Prime Controls ECLIPSE EP200 User manual

EP200 Multi-Lane End Leak Detection System

Operating Instructions

202920 Revision E

4/13/2022

Prime Controls, Inc.

DESCRIPTION

The EP200 End Leak Detection System (ELDS) uses Prime Controls LH200H and SL100H

featuring Eclipse Leak Detection Technology to provide up to four lanes of light-based end leak

detection for conversion presses. The system can operate at up to 1000 ends per minute while

detecting holes and cracks as small as 0.5µm.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 i Revision E

Revision History

Revision Date Description Author

A 2021-05-03 Initial Release RMC

B 2021-05-21 Updated LH200H-3 Mechanical Drawings RMC

C 2021-06-21 Updated terminal block numbers 2401 -> 24X1 RMC

D 2021-11-02 Replaced LH200H-3 with LH200H-202 and LH200H-300.

Added SL100H-2

RMC

E 2022-04-13 Updated Troubleshooting sections, expanded installation

sections

BP

©Prime Controls, Inc.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 ii Revision E

Table of Contents

1 INTRODUCTION ................................................................................. 1

2 SYSTEM COMPONENTS .................................................................... 1

2.1 EP200 Chassis .................................................................................................. 1

2.1.1 Indicators ................................................................................................... 1

2.1.2 Interconnects ............................................................................................. 1

2.2 MI200 Touch Screen .......................................................................................... 1

2.3 SL100H-D LED Driver ........................................................................................ 2

2.4 PS506 Power Supply ......................................................................................... 2

2.5 CAP001 Power Filter ......................................................................................... 3

2.6 PLC001 Programmable Controller ..................................................................... 3

2.7 ET230 Ethernet Gateway (Option) ..................................................................... 4

2.8 LH200H or LH200H-opt Light Detector .............................................................. 4

2.9 SL100H-1 or SL100H-2 Remote LED Illuminator .............................................. 5

2.10 Cable Set ........................................................................................................... 6

2.11 Sensors and Actuators ....................................................................................... 7

3 INSTALLATION ................................................................................... 7

3.1 EP200 Chassis Mounting ................................................................................... 7

3.2 LH200H, LH200H-opt Mounting ......................................................................... 7

3.3 SL100H-1, SL100H-2 Mounting ......................................................................... 7

3.4 Wiring and Cabling............................................................................................. 7

3.4.1 Introduction ................................................................................................ 7

3.4.2 General Terminal Block Connections ...................................................... 12

3.4.3 AC Power ................................................................................................. 12

3.4.4 Press Controller Connections .................................................................. 12

Input Logic Signals .......................................................................................13

Output Logic Signals .....................................................................................13

Signal Polarities ............................................................................................13

3.4.4.3.1 Drop-In Replacement Wiring Configuration ................................................14

3.4.4.3.2 Fail Safe Wiring Configuration (Preferred) .................................................15

3.4.5 External Rejector Signals ......................................................................... 15

3.4.6 Internal Signals ........................................................................................ 15

3.4.7 Configuring System Parameters .............................................................. 16

4 OPERATION ..................................................................................... 21

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 iii Revision E

4.1 Power-Up Sequence ........................................................................................ 21

4.2 Power Troubleshooting .................................................................................... 21

5 USER INTERFACE ........................................................................... 23

5.1.1 MI200 Touch Screen Interface ................................................................. 23

5.1.2 MI200 Screen Elements ........................................................................... 23

5.1.3 Introduction .............................................................................................. 23

5.1.4 Menu Buttons ........................................................................................... 24

5.1.5 Toggle Buttons ......................................................................................... 24

5.1.6 Indicators ................................................................................................. 24

5.1.7 Changing Values ..................................................................................... 24

Numeric Keypad ...........................................................................................25

5.2 MI200 Screens ................................................................................................. 26

5.2.1 Main Screen ............................................................................................. 26

System Operating No Status Messages........................................................26

5.2.1.1.1 Communication Status ...............................................................................26

5.2.1.1.2 System Status ...........................................................................................27

5.2.1.1.3 Measurement Results ................................................................................27

5.2.1.1.4 Lane Status ...............................................................................................28

5.2.1.1.5 Menu Login ................................................................................................28

5.2.1.1.6 Password Entry .........................................................................................29

5.2.1.1.7 Menu Select ..............................................................................................29

5.2.1.1.8 Menu Log Out ............................................................................................30

5.2.1.1.9 Help ...........................................................................................................30

5.2.1.1.10 Main Screen with Status Message ...........................................................31

5.2.1.1.11 Main Screen with Leak Reset ..................................................................31

5.2.2 Leak Log Screen ...................................................................................... 32

5.2.3 Measurement Log Screen ........................................................................ 33

5.2.4 System Status Screen ............................................................................. 33

5.2.5 System History Screen ............................................................................ 34

5.2.6 Lane Status Screen ................................................................................. 35

5.2.7 Lane History Screen ................................................................................ 36

5.2.8 Main Menu ............................................................................................... 37

Setup ............................................................................................................38

5.2.8.1.1 Limits .........................................................................................................38

5.2.8.1.2 Phasing .....................................................................................................39

5.2.8.1.3 Configure IO ..............................................................................................41

Default Settings ...................................................................................41

IO Enable/Disable Switch ....................................................................41

IO Polarity ...........................................................................................41

IO Drive Type ......................................................................................42

Lane Reject (Result) Mode ..................................................................42

5.2.8.1.3.5.1 ELTP Drop-In-Replacement Settings ............................................44

5.2.8.1.3.5.2 ELDS Fail-Safe Signal Settings ....................................................44

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 iv Revision E

5.2.8.1.4 Rejector .....................................................................................................45

5.2.8.1.5 Parameters ................................................................................................45

5.2.8.1.6 Configure PLC ...........................................................................................46

IO Enable/Disable Switch ....................................................................46

IO Polarity ...........................................................................................47

5.2.8.1.6.2.1 ELTP Drop-In-Replacement Settings ............................................48

5.2.8.1.6.2.2 ELDS Fail-Safe Signal Settings ....................................................48

Diagnostics ...................................................................................................49

5.2.8.2.1 Lane Force IO ............................................................................................49

IO Force Enable/Disable Switch ..........................................................50

IO Polarity ...........................................................................................50

IO Signal State ....................................................................................50

5.2.8.2.2 Configure Internal IO .................................................................................50

IO Enable/Disable Switch ....................................................................51

IO Polarity ...........................................................................................51

IO Drive Type ......................................................................................51

5.2.8.2.2.3.1 ELTP Drop-In-Replacement Settings ............................................52

5.2.8.2.2.3.2 ELDS Fail-Safe Signal Settings ....................................................52

5.2.8.2.3 Version ......................................................................................................53

5.2.8.2.4 Measurement Screen ................................................................................53

5.2.8.2.5 Statistics Screen ........................................................................................54

5.2.8.2.6 Force PLC001 IO Screen...........................................................................55

IO Force Enable/Disable Switch ..........................................................55

IO Polarity ...........................................................................................55

IO Signal State ....................................................................................56

Utility Menu ...................................................................................................56

5.2.8.3.1 Load Defaults ............................................................................................57

5.2.8.3.2 Modbus Address ........................................................................................57

5.2.8.3.3 Modbus Counts .........................................................................................58

5.2.8.3.4 Internal Diagnostics ...................................................................................60

5.2.8.3.5 Set Date ....................................................................................................60

5.2.8.3.6 Set Time ....................................................................................................61

5.2.8.3.7 Limits .........................................................................................................61

6 MODBUS COMMUNICATION ........................................................... 63

6.1 Serial Interface ................................................................................................. 63

6.2 LH200H Commands ........................................................................................ 63

6.2.1 Discrete Coil Outputs (000001) ................................................................ 64

6.2.2 Discrete Inputs (100001) .......................................................................... 66

6.2.3 Register Inputs (300001) ......................................................................... 67

6.2.4 Holding Registers (400001) ..................................................................... 68

6.3 PLC001 Commands......................................................................................... 69

6.3.1 Discrete Coil Outputs (000001) ................................................................ 69

6.3.2 Discrete Inputs (100001) .......................................................................... 72

6.3.3 Register Inputs (300001) ......................................................................... 73

6.3.4 Holding Registers (400001) ..................................................................... 73

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 v Revision E

7 MAINTENANCE ................................................................................ 74

7.1 Light Head Gasket and Bushing Replacement ................................................ 74

8 TROUBLESHOOTING ....................................................................... 75

8.1 Basic Guide ..................................................................................................... 75

8.2 Diagnostic Messages ....................................................................................... 76

8.3 Indicators ......................................................................................................... 78

8.3.1 PS506 ...................................................................................................... 78

8.3.2 LH200H .................................................................................................... 79

8.3.3 SL100H-D ................................................................................................ 79

8.3.4 PLC001 .................................................................................................... 80

8.3.5 Rejector Relays ....................................................................................... 82

8.4 Detailed Instructions ........................................................................................ 82

8.4.1 #x NOK .................................................................................................... 82

8.4.2 DMA COMP NOK – DMA START NOK ................................................... 82

8.4.3 #X Timing NOK ........................................................................................ 82

8.4.4 #x Watchdog NOK ................................................................................... 83

8.4.5 Strobe NOK ............................................................................................. 83

8.4.6 Modbus Communication Troubleshooting................................................ 84

Incorrect or Broken Wiring (Individual Lane with HMI) ...................................84

Duplicate Modbus Address ...........................................................................84

Incorrect Modbus Address ............................................................................84

8.4.6.3.1 HMI Detecting Method ...............................................................................85

8.4.6.3.2 Serial Terminal Method ..............................................................................85

9 REPLACING ECLIPSE SYSTEM COMPONENTS ............................ 86

9.1 Power Down Prior to Maintenance .................................................................. 86

9.2 LH200H/LH200H-opt Replacement ................................................................. 86

9.3 SL100H-1 or SL100H-2 Remote LED Illuminator Replacement ...................... 86

9.4 SL100H-D Replacement .................................................................................. 87

9.5 PLC001 Programmable Controller Replacement ............................................. 87

9.6 CAP001 Replacement ..................................................................................... 87

9.7 PS506 Power Supply Replacement ................................................................. 88

10 FACTORY ASSISTANCE .................................................................. 88

11 OPERATING SPECIFICATIONS ....................................................... 89

12 ELECTRICAL SPECIFICATIONS ..................................................... 90

13 LIMITATIONS AND EXCLUSION OF WARRANTIES ....................... 91

14 ACRONYMS ...................................................................................... 92

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 vi Revision E

15 GENERAL TERMINAL BLOCK CONNECTIONS ............................. 94

15.1 Wiring and Cabling........................................................................................... 94

15.1.1 Introduction .............................................................................................. 94

15.1.2 LH200H, LH200H-opt Connections ......................................................... 99

15.1.3 SL100H-1, SL100H-2 Connections ........................................................ 100

16 DRAWINGS ..................................................................................... 101

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 vii Revision E

Table 1 – Cable Set ................................................................................................................... 6

Table 2 – Signal Drive Types ....................................................................................................16

Table 3 – Internal Signal Polarities ............................................................................................16

Table 4 – System Status List .....................................................................................................34

Table 5 – System History List ....................................................................................................35

Table 6 – Lane Status List ........................................................................................................36

Table 7 – Lane History List........................................................................................................37

Table 8 – Signal Polarities ........................................................................................................42

Table 9 – PLC IO Signals ..........................................................................................................46

Table 10 – Signal Polarities.......................................................................................................47

Table 11 – Internal IO Polarities ................................................................................................51

Table 12 – Result Bit Meanings ................................................................................................54

Table 13 – Modbus Counter Descriptions .................................................................................59

Table 14 – Modbus Counters Normal Operation .......................................................................59

Table 15 – Modbus Counters Trouble Shooting ........................................................................59

Table 16 – Modbus PSIO Terminal Block Connections .............................................................63

Table 17 – Modbus Command Codes .......................................................................................63

Table 18 – Modbus Discrete Coils.............................................................................................64

Table 19 – Modbus Discrete Inputs ...........................................................................................66

Table 20 – Modbus Register Inputs ...........................................................................................67

Table 21 – Modbus Holding Registers ......................................................................................68

Table 22 – Modbus Command Codes .......................................................................................69

Table 23 – Modbus Discrete Coil Outputs .................................................................................69

Table 24 – Modbus Discrete Inputs ...........................................................................................72

Table 25 – Modbus Register Inputs ...........................................................................................73

Table 26 – Modbus Holding Registers ......................................................................................73

Table 27 – Maintenance Parts ..................................................................................................74

Table 28 – PLC001 Indicators ...................................................................................................80

Table 29 – PSIO Terminal Block External Connection List ........................................................94

Table 30 – LHSL Terminal Block Connection List .....................................................................95

Table 31 – LH200H/LH200H-opt Connection List ......................................................................99

Table 32 – SL100H-1, SL100H-2 Connection List ................................................................... 100

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 viii Revision E

Figure 1 – MI200 Touch Screen ................................................................................................. 2

Figure 2 – SL100H-D LED Driver ............................................................................................... 2

Figure 3 – PS506 Power Supply ................................................................................................ 3

Figure 4 – CAP001 Power Filter ................................................................................................. 3

Figure 5 – PLC001 ..................................................................................................................... 4

Figure 6 – ET230 Ethernet Gateway .......................................................................................... 4

Figure 7 – LH200H ..................................................................................................................... 5

Figure 8 – LH200H-202 or LH200H-300 .................................................................................... 5

Figure 9 – SL100H-1 Remote LED Illuminator ........................................................................... 6

Figure 10 - SL100H-2 Remote LED Illuminator .......................................................................... 6

Figure 11 – MI200 Screen Elements .........................................................................................23

Figure 12 – MI200 Menu Buttons ..............................................................................................24

Figure 13 – Numeric Keypad .....................................................................................................25

Figure 14 – Main Screen ...........................................................................................................26

Figure 15 – Main Screen System Status ...................................................................................27

Figure 16 – Main Screen Measurement Results ........................................................................27

Figure 17 – Main Screen Lane Status .......................................................................................28

Figure 18 – Main Screen Menu Login .......................................................................................28

Figure 19 – Password Entry Screen ..........................................................................................29

Figure 20 – Main Screen Menu Select ......................................................................................29

Figure 21 – Main Screen Menu Select ......................................................................................30

Figure 22 – Main Screen Help ...................................................................................................30

Figure 23 – Main Screen Status Message .................................................................................31

Figure 24 – Main Screen Leak Reset ........................................................................................31

Figure 25 – Main Screen Leak Reset Active .............................................................................32

Figure 26 – Leak Log Screen ....................................................................................................32

Figure 27 – Measurement Log Screen ......................................................................................33

Figure 28 – System Status Screen ............................................................................................33

Figure 29 – System History Screen ...........................................................................................34

Figure 30 – Lane Status Screen ................................................................................................35

Figure 31 – Lane History Screen ...............................................................................................36

Figure 32 – Main Menu Screen .................................................................................................37

Figure 33 – Setup Screen .........................................................................................................38

Figure 34 – Limits Screen .........................................................................................................38

Figure 35 – Phasing Screen ......................................................................................................39

Figure 36 – Phasing Screen Detail ............................................................................................40

Figure 37 – Configure IO Screen ..............................................................................................41

Figure 38 – ELTP Drop-In IO Configuration ..............................................................................44

Figure 39 – ELDS Fail Safe IO Configuration ............................................................................44

Figure 40 – Rejector Screen .....................................................................................................45

Figure 41 – Parameters Screen ................................................................................................45

Figure 42 – Configure PLC Screen ...........................................................................................46

Figure 43 – ELTP Drop-In IO Configuration ..............................................................................48

Figure 44 – ELDS Fail Safe IO Configuration ............................................................................48

Figure 45 – Diagnostics Menu Screen ......................................................................................49

Figure 46 – Lane Force IO Screen ............................................................................................49

Figure 47 – Configure IO Screen ..............................................................................................50

Figure 48 – ELTP Drop-In IO Configuration ..............................................................................52

Figure 49 – ELDS Fail Safe IO Configuration ............................................................................52

Figure 50 – Version Screen.......................................................................................................53

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 ix Revision E

Figure 51 – Measurement Screen .............................................................................................53

Figure 52 – Statistics Screen ....................................................................................................54

Figure 53 – Force PLC001 IO Statistics Screen ........................................................................55

Figure 54 – Utility Menu Screen ................................................................................................56

Figure 55 – Load Defaults Screen .............................................................................................57

Figure 56 – Modbus Address Screen ........................................................................................57

Figure 57 – Modbus Counts Screen ..........................................................................................58

Figure 58 – Internal Diagnostics Screen....................................................................................60

Figure 59 – Set Date Screen .....................................................................................................60

Figure 60 – Set Time Screen ....................................................................................................61

Figure 61 – Gain Bias Screen ...................................................................................................61

Figure 62 – PS506 LED Indicator ..............................................................................................78

Figure 63 – LH200H Indicators .................................................................................................79

Figure 64 – SL100H-D Indicators ..............................................................................................79

Figure 65 – PLC001 Indicators ..................................................................................................80

Figure 66 – Rejector Relay Indicator .........................................................................................82

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 1 Revision E

1 INTRODUCTION

The EP200 End Leak Detection System (ELDS) chassis supports one to four lanes of light-

based leak detection using LH200H, LH200H-202 or LH200H-300 Light Detectors and SL100H-

1 or SL100H-2 compact LED Illuminators. The system can operate at up to 1000 ends per

minute while detecting 0.5µm defects. A minimum installation requires only a single trigger pulse

from the Press Controller to initiate measurement during press dwell. A full system can take

advantage of the system’s Press Run input, measurement output, built-in rejector control, lane

measurement phasing, Ready Signal output, and optional Modbus or Ethernet/IP

communications.

2 SYSTEM COMPONENTS

The End Leak Detection System consists of nine major components as described below:

2.1 EP200 Chassis

The chassis uses an IP66 NEMA4 cabinet to house its power supplies, SL100H-D LED drivers

(one per lane), reject solenoid relays, and terminal blocks. A door-mounted 5.7” color touch-

panel provides set up and system monitoring capability for all four lanes. The chassis includes

two tool operated quarter-turn latches on the door to secure it.

2.1.1 Indicators

The EP200 has internal LED indicators for its PLC, reject solenoid relays, LED Illuminator

Drivers, and power supply.

2.1.2 Interconnects

The EP200 has connections to the LH200H or LH200H-opt and SL100H-1 or SL100H-2

detectors and illuminators, the reject solenoids, Press Controller, and AC mains.

2.2 MI200 Touch Screen

The MI200 is a 5.7” color touch screen, door mounted on the EP200 chassis. The touch screen

provides configuration, diagnostic, and status reporting for the system.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 2 Revision E

Figure 1 – MI200 Touch Screen

2.3 SL100H-D LED Driver

The SL100H-D drives the SL100H-1 or SL100H-2 remote LED illuminator. It provides constant

current drive to the LEDs and pulse confirmation to the LH200H to ensure correct leak detection

operation.

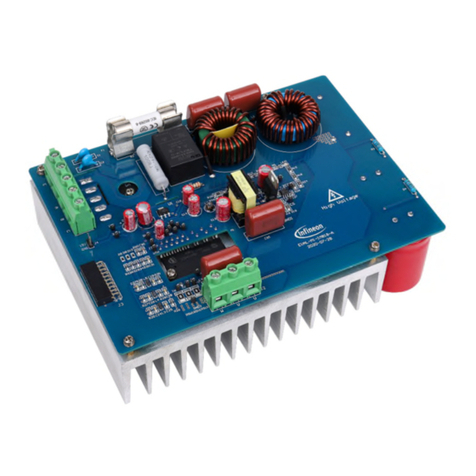

Figure 2 – SL100H-D LED Driver

2.4 PS506 Power Supply

The PS506 power supply of the system is a high current, +27V power supply selected for its

current handling capability and reliability. The assembly includes an externally mounted current

limiting resistor. The supply is adjusted to produce 27VDC. It is DIN rail mounted for ease of

service.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 3 Revision E

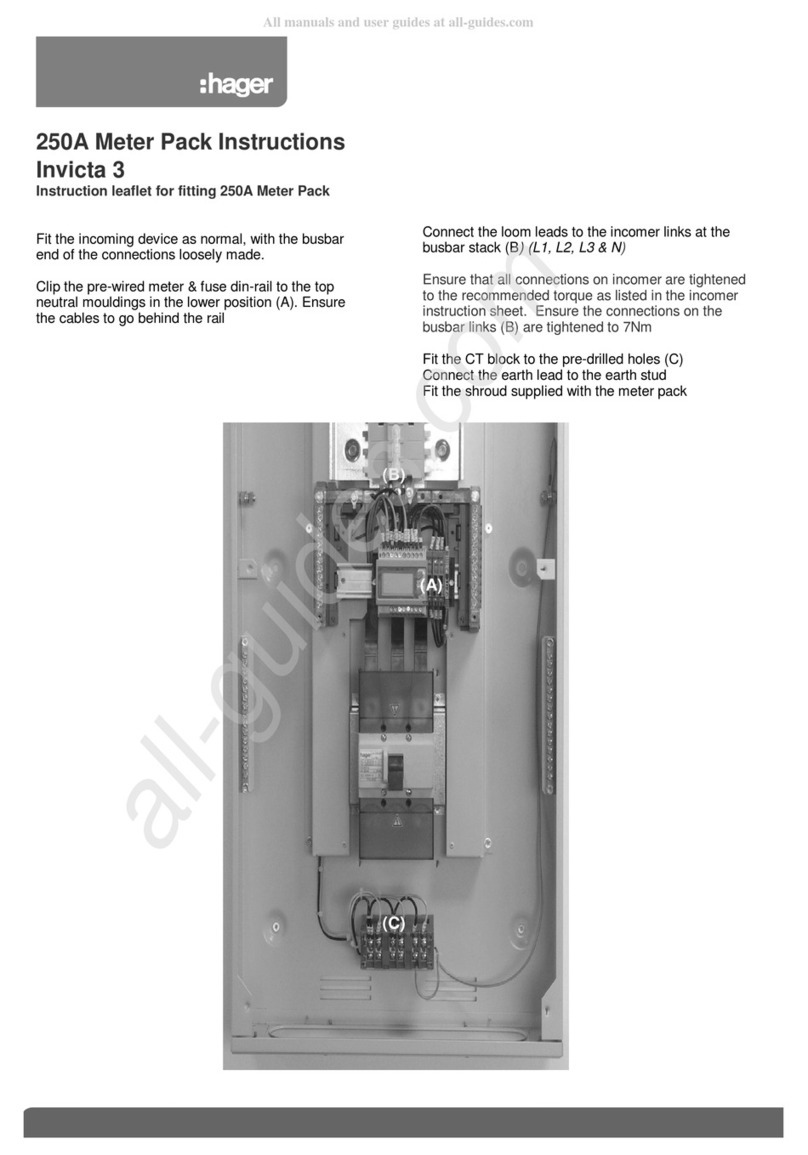

Figure 3 – PS506 Power Supply

2.5 CAP001 Power Filter

CAP001 provides current smoothing for the PS506 and SL100H-D LED drivers. It is DIN-rail

mounted for ease of service.

Figure 4 – CAP001 Power Filter

2.6 PLC001 Programmable Controller

The PLC001 controller integrates the signals from each detector into a common set of signals

for connection to the Press Controller. It also monitors all signals and each lane to ensure the

system is fully functional. PLC001 is configured using the HMI.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 4 Revision E

Figure 5 – PLC001

2.7 ET230 Ethernet Gateway (Option)

The ET230 can be used as an alternative to the MI200 touch screen. It translates the native

Modbus communication of the LH200H and PLC001 to Ethernet/IP.

Figure 6 – ET230 Ethernet Gateway

2.8 LH200H or LH200H-opt Light Detector

The system uses LH200H or LH200H-opt light detectors based on Prime Controls’ proprietary

Eclipse Leak Detection Technology. One detector is used per lane. These detectors are

designed to work in the hostile industrial environment of a conversion press while detecting

leaks down to 0.5µm. The LH200H is packaged to mechanically match the Prime Controls

LH200 light detectors, while the LH200H-opt is packaged to mechanically match a common

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 5 Revision E

mounting interface used in the industry. The nomenclature LH200H-opt refers to either the

LH200H-202 or LH200H-300 detectors optimized for 202 or 300 sized ends respectively.

Figure 7 – LH200H

Figure 8 – LH200H-202 or LH200H-300

2.9 SL100H-1 or SL100H-2 Remote LED Illuminator

The system uses the SL100H-1 or SL100H-2 compact remote all-solid-state LED based

illumination source for the system. One SL100H-1 or SL100H-2 is used per lane.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 6 Revision E

Figure 9 – SL100H-1 Remote LED Illuminator

Figure 10 - SL100H-2 Remote LED Illuminator

2.10 Cable Set

The following cables are used in the system:

Table 1 – Cable Set

Name Part Number Description Note

CBL144-10 202807-10 Connector/Cable, 12 pole, F PUR,

Shielded, 10M

EP200 to LH200H or

LH200H-opt

CBL145-10 202806-10 Connector/Cable, 12 pole, F PUR,

Shielded, 10M

EP200 to SL100H-1

or SL100H-2

202928-2 202829-2 MI101 Display Cable, 2M EP200 to MI200

CBL142-2 202568 MI1000 Power Cable, 2M EP200 to MI200

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 7 Revision E

The customer is responsible for cables to the reject solenoids, Press Controller, and AC power

source.

2.11 Sensors and Actuators

In addition to the LH200H or LH200H-opt and SL100H-1 or SL100H-2 mounted on the machine,

the customer may supply a reject solenoid (actuator) to reject failed can ends from the product

flow by using a blast of air or other means to remove a leaking end from the outfeed conveyor.

3 INSTALLATION

Prior installation of any components, verify that power is off to the unit and lock-outs are in place

per workplace safety policies.

3.1 EP200 Chassis Mounting

The EP200 enclosure is wall-mounted using four 7.62mm (.300”) holes on its back face. See

section 16 for drawing 202924 for details.

3.2 LH200H, LH200H-opt Mounting

The LH200H is mounted using four 6.75mm (0.266”) holes on a 69.85mm (2.75”) bolt circle. The

unit should be shock-mounted to reduce vibration transmitted to the unit from the press. See

section 16 for drawing 202690 for details.

The LH200H-opt is mounted using four 6.75mm (0.266”) holes on a 117.48mm (4.625”) bolt

circle. See section 16 for drawing 202798 at the back of this document for details. Shim the unit

to achieve proper contact with ends as they pass under the detector.

3.3 SL100H-1, SL100H-2 Mounting

The SL100H-1 is mounted using a single ¼-20 x 0.50” stud. See section 16 for drawing 202801

for details. Orient the cable direction to simplify cable routing.

The SL100H-2 is mounted using 4 ¼-28 socket head cap screws. See section 16 for drawing

202993 for details. Orient the cable direction to simplify cable routing.

3.4 Wiring and Cabling

3.4.1 Introduction

Refer to section 16 for drawing 202912 for system wiring and cabling details. The system has

two sets of DIN rail mounted terminal blocks in the EP200 chassis for interconnection purposes.

The horizontal power entry and Press Controller interconnect rail is designated PSIO while the

vertical detector/illuminator connection rail is designated LHSL. The connections to the PSIO rail

between the EP200 System and the Press Controller are listed below.

For a full list of terminal connections on the EP200 System, refer to Section 15.

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 8 Revision E

IO Connections needed for MINIMUM INSTALL CONFIGURATION

SIGNAL USE PRESS

CONTROLL

ER

TERMINAL

TO EP200

PSIO RAIL

TERMINA

L

NOTE TEST

READ

TRIGGER

Signal to EP200

that Press is in

dwell, take

measurement

700 (C) Initiates

measurement

by EP200

System

Toggle at Press

PLC -

Visible at

EP200 PLC

Z1-X6 (24VDC)

PC_IO_POW

ER (+)

+24V for inputs

from Press

Controller

PLC + +24V for inputs

from Press

Controller

DMM

24VDC

differential

between

Press ELDS IO

Power and Gnd

terminals

PLC+/PLC-

PC_IO_POW

ER (-)

Common for

inputs from Press

Controller

PLC - Common for

inputs from

Press

Controller

PE Protective Earth

Ground PE (D) GREEN/YELL

OW

DMM at EP200

PE (C)

NEUTRAL AC Neutral ACN (D) WHITE DMM at EP200

CAN (C)

AC LINE SYSTEM

POWER CB1 (A) BLACK

90-260VAC

47-63Hz

POWER

DMM at EP200

CB1 (A)

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 9 Revision E

The following IO connections are optional for the FULL SYSTEM INSTALLATION

CONFIGURATION

SIGNAL USE PRESS

CONTROLL

ER

TERMINAL

TO EP200

PSIO RAIL

TERMINA

L

NOTE TEST

PRESS RUN Signal to EP200

that the Press is

running normally

201 Signal to

EP200 that the

Press is

running

normally

Toggle at Press

PLC – Press Run

Visible at

EP200 PLC Z1-

X5 LED

LANE 1

REJECT

Signal to Press to

activate Rejector

Lane 1 / Track

leak counts

(leak detected)

305 (C) Used for Press

controlled

rejector

Toggle at EP200

-IO Config:

Rejector for Lane

1

Visible at Press

PLC rejector

input – Lane 1

(24VDC)

LANE 2

REJECT

Signal to Press to

activate Rejector

Lane 2 / Track

leak counts

(leak detected)

405 (C) Used for Press

controlled

rejector

Toggle at EP200

-IO Config:

Rejector for Lane

2

Visible at Press

PLC rejector

input – Lane 2

(24VDC)

LANE 3

REJECT

Signal to Press to

activate Rejector

Lane 3 / Track

leak counts

(leak detected)

505 (C) Used for Press

controlled

rejector

Toggle at EP200

-IO Config:

Rejector for Lane

3

Visible at Press

PLC rejector

input – Lane 3

(24VDC)

LANE 4

REJECT

Signal to Press to

activate Rejector

Lane 4 / Track

leak counts

(leak detected)

605 (C) Used for Press

controlled

rejector

Toggle at EP200

-IO Config:

Rejector for Lane

4

Visible at Press

PLC rejector

input – Lane 4

(24VDC)

FAULT Signal to Press

that there is a

problem with the

EP200 System

202 Used to stop

Press due to

EP200

Problem

Toggle at EP200

– IO PLC: Fault

Sig

Visible at Press

PLC Fault Input

(24VDC)

EP200 Multi-Lane End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202836 10 Revision E

READY

SIGNAL

Signal to Press

that EP200

System is ready

for

measurements

204 Used to

prevent Press

start without

measurement

Toggle at EP200

– IO PLC:

Ready Signal

Visible at Press

PLC Ready

Signal input

(24VDC)

EXCESS

REJECT

OUT

Signal to Press

when Reject Limit

is exceeded

203 (D) Used to stop

Press when

excess rejects

detected

Toggle at EP200

– IO PLC: Ready

Signal

Visible at Press

PLC Excess

Reject input

(24VDC)

ELDS IO

POWER (-)

GND

Common for

outputs to Press

Controller

2400 (D) Common for

outputs to

Press

Controller

DMM

24VDC

differential

between

Press ELDS IO

Power and Gnd

terminals

ELDS IO

POWER (+)

24V

+24V for outputs

to Press

Controller

2402 (D) +24V for

outputs to

Press

Controller

EXT HMI

MODBUS A

MODBUS A

between external

HMI and EP200

301 (D) For External

Modbus

communication

s

DMM

Verify continuity

between EP200

panel and Press

Controller

EXT HMI

MODBUS B

MODBUS B

between external

HMI and EP200

302 (D) For External

Modbus

communication

s

DMM

Verify continuity

between EP200

panel and Press

Controller

EXT HMI

CHASSIS PE

External HMI

chassis PE PE (D) For External

Modbus

communication

s

DMM

Verify continuity

between EP200

panel and Press

Controller

EXT HMI

COMMON

GND

Externa HMI

common GND 2400 (C) For External

Modbus

communication

s

DMM

Verify continuity

between EP200

panel and Press

Controller

Table of contents

Popular Measuring Instrument manuals by other brands

horiba

horiba LAQUAtwin-ORP-11 instruction manual

DH Instruments

DH Instruments MOLBLOC installation instructions

Hanna Instruments

Hanna Instruments HI97730 instruction manual

Ametek

Ametek CHANDLER ENGINEERING Twin UCA 4262 operating manual

SenseAir

SenseAir Go installation manual

Essilor

Essilor ALM 700 user guide