Table of Contents

1. SAFETY INSTRUCTIONS .....................................................................................5

2. GENERAL DESCRIPTION.....................................................................................6

2.1 GENERAL ...........................................................................................................6

2.2 FEATURES..........................................................................................................6

2.3 SPECIFICATION..................................................................................................7

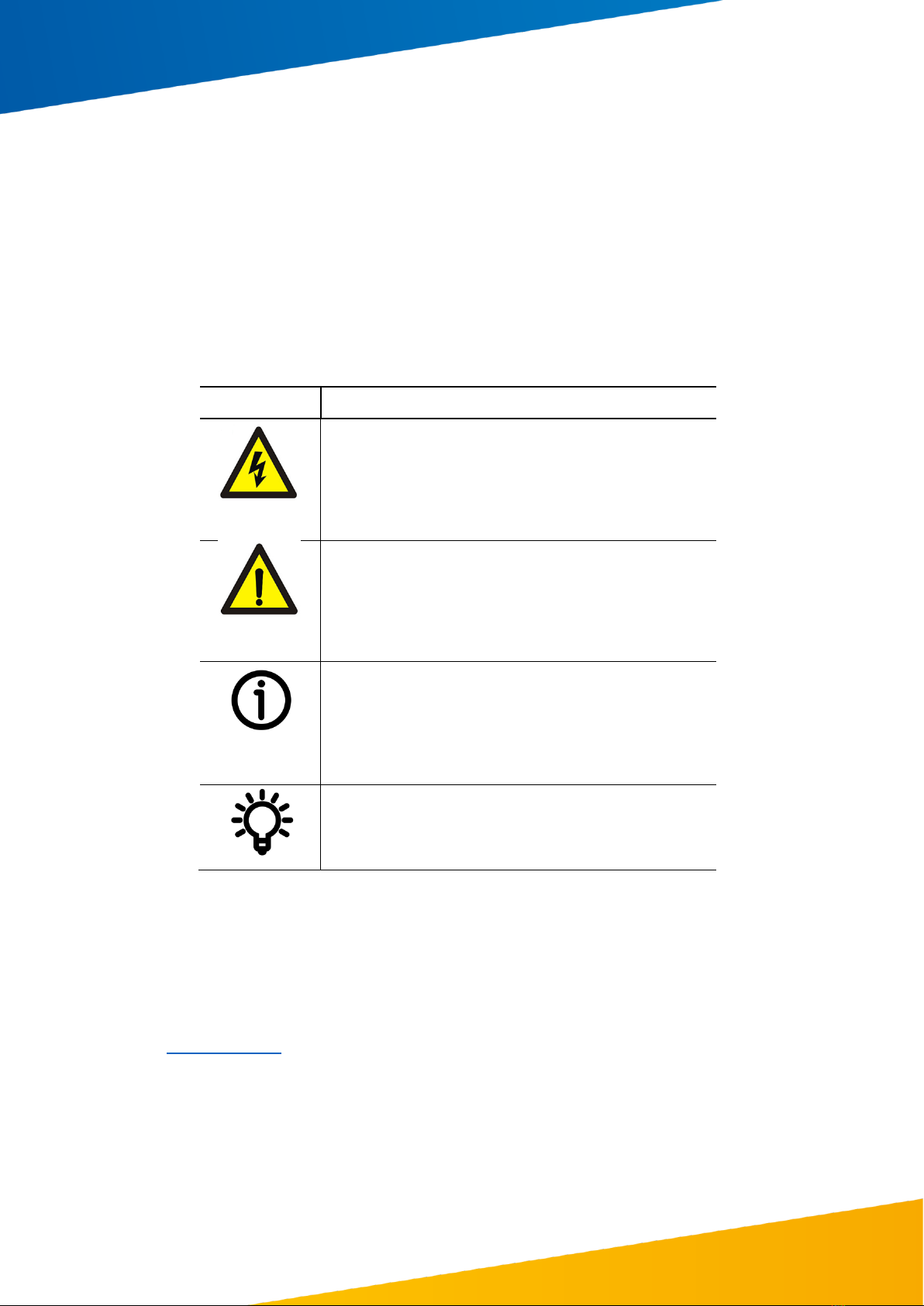

2.4 DEVICE COMPOSITION AND ACCESSORIES.......................................................8

3. SIGNAL TRANSMISSION METHODS...................................................................9

3.1 INTRODUCTION TO THE TWO OPERATING METHODS .....................................9

3.2 WIRING AND OPERATION FOR DIRECT CONNECTION....................................10

3.3 WIRING AND OPERATION OF CLAMP COUPLING METHOD ...........................12

4. CONNECTION MODES FOR CABLE IDENTIFICATION.......................................14

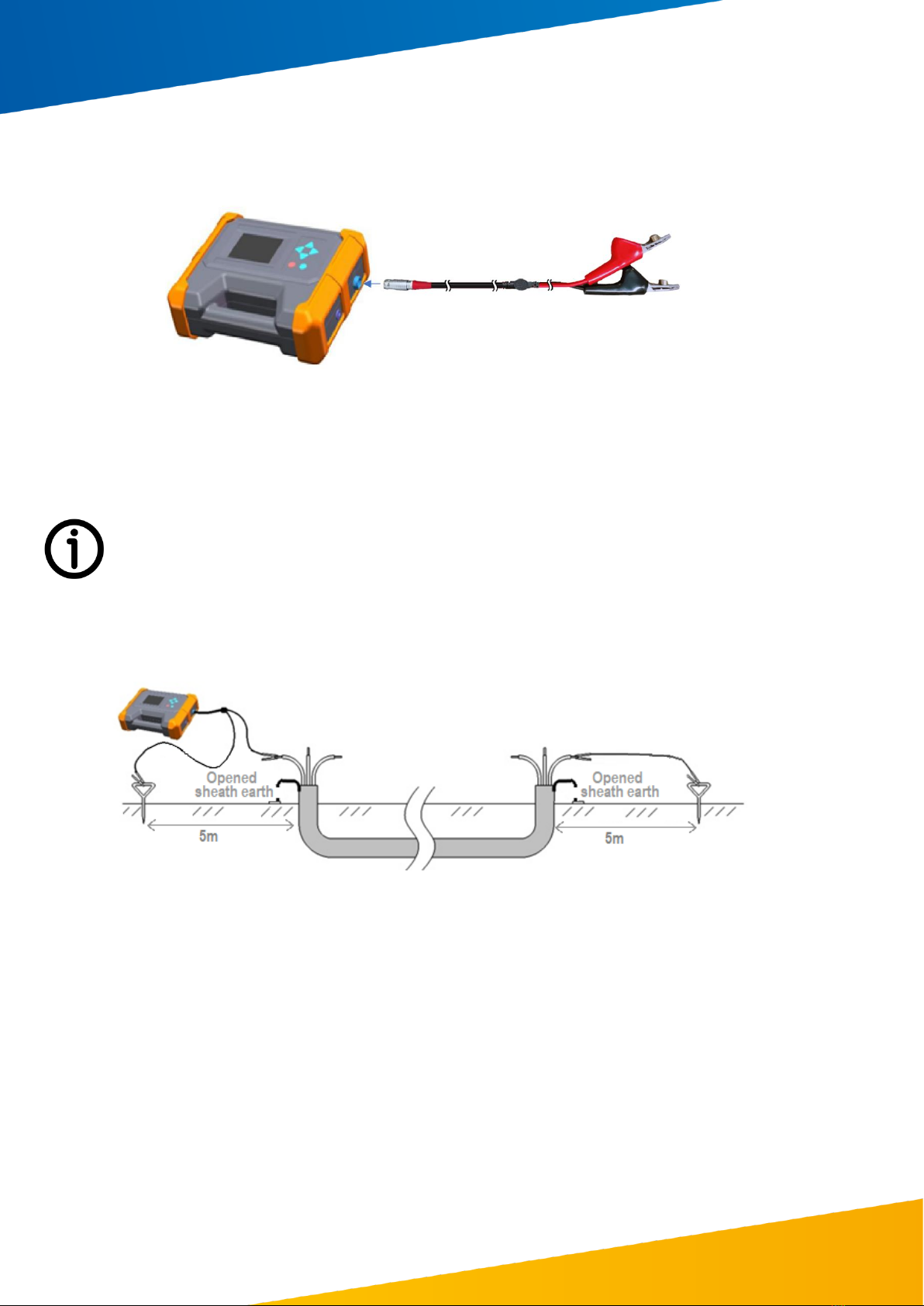

4.1 OUT OF SERVICE CABLE WIRING METHOD.....................................................15

4.2 LIVE CABLE WRING METHOD..........................................................................18

4.3 TRANSMISSION FREQUENCY SELECTION IN CABLE DETECTION.....................19

5. SMART CABLE IDENTIFICATION ......................................................................20

5.1 SELECTION OF SIGNAL TRANSMISSION METHOD...........................................20

5.2 RECEIVER FLEXIBLE SENSOR CONNECTION.....................................................20

5.3 INTRODUCTION TO THE RECEIVER INTERFACE...............................................20

5.4 CALIBRATION...................................................................................................21

5.5 CABLE IDENTIFICATION...................................................................................22

6. POWER FREQUENCY CURRENT MEASUREMENT............................................26

6.1 INTERFACE INTRODUCTION............................................................................26

6.2 POSITION ERROR.............................................................................................26

7. TRANSPORTATION AND STORAGE..................................................................27

7.1 TRANSPORTATION CONSIDERATIONS ............................................................27

7.2 STORAGE CONDITIONS AND PRECAUTIONS...................................................27

8. UNPACKING INSPECTION, MAINTENANCE AND WARRANTY .........................27

8.1 INITIAL CHECKS ...............................................................................................27

8.2 MAINTENANCE................................................................................................27

8.3 WARRANTY......................................................................................................28

8.4 PACKING LIST: .................................................................................................29