Products, INC.

TR-134 System Service Manual

Sep 15/95

Page 2

AIR CONDITIONING SYSTEM - SYSTEM DESCRIPTION

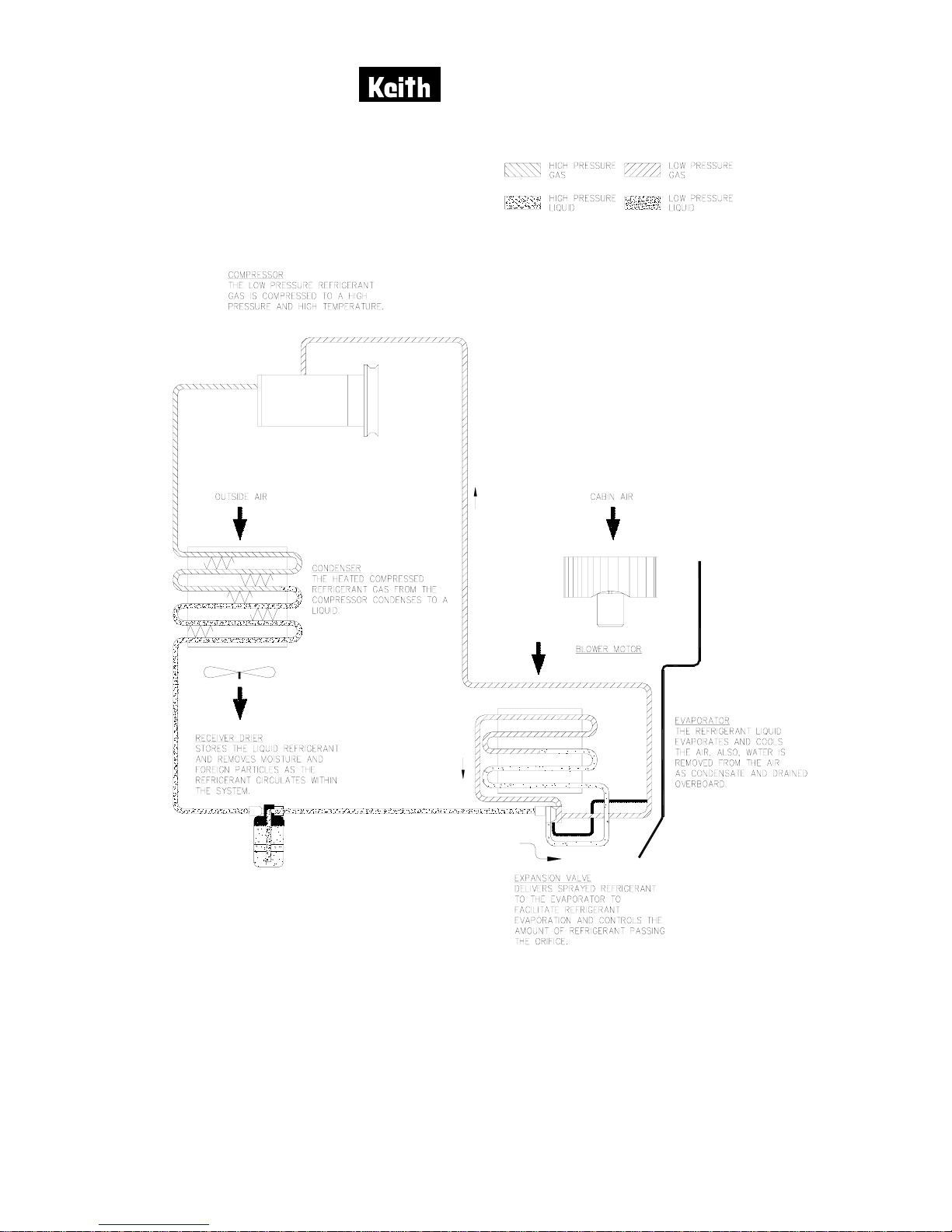

1. VAPOR CYCLE SYSTEM DESCRIPTION

The Keith Products vapor cycle air conditioning system uses liquid refrigerant

R134a to cool the aircraft cabin. The major components for the R134a air

conditioning system consists of a receiver/dryer, expansion valve, evaporator,

compressor and condenser to cool the aircraft cabin. Figure 1 shows an

operational schematic of the air conditioning system.

The receiver/drier stores liquid R134a refrigerant under pressure. The drier portion

of the assembly removes any traces of moisture that may have accumulated in the

system. Liquid refrigerant flows from the receiver drier through the expansion valve

where the refrigerant pressure is reduced, allowing it to spray into the evaporator.

At the same time, a blower driven by an electric motor passes air over the

evaporator. This air is cooled since heat is removed from the air by the evaporation

of the refrigerant in the evaporator. The evaporator produces water due to

condensation. This water drains overboard through a line attached to the

evaporator cover.

The refrigerant leaves the evaporator as a gas. This gas is pumped by the

compressor, raising its pressure and temperature. This high temperature gas then

flows to the condenser. Cooling air, driven by another electric blower motor,

passes over the condenser, cooling and therefore condensing the refrigerant to a

liquid. The liquid refrigerant then enters the receiver/drier, repeating the process.

The plumbing which connects the compressor, condenser and the evaporators,

consists of rubber based hoses with a nylon barrier. The fittings are permanently

swaged onto the hoses. Some systems that have been converted from R12 to

R134a refrigerant use Barb Lok hose fittings. Fittings are either "o-ring" type or

use flared connections. Sealant is used on the fitting mating surfaces to prevent

refrigerant leaks. Two R134a service valves are sized differently to avoid incorrect

cross-connecting when gaining access to the plumbing for system recharging.

The compressor on Keith Products air conditioning systems is driven either by an

electrical motor, or by the engine. Listed below is a more detailed description of

electric and engine driven compressor systems.