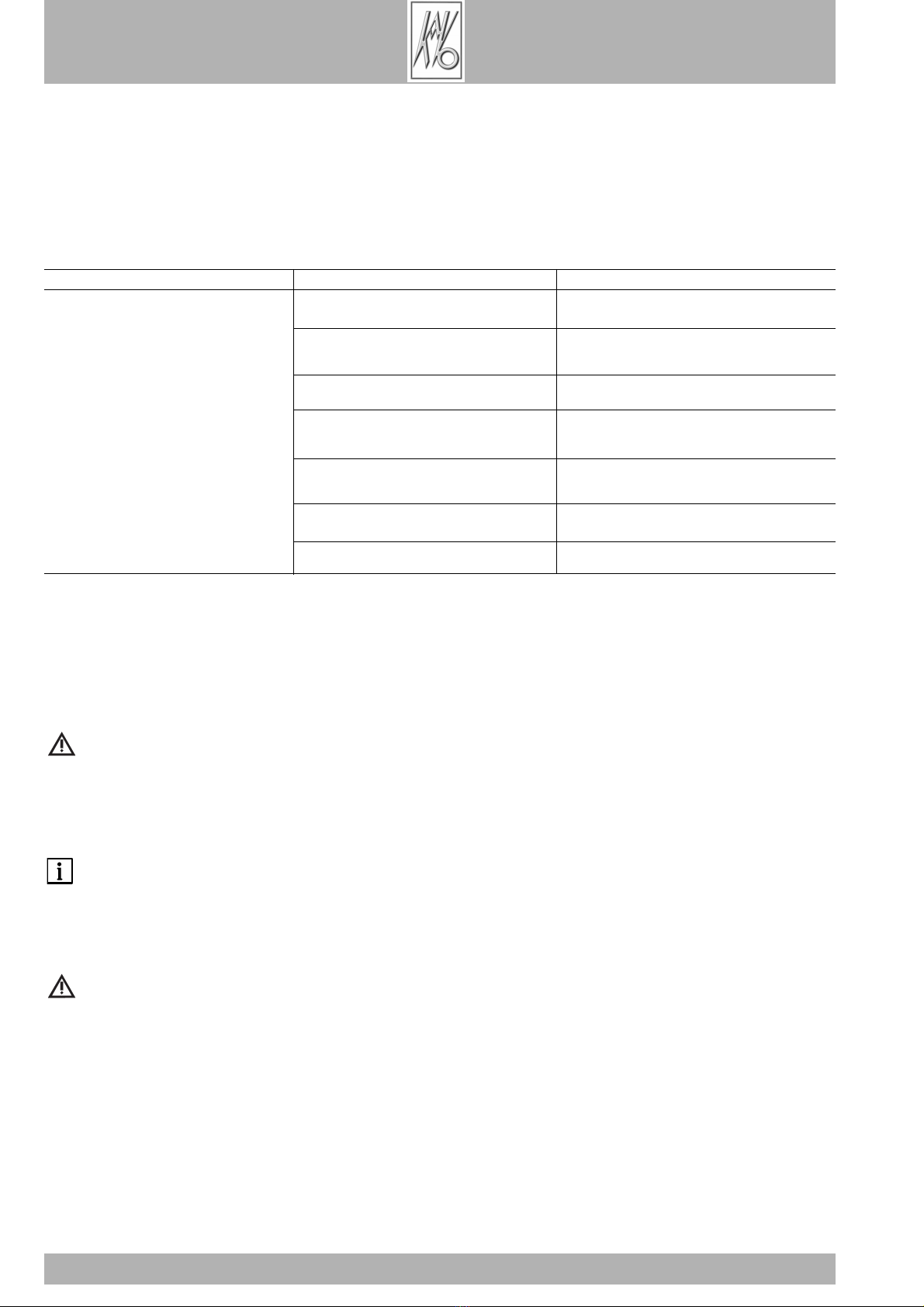

A 5.1 Technical data ......................................................................................................................................5

A 5.2 Water control ........................................................................................................................................5

A 6 Installation ....................................................................................................................................................6

A 6.1 Location ................................................................................................................................................6

A 6.2 Water connection ..................................................................................................................................6

A 6.3 Drainage hose ......................................................................................................................................6

A 7 Fittings ..........................................................................................................................................................7

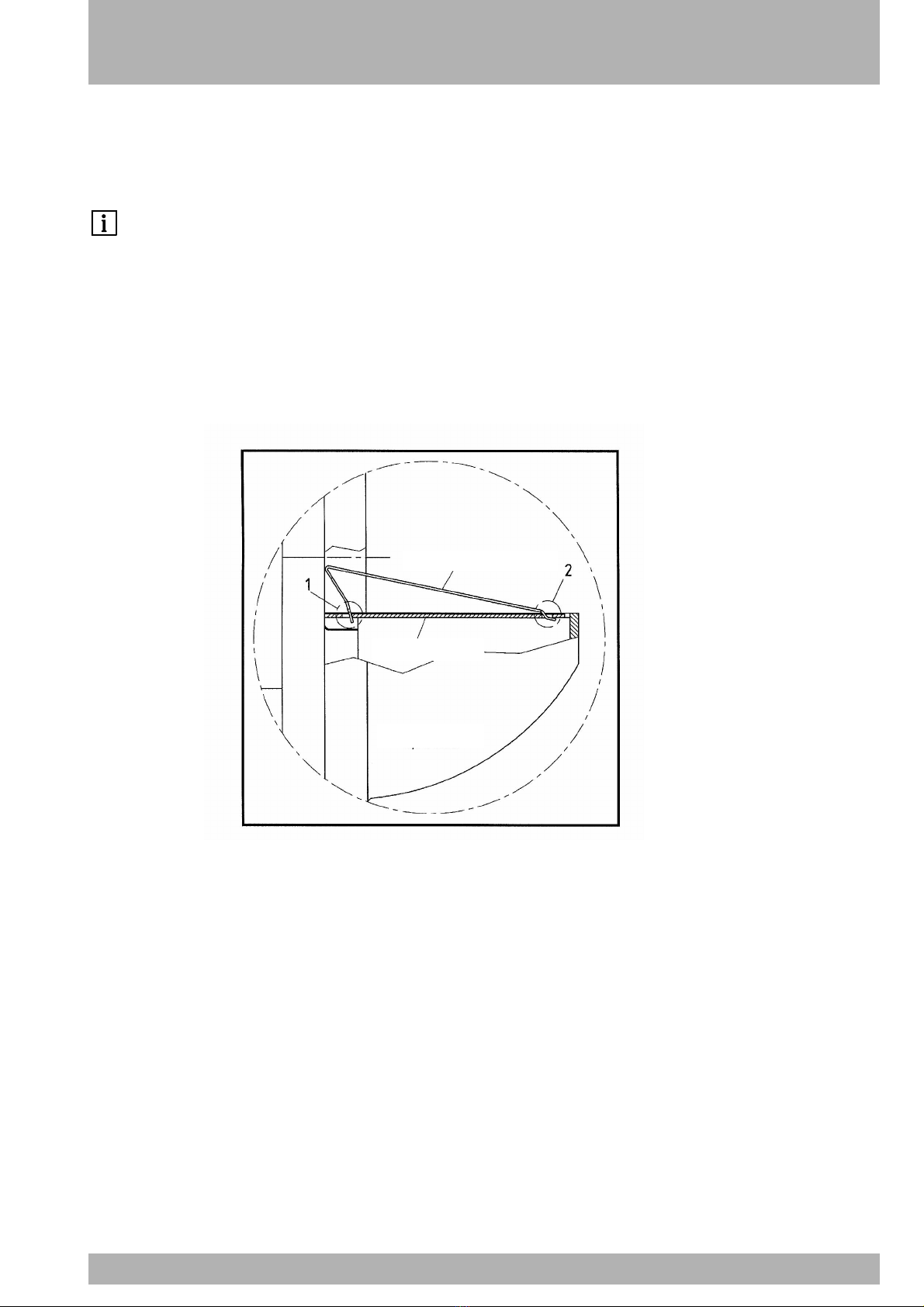

A 7.1 Fitting the diagonal support ..................................................................................................................7

A 7.2 Assembly ..............................................................................................................................................7

A 8 Taking care of the unit ................................................................................................................................8

A 8.1 Maintenance ........................................................................................................................................8

A 8.2 Troubleshooting ....................................................................................................................................8

A 8.3 Reconditioning the trimming disc ........................................................................................................8

A 8.4 Replacement trimming discs ................................................................................................................8

Warranty information ......................................................................................................................................9

Spare parts ..................................................................................................................................................10