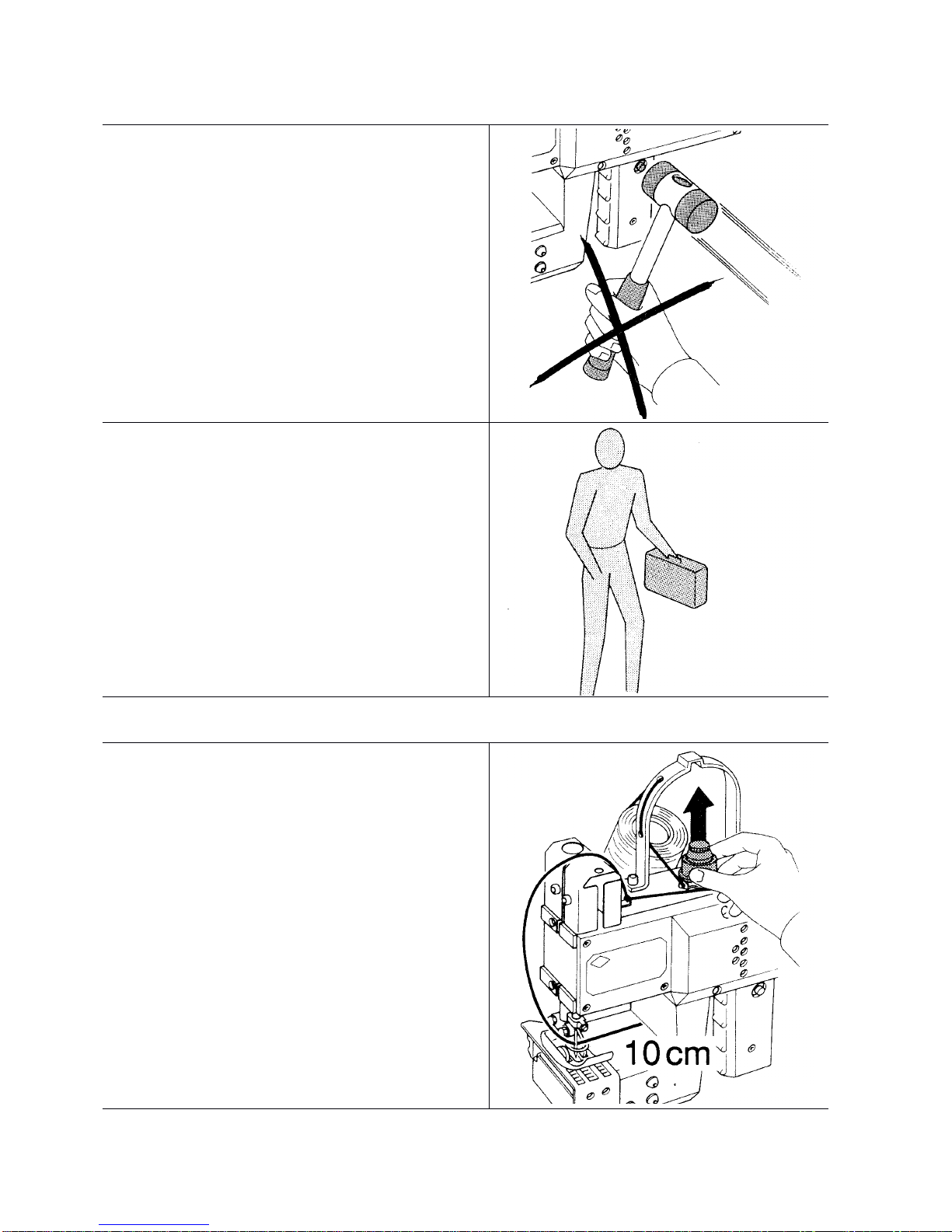

CHANGING THE NEEDLE

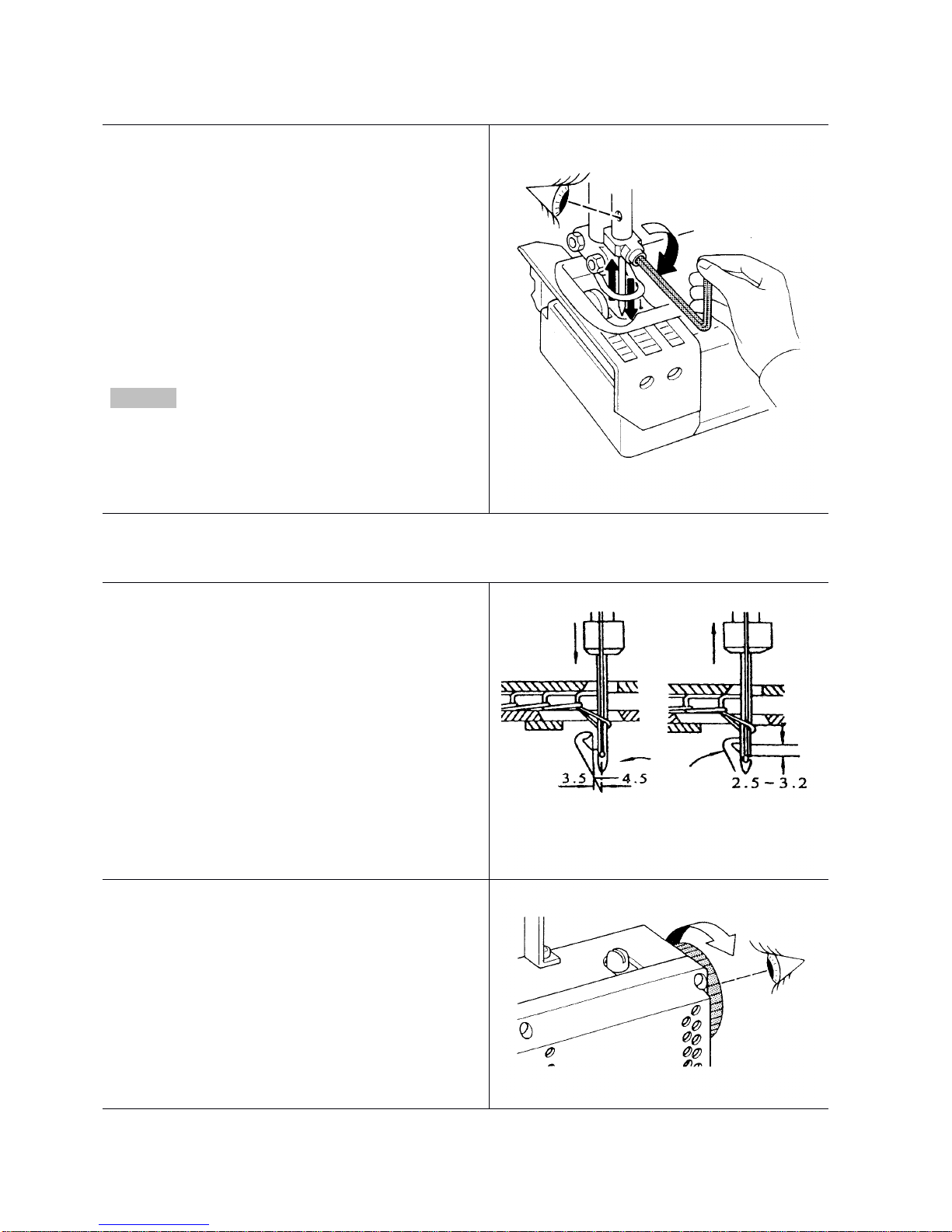

LOOPER AND NEEDLE ADJUSTMENTS

Loosen the screw for the needle and draw out

the needle. Insert the shank of the new needle as

far as it will go into the needle seat and with the

flat on the shank

facing to the front.

Retighten screw for the needle on the flat of the

needle shank and thread the needle eye.

Warning:

Pull out mains plug before changing the needle!

1. Needle position: When the needle goes to the

lowest position, the space between looper point

and needle center is about 3.5~4.5mm.

2. When the looper hook the thread loop which

shoot off by the needle. The space between

looper and needle not more than 0.2mm, the

space between looper point and needle eye is

about 2.5~3.2mm.

Turn motor handwheel in operating direction until

the needle is in its upmost position above the

throat plate.