-7-

Power On■

After installation is complete, turn the power on.

When using an optional chiller (HPC-20) and turning on the power for the power on, wait for 10 minutes

until water circulates completely. When warning “Chiller Water Current Abnormal” is displayed, turn

off and on. In the case of chiller abnormal warning due to improper piping of chiller or insufficient amount

of water, turn off the unit, check the connection, add water, and turn the unit back on again.

When using direct connection of water and error is displayed due to uncirculated or low flow, check

the water supply status.

Operation Panel■

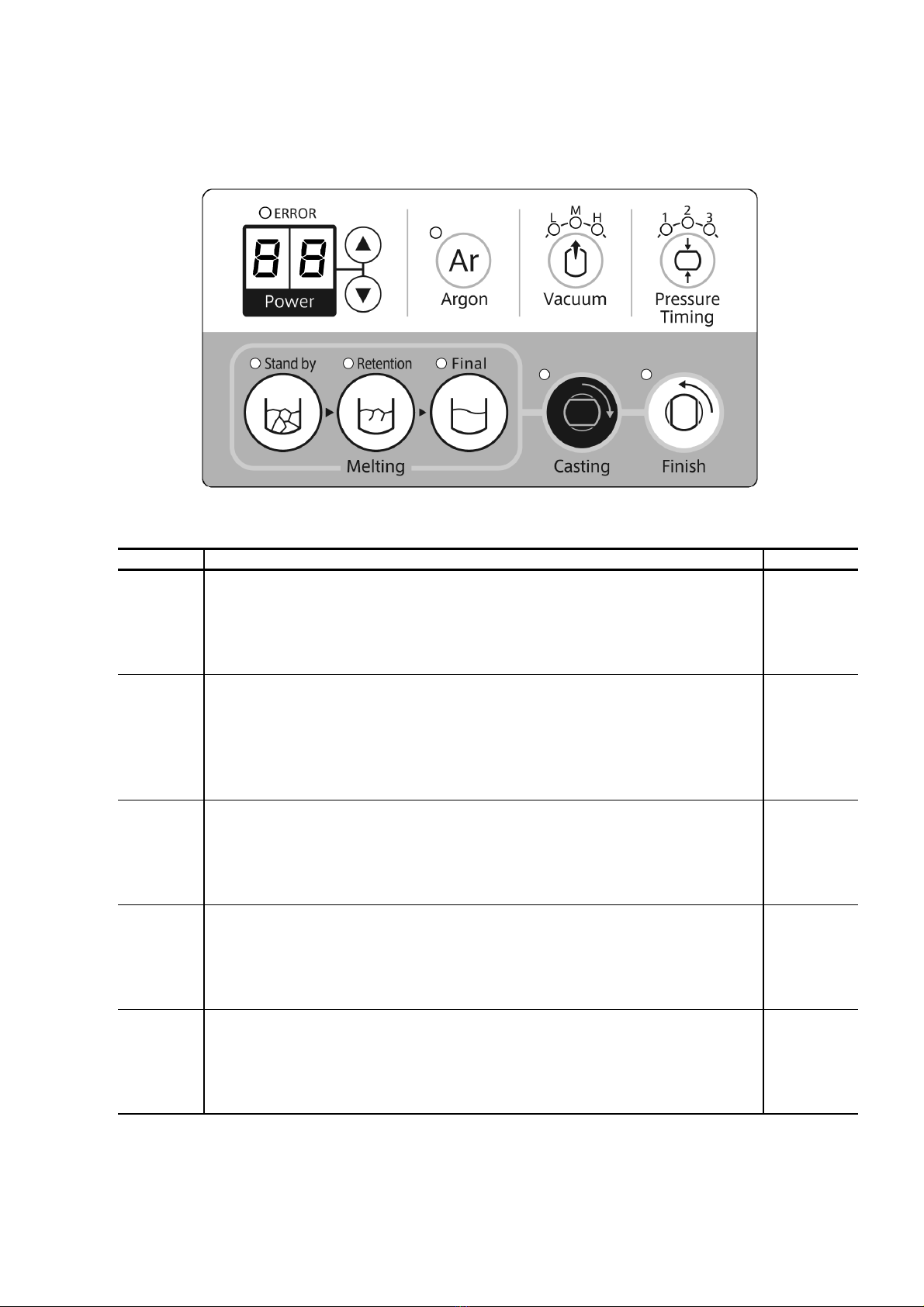

Display & Lamp●

ERROR Lamp When the unit is abnormal, the lamp will illuminate and error number will be・」「

displayed on 2-digit display.

Power Display High frequency power is displayed between 0 and 99%. Elapsed time is displayed・」「

during cooling of casting or when the unit is abnormal, error number is displayed.

Ar Lamp The lamp illuminates when argon gas is injected.・」「

L M H Lamp Vacuum level is displayed. The lamp will blink during vacuum operation.・、、」「

1 2 3 Lamp Pressure Timing is displayed. The lamp will blink during pressurization.・、、」「

Stand by Lamp The lamp will illuminate during Stand by Melting operation.・」「

Retention Lamp The lamp will illuminate during Retention Melting operation.・」「

Final Lamp The lamp will illuminate during Final Melting operation.・」「

Casting Lamp The lamp will illuminate when casting is available and blink during pressurization.・」「

Finish Lamp The lamp will illuminate during cooling.・」「

Buttons●

Change the high frequency power in increments of 5%.・ △、▽」「

Ar Is ON/OFF button to inject argon gas.・」「

Vacuum Change vacuum level.・」「

Pressure Timing Change pressure timing.・」「

Stand by ON/OFF button of Stand by Melting operation.・」「

Retention ON/OFF button of Retention Melting operation.Retention Melting・」「

Final ON/OFF button of Final Melting operation.・」「

Casting Pressthebuttontocastwithchamberinvertingandpressure.・」「

Finish After cooling time is finished, press the button to complete casting.・」「