When repair or change the wire, do not p lug the groun d wire into a flat outlet.

Do not alter groun d prong or use adapter.

The product require a 220V, 50/60 Hz circuit with a grou nding receptacle.

You may use a 3-wire, 2.5mm2(12 AWG) (minimum).

Long lengths of cords redu ce sprayer performance.

If you are not understand the statement of groun ding, please seek help of electrician.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and p aint fumes, in work area can ignite or explode.

To help prevent fire and explo sion:

Use equipment only in well ventilated area.

Eliminate all ignition so urces; such as p ilot lights, cigarettes, portable electric lamps,

and p lastic drop cloths (potential static arc).

Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for

flushing or cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

Keep work area free of debris, including solvent, rags, and gasoline.

Do not plug or un plug power cords or turn lights on or off when flammable fumes are

present.

Groun d equipment and conductive ob jects in work area. Read Grou nding instructions.

If there is static sparking or you feel a shock, stop operation immediately.Do not use

equipment until you identify and correct the problem.

Keep a fire extinguisher in the work area.

INJECTION HAZARD

High p ressure fluid from gun, hose leaks, or rup tured components will pierce skin. This

may look like just a cut, bu t it is a serious injury that can result in amputation. Get

immediate surgical treatment.

Do not point the gun at anyone or at any part of the body.

Do not put your hand over the spray tip.

Do not sto p or deflect leaks with your hand, bo dy, glove or rag.

Do not spray without tip gu ard and trig ger guard installed.

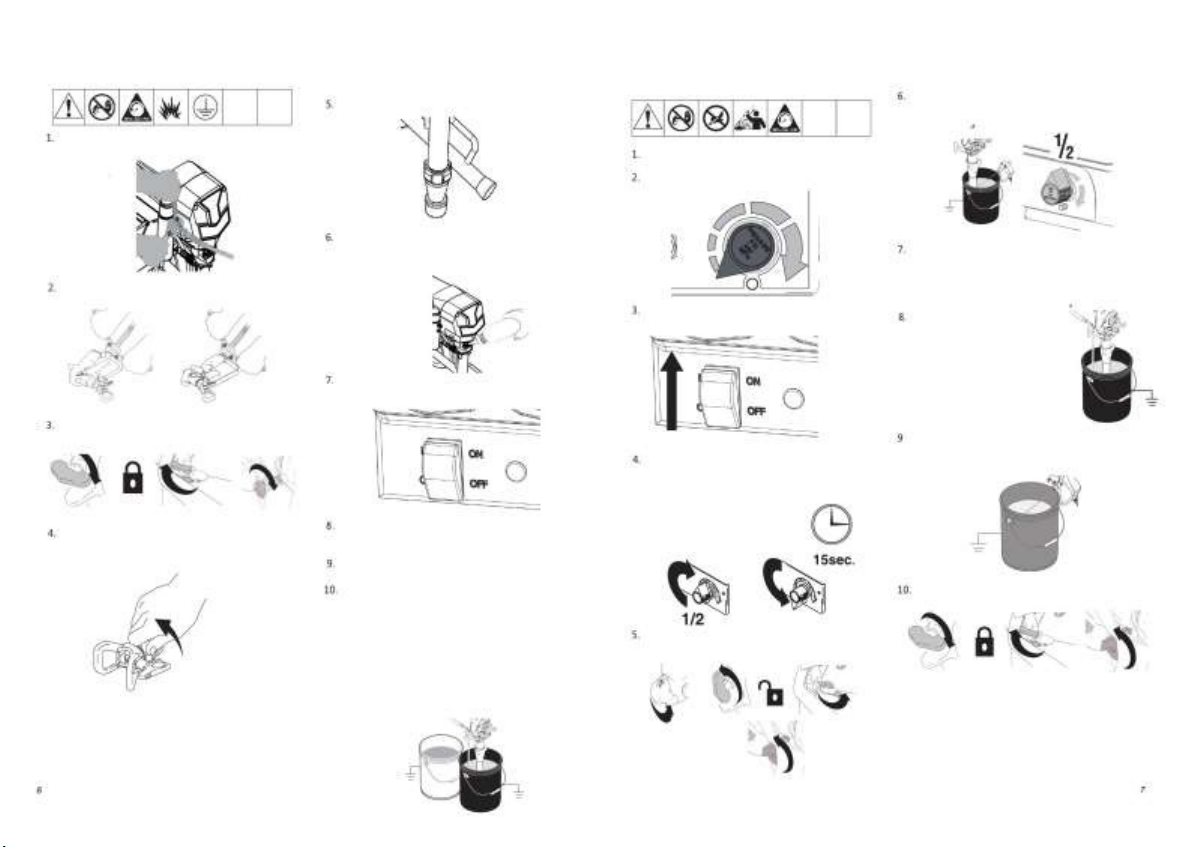

Engage trigg er lock when not spraying.

Follo w Pressure Relief Procedure in this manual, when yo u stop sprayin g and before

cleaning, checking, or servicing equipment.