8 Setup improvements..................................................................................... 20

8.1

Error correction ................................................................................................20

8.2

Electrodes for solid dielectric material analysis.................................................21

8.2.1

Thin film electrodes or coating ........................................................................... 22

8.2.2

Guard electrodes................................................................................................ 22

8.3

Stable environment ..........................................................................................24

8.4

Shielding of low signal measurements .............................................................24

9 Installation ..................................................................................................... 25

9.1

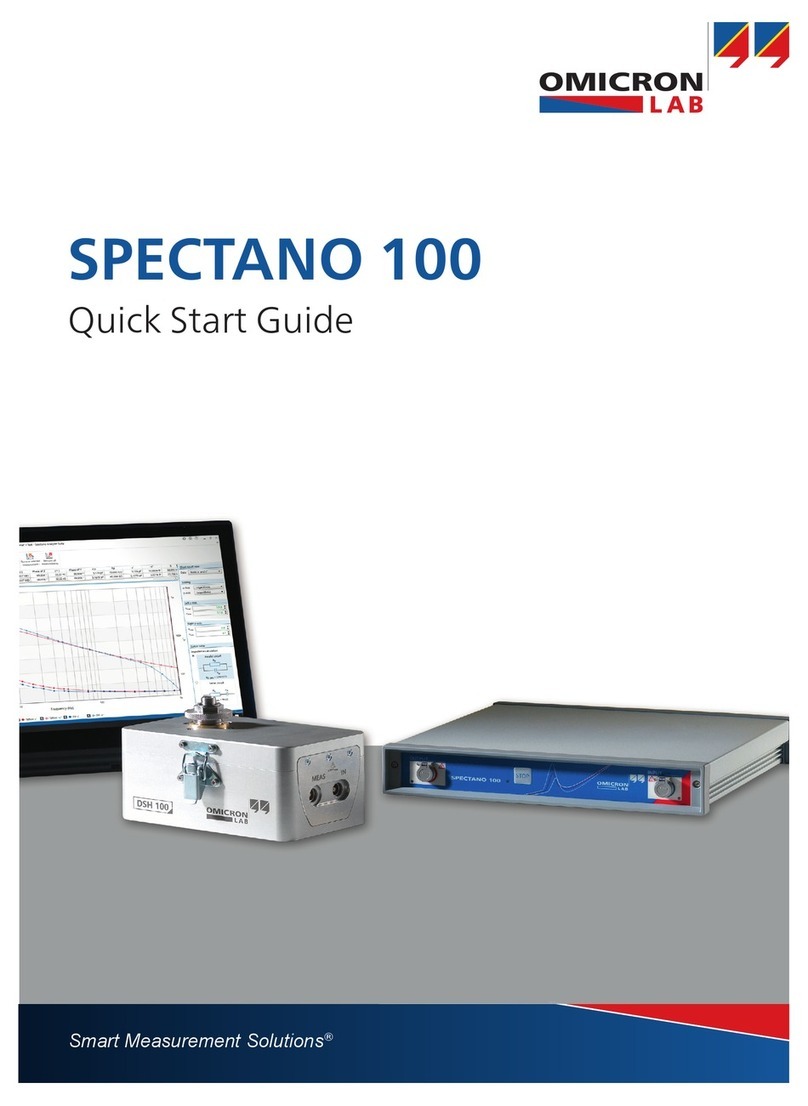

Install SPECTANO Analyzer Suite ....................................................................25

9.2

Power up SPECTANO 100...............................................................................26

9.3

Connect SPECTANO 100 to the computer .......................................................26

9.4

Connect SPECTANO 100 to a test object.........................................................27

9.4.1

Typical setup for a test cell with guard ring ........................................................ 30

9.4.2

Typical setup for a test cell without guard ring ................................................... 31

9.5

Connect SPECTANO 100 to the DTS1 dielectric test sample box.....................33

9.6

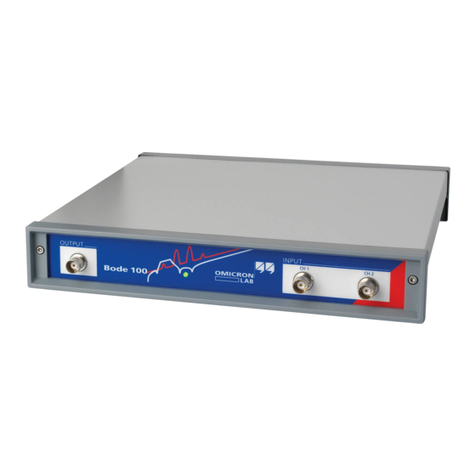

Connect SPECTANO 100 to Dielectric Sample Holder DSH 100…………… .. 34

10 SPECTANO Analyzer Suite ............................................................................... 35

10.1

Start view .........................................................................................................35

10.2

Create a new test .............................................................................................37

10.3

Perform measurements....................................................................................39

10.4

Perform reference measurements....................................................................42

10.4.1

Measurement procedure .................................................................................... 42

10.4.2

Correction procedure ......................................................................................... 46

10.4.3

Correction logic and calculation ......................................................................... 46

10.5

Perform analysis ..............................................................................................48

10.6

View measurement results ...............................................................................48

10.6.1

Numerical results................................................................................................ 49

10.6.2

Graphical result view.......................................................................................... 50

10.6.3

Result view controls ........................................................................................... 51

10.7

Settings............................................................................................................53

10.8

Commands.......................................................................................................59

10.9

Home view .......................................................................................................64

10.9.1

Chart render mode ............................................................................................. 66

10.9.2

Anti-Alias settings............................................................................................... 67

10.10

Load from the device........................................................................................67

10.10.1

Automatic load from the device.......................................................................... 67

10.10.2

Manual load from device .................................................................................... 67

11 Troubleshooting............................................................................................ 68

11.1

USB connection and/or power supply is missing ..............................................68

11.2

Lost communication .........................................................................................68

11.3

Measuring small capacitances – increased noise level.....................................68

11.4

Backup file .......................................................................................................69