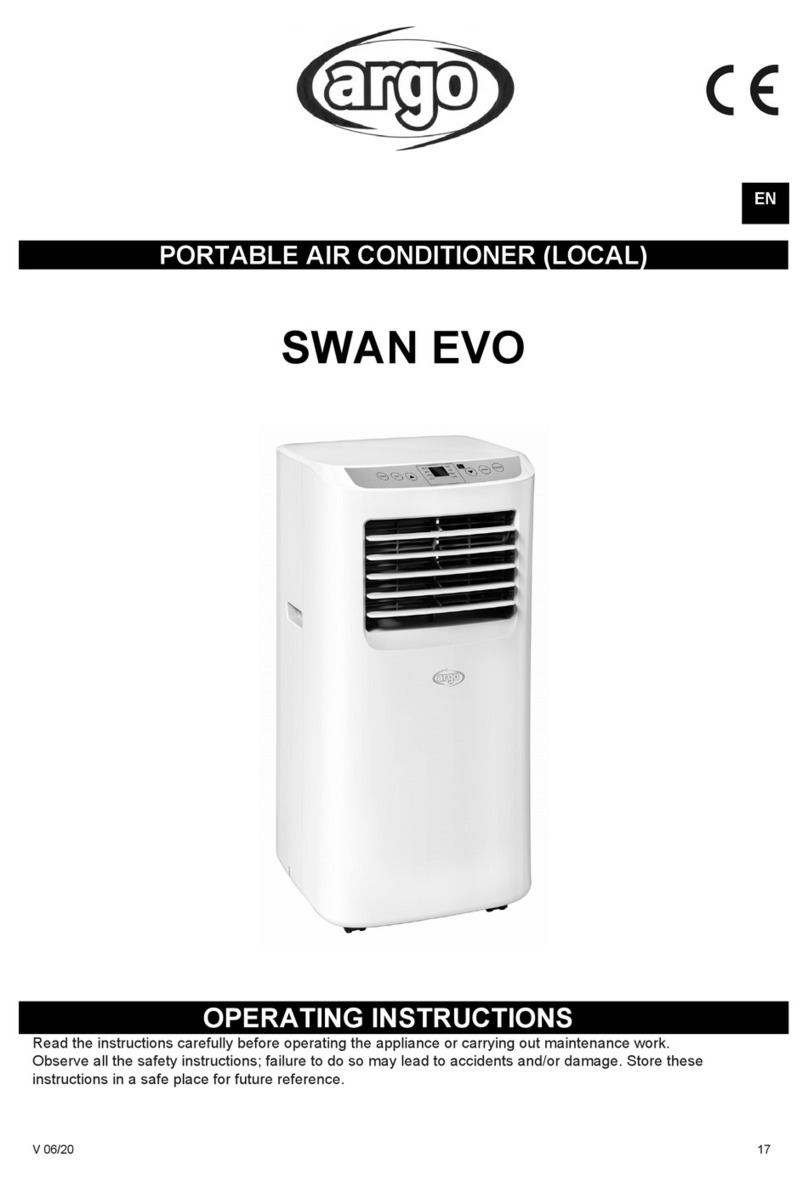

MegaLife NEBULA GREEN R32 Technical manual

Preparation before use 1

Safety Precautions 2

Display introduction

Installation instructions 6

Installation diagram 6

Indoor unit installation 7

11

Select the installation locations 7

Maintenance 10

10

11

Troubleshooting

Protection

1

Safety instructions

8

9

9

Connecting of the cable

Outdoor unit installation

9

Air purging

Wiring diagram

Remote controller operating instructions.See"remote controller

instructions".

Contents

1

Safety instructions

Preparation before use

1. To guarantee the unit work normally, please read

the manual carefully before installation, and try to

install strictly according to this manual.

2. Do not let air enter the refrigeration system or

discharge refrigerant when moving the air conditioner.

3. Properly ground the air conditioner into the earth.

4. Check the connecting cables and pipes carefully,

make sure they are correct and firm before connecting

the power of the air conditioner.

5. There must be an air-break switch.

6. After installing, the consumer must operate the air

conditioner correctly according to this manual, keep a

suitable storage for maintenance and moving of the

air conditioner in the future.

7. Fuse of indoor unit:T3.15A 250VAC or T5A 250VAC.

Please refer to the screen printing on the circuit board

for the actual parameters, which must be consistent

with the parameters on the screen printing.

8. For 5K~13K models, fuse of outdoor unit:T15A

250VAC or T 20A 250VAC. Please refer to the screen

printing on the circuit board for the actual parameters,

which must beconsistent with the parameters on the

screen printing

9. For 14K~18K models, fuse of outdoor unit: T 20A

250VAC.

10. For 21K~36K models, fuse of outdoor unit: T 30A

250VAC.

11. The installation instructions for appliances that are

intended to be permanently connected to fixed wiring,

and have a leakage current that may exceed 10 mA,

shall state that the installation of a residual current

device (RCD) having a rated residual operating

current not exceeding 30 mA is advisable

12. Warning: Risk of electric shock can cause injury or

death: Disconnect all remote electric power supplies

before servicing.

13. The maximum length of the connecting pipe

between the indoor unit and outdoor unit should be

less than 5 meters. It will affect the efficiency of the

air conditioner if the distance longer than that length

14. This appliance is not intended for use by person

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.Children should be

supervised to ensure that they do not play with the

appliance.Cleaning and user maintenance shall not

be made by childrenwithout supervision

15. This appliance can be used by children aged from

8 years and above and personswith reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without

supervision.

16. The batteries in remote controller must be

recycled or disposed of properly. Disposal of Scrap

Batteries --- Please discard the batteries as sorted

municipal waste at the accessible collection point.

17. If the appliance is fixed wiring, the appliance

must be fitted with means for disconnection from the

supply mains having a contact separation in all poles

that provide full disconnection under over voltage

category III conditions, and these means must be

incorporated in the fixed wiring in accordance with

the wiring rules.

18. If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

19.The appliance shall be installed in accordance

with national wiring regulations.

20. Servicing shall only be performed as

recommended by the equipment manufacturer.

Maintenance and repair requiring the assistance of

other skilled personnel shall be carried out under the

supervision of the person competent in the use of

flammable refrigerants.

21. The appliance shall not be installed in the laundry

22.Regarding to installation, please refer to section

“Installation instructions”.

23. Regarding to maintenance, please refer to

section “Maintenance”.

24. For models using R32 refrigerant, piping

connection should be conducted on outdoor side.

Note

1. When charging refrigerant into the system, make

sure to charge in liquid state,if therefrigerant of the

appliance is R32.Otherwise, chemical composition

of refrigerant (R32) inside the system may change

and thus affect performance of the air conditioner

2. According to the character of refrigerant (R32,the

value of GWP is 675), the pressure of the tube is

very high, so be sure to be careful when you install

and repair the appliance.

3. If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

4. Installation of this product must be done by

experienced service technicians professional

installers only in accordance with this manual.

5. The temperature of refrigerant circuit will be high,

please keep the interconnection cable away from the

copper tube.

Preset

Before using the air conditioner, be sure to check

and preset the following.

1.Remote Control presetting

Each time after the remote control is replaced with

new batteries or is energized, remote control auto

presettingheat pump.If the air conditioner you

purchased is a Cooling Only one, heat pump remote

controller can also be used.

1

2. Back-light function (optional)

Hold down any button on remote control to activate

the back light. It automatically shuts off 10 seconds

later.

Note: Back-light is an optional function.

3. Auto Restart Presetting

The air conditioner has an Auto-Restart function.

of Remote Control

Safeguarding the environment

This appliance is made of recyclable or re-usable

material. Scrapping must be carried out in

compliance with local waste disposal regulations.

Before scrapping it, make sure to cut off the mains

cord so that the appliance cannot be re-used.

For more detailed information on handling and

recycling this product, contact your local

authorities who deal with the separate collection

of rubbish or the shop where you bought the

appliance.

SCRAPPING OF APPLIANCE

This appliance is marked according

to the European Directive 2012/19/EC,

Waste Electrical and Electronic

Equipment (WEEE).

This marking indicates that this

product should not be disposed with

other household wastes throughout

the EU. To prevent possible harm to

the environment or human health from

uncontrolled waste disposal,recycle it

responsibly to promote the sustainable reuse of

material resources. To return your used device,

please use the return and collection systems or

contact the retailer where the product was

purchased. They can take this product for

environmental safe recycling.

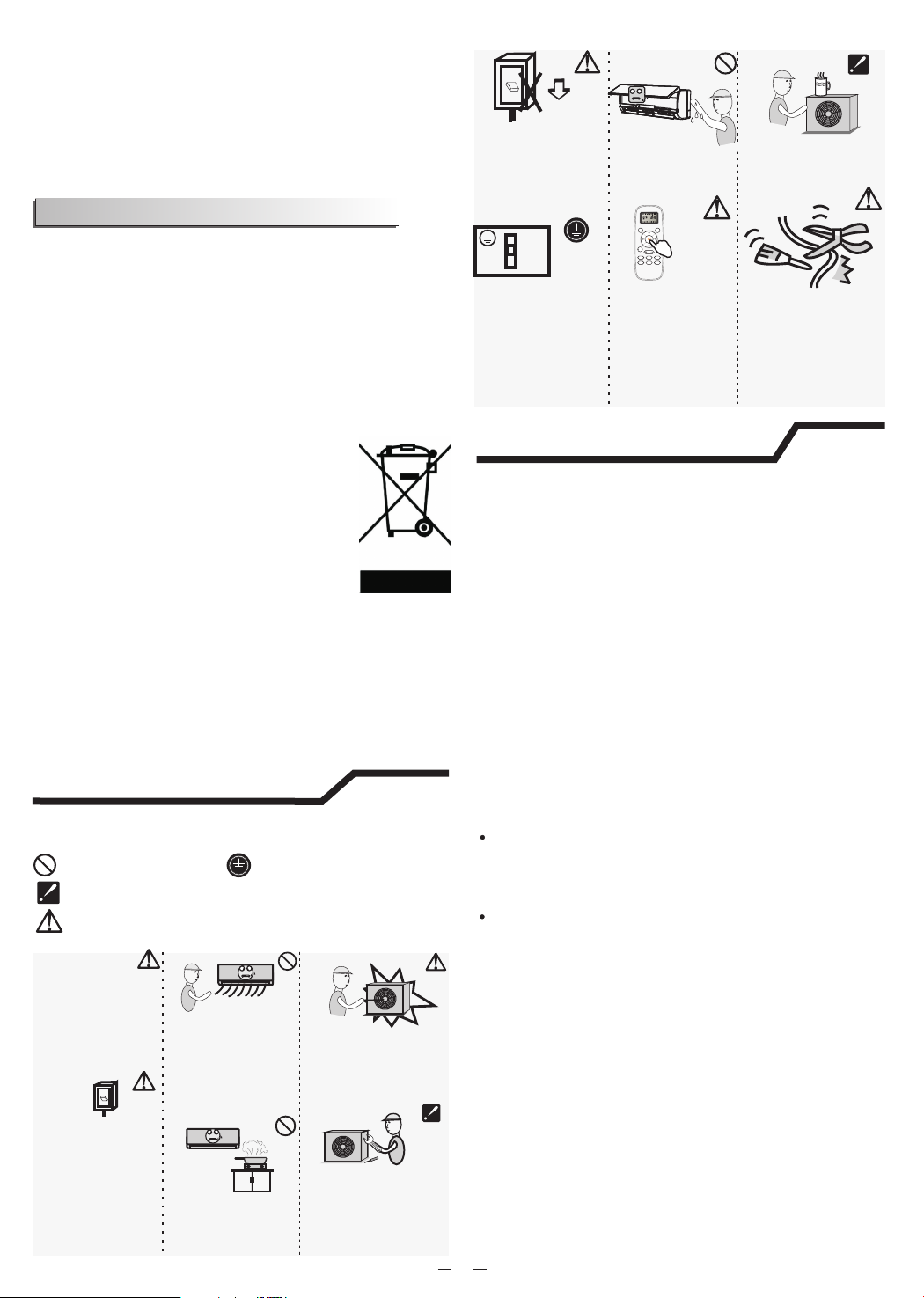

Safety precautions

Symbols in this Use and Care Manual are

interpreted as shown below.

Be sure not to do.

Pay attention to such a situation.

Grounding is essential.

Warning: Incorrect handling could cause a

serious hazard, such as death, serious injury, etc.

Do not use the power

supply circuit breaker

or pull off the plug to

turn it off during

operation. This may

cause a fire due to

spark, etc.

OFF

ON

It is the user's

responsibility to

make the appliance

be grounded

according to local

codes or ordinances

by a licenced

technician.

Do not touch the

operation buttons

when your hands

are wet.

Turn off the

applianceby remote

control firstly before

cutting off power

supply if malfunction

occurs.

ON

OFF

MODE

SMART

QUIET DIMMER

ECONOMY

FEEL

FAN SPEED

CLOCK

TIMER ON

TIMER OFF

SLEEP

TEMP.

TEMP.

SUPER

Use correct power

supply inaccordance

with the rating plate

requirement.

Otherwise, serious

faults or hazard may

occur or a fire maybe

break out.

Keep the power

supply circuit

breaker or plug from

dirt. Connect the

power supply cord to

it firmly and correctly,

lest an electric shock

or a fire break out

due to insufficient

contact.

OFF

ON

It is harmful to your

health if the cool air

reaches you for a long

time. It is advisable to

let the air flow be

deflected to all the

room.

Prevent the air flow

from reachingthe gas

burners and stove.

Never insert a stick or

similar obstacle to the

unit. Since the fan

rotates at high speed,

this may cause an injury.

Do not repair the

appliance by yourself.

If this is done

incorrectly, it may cause

an electric shock, etc.

Do not put any objects

on the outdoor unit.

Do not knit, pull or

press the power supply

cord, lest the power

supply cord be broken.

An electric shock or fire

is probably caused by

a broken power supply

cord.

2

Safety precautions

1.Transport of equipment containing

flammable refrigerants

Compliance with the transport regulations

2.Marking of equipment using signs

Compliance with local regulations

3.Disposal of equipment using flammable

refrigerants

Compliance with national regulations

4.Storage of equipment/appliances

The storage of equipment should be in

accordance with the manufacturer's

instructions.

5.Storage of packed (unsold) equipment

Storage package protection should be

constructed such that mechanical damage to

the equipment inside the package will not

cause a leak of the refrigerant charge.

The maximum number of pieces of equipment

permitted to be stored together will be

determined by local regulations.

6.Information on servicing

6-1 Checks to the area

Prior to beginning work on systems containing

flammable refrigerants, safety checks are

necessary to ensure that the risk of ignition is

minimised. For repair to the refrigerating

system, the following precautions shall be

complied with prior to conducting work on the

system.

6-2 Work procedure

Work shall be undertaken under a controlled

procedure so as to minimise the risk of

flammable gas or vapour being present while

the work is being performed.

Precautions for using R32 refrigerant

The basic installation work procedures are the

same as the conventional refrigerant(R22 or

R410A). However, pay attention to the following

points:

6-3 General work area

All maintenance staff and others working in the

local area shall be instructed

on the nature of work being carried out. Work

in confined spaces shall be avoided.

The area around the workspace shall be

sectioned off. Ensure that the conditions

within the area have been made safe by

control of flammable material.

6-4 Checking for presence of refrigerant

The area shall be checked with an appropriate

refrigerant detector prior to and during work,

to ensure the technician is aware of

potentially flammable atmospheres.

Ensure that the leak detection equipment

being used is suitable for use with flammable

refrigerants, i.e. non-sparking, adequately

sealed or intrinsically safe.

6-5 Presence of fire extinguisher

If any hot work is to be conducted on the

refrigeration equipment or any associated

parts, appropriate fire extinguishing equipment

shall be available to hand.

Have a dry powder or CO2 fire extinguisher

adjacent to the charging area.

6-6 No ignition sources

No person carrying out work in relation to a

refrigeration system which

involves exposing any pipe work that contains

or has contained flammable refrigerant shall

use any sources of ignition in such a manner

that it may lead to the risk of fire or explosion

All possible ignition sources, including

cigarette smoking, should be kept sufficiently

far away from the site of installation, repairing,

removing and disposal, during which

flammable refrigerant can possibly be released

to the surrounding space.

Prior to work taking place, the area around the

equipment is to be surveyed to

make sure that there are no flammable hazards

or ignition risks. “No Smoking” signs shall be

displayed.

6-7 Ventilated area

Ensure that the area is in the open or that it is

adequately ventilated before breaking into the

system or conducting any hot work.

A degree of ventilation shall continue during

the period that the work is carried out.

The ventilation should safely disperse any

released refrigerant and preferably expel it

externally into the atmosphere

.

6-8 Checks to the refrigeration equipment

Where electrical components are being

changed, they shall be fit for the purpose and

to the correct specification.

At all times the manufacturer's maintenance

and service guidelines shall be followed. If in

doubt consult the manufacturer's technical

department for assistance

The following checks shall be applied to

installations using flammable refrigerants:

–The charge size is in accordance with the

room size within which the refrigerant

containing parts are installed;

–The ventilation machinery and outlets are

operating adequately and are not obstructed;

–If an indirect refrigerating circuit is being

used, the secondary circuit shall be checked

for the presence of refrigerant;

–Marking to the equipment continues to be

visible and legible. Markings and signs that

are illegible shall be corrected;

–Refrigeration pipe or components are

installed in a position where they are unlikely

to be exposed to any substance which may

corrode refrigerant containing components,

unless the components are constructed of

materials which are inherently resistant to

being corroded or are suitably protected

against being so corroded.

6-9 Checks to electrical devices

Repair and maintenance to electrical

components shall include initial safety checks

and component inspection procedures.

If a fault exists that could compromise safety,

then no electrical supply shall be connected to

the circuit until it is satisfactorily dealt with.

If the fault cannot be corrected immediately

but it is necessary to continue operation, an

adequate temporary solution shall be used.

This shall be reported to the owner of the

equipment so all parties are advised.

Initial safety checks shall include:

–That capacitors are discharged: this shall be

done in a safe manner to avoid possibility of

sparking;

–That there no live electrical components and

wiring are exposed while charging,

recovering or purging the system;

–That there is continuity of earth bonding

7. Repairs to sealed components

During repairs to sealed components, all

electrical supplies shall be disconnected from

the equipment being worked upon prior to any

removal of sealed covers, etc.

If it is absolutely necessary to have an

electrical supply to equipment during

servicing, then a permanently operating form

of leak detection shall be located at the most

critical point to warn of a potentially hazardous

situation.

Particular attention shall be paid to the

following to ensure that by working on

electrical components, the casing is not

altered in such a way that the level of

protection is affected.

3

This shall include damage to cables,

excessive number of connections, terminals

not made to original specification, damage to

seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not

degraded such that they no longer serve the

purpose of preventing the ingress of flammable

atmospheres.

Replacement parts shall be in accordance with

the manufacturer's specifications.

NOTE:

The use of silicon sealant may inhibit the

effectiveness of some types of leak detection

equipment. Intrinsically safe components do

not have to be isolated prior to working on them.

8.Repair to intrinsically safe components

Do not apply any permanent inductive or

capacitance loads to the circuit without

ensuring that this will not exceed the

permissible voltage and current permitted for

the equipment in use.

Intrinsically safe components are the only

types that can be worked on while live in the

presence of a flammable atmosphere. The test

apparatus shall be at the correct rating.

Replace components only with parts specified

by the manufacturer. Other parts may result in

the ignition of refrigerant in the atmosphere

from a leak.

9.Cabling

Check that cabling will not be subject to wear,

corrosion, excessive pressure, vibration,

sharp edges or any other adverse

environmental effects.

The check shall also take into account the

effects of aging or continual vibration from

sources such as compressors or fans

10.Detection of flammable refrigerants

Under no circumstances shall potential

sources of ignition be used in the searching for

or detection of refrigerant leaks.

A halide torch (or any other detector using a

naked flame) shall not be used

11.Leak detection methods

The following leak detection methods are

deemed acceptable for systems containing

flammable refrigerants:

–Electronic leak detectors shall be used to

detect flammable refrigerants, but the

sensitivity may not be adequate, or may need

re-calibration. (Detection equipment shall be

calibrated in a refrigerant-free area.)

–Ensure that the detector is not a potential

source of ignition and is suitable for the

refrigerant used.

–Leak detection equipment shall be set at a

percentage of the LFL of the refrigerant and

shall be calibrated to the refrigerant employed

and the appropriate percentage of gas (25 %

maximum) is confirmed.

–Leak detection fluids are suitable for use with

most refrigerants but the use of detergents

containing chlorine shall be avoided as the

chlorine may react with the refrigerant and

corrode the copper pipe-work.

–If a leak is suspected, all naked flames shall

be removed/ extinguished.

–If a leakage of refrigerant is found which

requires brazing, all of the refrigerant shall be

recovered from the system, or isolated (by

means of shut off valves) in a part of the

system remote from the leak.

–Oxygen free nitrogen (OFN) shall then be

purged through the system both before and

during the brazing process.

12.Removal and evacuation

When breaking into the refrigerant circuit to

make repairs – or for any other purpose –

conventional procedures shall be used.

However, it is important that best practice is

followed since flammability is a consideration.

The following procedure shall be adhered to:

–Remove refrigerant;

–Purge the circuit with inert gas;

–Evacuate;

–Purge again with inert gas;

–Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into

the correct recovery cylinders.

The system shall be “flushed” with OFN to

render the unit safe.

This process may need to be repeated several

times.

Compressed air or oxygen shall not be used

for this task.

Flushing shall be achieved by breaking the

vacuum in the system with OFN and continuing

to fill until the working pressure is achieved,

then venting to atmosphere, and finally pulling

down to a vacuum.

This process shall be repeated until no

refrigerant is within the system. When the final

OFN charge is used, the system shall be

vented down to atmospheric pressure to

enable work to take place.

This operation is absolutely vital if brazing

operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is

not close to any ignition sources and there is

ventilation available.

13.Charging procedures

In addition to conventional charging

procedures, the following requirements shall

be followed:

–Ensure that contamination of different

refrigerants does not occur when using

charging equipment.

–Hoses or lines shall be as short as possible to

minimise the amount of refrigerant contained

in them.

4

–Cylinders shall be kept upright.

–Ensure that the refrigeration system is earthed

prior to charging the system with refrigerant.

–Label the system when charging is complete

(if not already).

–Extreme care shall be taken not to overfill the

refrigeration system.

Prior to recharging the system it shall be

pressure tested with OFN.

The system shall be leak tested on completion

of charging but prior to commissioning.

A follow up leak test shall be carried out prior

to leaving the site.

14.Decommissioning

Before carrying out this procedure, it is

essential that the technician is completely

familiar with the equipment and all its detail.

It is recommended good practice that all

refrigerants are recovered safely.

Prior to the task being carried out, an oil and

refrigerant sample shall be taken in case

analysis is required prior to re-use of

reclaimed refrigerant. It is essential that

electrical power is available before the task is

commenced.

a) Become familiar with the equipment and its

operation.

b) Isolate system electrically.

c) Before attempting the procedure ensure

that:

–Mechanical handling equipment is available,

if required, for handling refrigerant cylinders;

–All personal protective equipment is available

and being used correctly;

–The recovery process is supervised at all

times by a competent person;

–Recovery equipment and cylinders conform to

the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold

so that refrigerant can be

removed from various parts of the system.

f) Make sure that cylinder is situated on the

scales before recovery takes

place.

g) Start the recovery machine and operate in

accordance with manufacturer's instructions.

h) Do not overfill cylinders. (No more than

80 % volume liquid charge).

I ) Do not exceed the maximum working

pressure of the cylinder, even temporarily.

j ) When the cylinders have been filled

correctly and the process completed, make

sure that the cylinders and the equipment

are removed from site promptly and all

isolation valves on the equipment are

closed off.

k) Recovered refrigerant shall not be charged

into another refrigeration system unless it

has been cleaned and checked.

15.Labelling

Equipment shall be labelled stating that it has

been de-commissioned and emptied of

refrigerant.

The label shall be dated and signed.

Ensure that there are labels on the equipment

stating the equipment contain flammable

refrigerant.

16.Recovery

When removing refrigerant from a system,

either for servicing or decommissioning, it is

recommended good practice that all

refrigerants are removed safely.

When transferring refrigerant into cylinders,

ensure that only appropriate refrigerant

recovery cylinders are employed.

Ensure that the correct number of cylinders

for holding the total system charge is available

All cylinders to be used are designated for the

recovered refrigerant and labelled for that

refrigerant (i.e. special cylinders for the

recovery of refrigerant).

Cylinders shall be complete with pressure

relief valve and associated shut-off valves in

good working order.

Empty recovery cylinders are evacuated and,

if possible, cooled before recovery occurs.

The recovery equipment shall be in good

working order with a set of instructions

concerning the equipment that is at hand and

shall be suitable for the recovery of

flammable refrigerants.

In addition, a set of calibrated weighing scales

shall be available and in good working order.

Hoses shall be complete with leak-free

disconnect couplings and in good condition.

Before using the recovery machine, check

that it is in satisfactory working order, has

been properly maintained and that any

associated electrical components are sealed

to prevent ignition in the event of a refrigerant

release.

Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to

the refrigerant supplier in the correct recovery

cylinder, and the relevant Waste Transfer

Note arranged.

Do not mix refrigerants in recovery units and

especially not in cylinders.

If compressors or compressor oils are to be

removed, ensure that they have been

evacuated to an acceptable level to make

certain that flammable refrigerant does not

remain within the lubricant.

The evacuation process shall be carried out

prior to returning the compressor to the

suppliers.

5

Only electric heating to the compressor body

shall be employed to accelerate this process.

When oil is drained from a system, it shall be

carried out safely.

When moving or relocating the air conditioner,

consult experienced service technicians for

disconnection and reinstallation of the unit

Do not place any other electrical products or

household belongings under indoor unit or

outdoor unit. Condensation dripping from the

unit might get them wet, and may cause

damage or malfunction of your property.

Do not use means to accelerate the defrosting

process or to clean, other than those

recommended by the manufacturer.

The appliance shall be stored in a room

without continuously operating ignition

sources(for example, open flames, an

operating gas appliance or an operating

electric heater).

Do not pierce or burn.

Be aware that refrigerants may not contain an

odor.

To keep ventilation openings clear of

obstruction.

The appliance shall be stored in a

well-ventilated area where the room size

corresponds to the room area as specified for

operation.

The appliance shall be stored in a room

without continuously operating open

flames (for example an operating gas

appliance) and ignition sources (for example

an operating electric heater).

Any person who is involved with working on or

breaking into a refrigerant circuit should hold

a current valid certificate from an industry-

accredited assessment authority, which

authorises their competence to handle

refrigerants safely in accordance with an

industry recognised assessment specification.

Servicing shall only be performed as

recommended by the equipment manufacturer.

Maintenance and repair requiring the

assistance of other skilled personnel shall be

carried out under the supervision of the

person competent in the use of flammable

refrigerants.

Do not use means to accelerate the defrosting

process or to clean, other than those

recommended by the manufacturer.

Appliance shall be installed, operated and

stored in a room with a floor arealarger than

2

10 m .

The installation of pipe-work shall be kept to a

2

a room with a floor area largerthan 10 m .

The pipe-work shall be complianced with

national gas regulations.

The maximum refrigerant charge amount is

2.5 kg.The specific refrigerant charge is

based on the nameplate of the outdoor unit

Mechanical connectors used indoors shall

comply with ISO 14903. When mechanical

connectors are reused indoors, sealing parts

shall be renewed. When flared joints are

reused indoors, the flare part shall be

re-fabricated.

The installation of pipe-work shall be kept to

a minimum.

Mechanical connections shall be accessible

for maintenance purposes.

Installation must be performed in accordance with

the national wiring standards by authorized personnel only.

Above figure is only a simple presentation

of the unit, it may not match the external

appearance of the unit you purchased.

Explanation of symbols displayed on the indoor

unit or outdoor unit.

6

This symbol shows that this appliance

uses a flammable refrigerant.

If the refrigerant is leaked and exposed

to an external ignition source, there is a

risk of fire

This symbol shows that this appliance

usesa flammable refrigerant.

If the refrigerant is leaked and exposed

to an external ignition source, there is a

risk of fire

[symbol ISO

7010-W021

(2011-05)]

A2L symbol

[symbol ISO

7000-0790

(2004-01)]

[symbol ISO

7000-1659

(2004-01)]

[symbol ISO

1641-0790

(2004-01)]

This symbol shows that the operation

manual should be read carefully.

This symbol shows that a service

personnel should be handling this

equipment with reference to the

installation manual.

This symbol shows that information is

available such as the operating manual

or installation manual.

WARNING

WARNING

CAUTION

CAUTION

CAUTION

Caution, risk of fire

Waring;low burning

velocity material

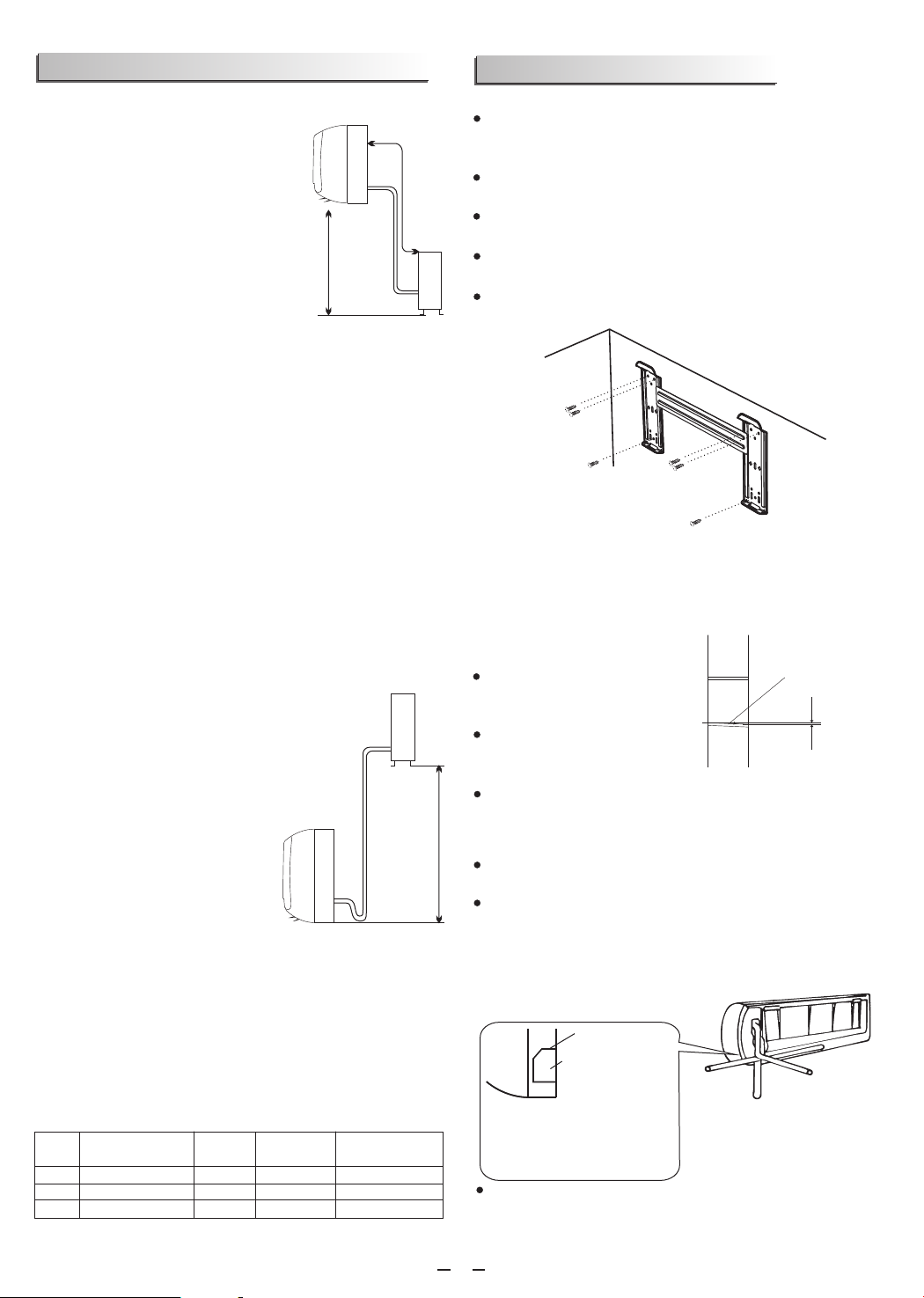

Select the installation locations

Location for Installing Indoor Unit

1. Where there is no obstacle near

the air outlet andair can be easily

blown to every corner.

2. Where piping and wall hole can

be easily arranged.

3. Keep the required space from

the unit to the ceiling and wall

according to the installation

diagram on previous page.

4. Where the air filter can be easily

removed.

5. Keep the unit and remote controller 1m or more

apart from television, radio etc.

6. Keep as far as possible from fluorescent lamps.

7. Do not put anything near the air inlet to obstruct it

from air absorption.

8. Install on a wall that is strong enough to bear the

weight of the unit.

9. Install in a place that will not increase operation

noise and vibration.

10. Keep away from direct sunlight and heating

sources. Do not place flammable materials or

combustion apparatuses on top of the unit.

Pipe length

is 15 meters

Max.

Height should

be less than 5m

Indoor unit

Outdoor

unit

Location for Installing Outdoor Unit

1. Where it is convenient to install and well ventilated.

2. Avoid installing it where flammable gas

could leak.

3. Keep the required distance

apart from the wall.

The pipe length between indoor and

outdoor unit should be not more than

5 meters in factory default status, but it

can go up to maximum 15 meters with

additional refrigerant charge.

6. Keep the outdoor unit away

from greasy dirt, vulcanization

gas exit.

7. Avoid installing it by the

roadside where there is a risk

of muddy water.

8. A fixed base where it is not subject to increased

operation noise.

9. Where there is not any blockage of the air outlet.

10. Avoid installing under direct sunlight, in an aisle

or sideway, or near heat sources and ventilation fans.

Keep away from flammable materials, thick oil fog,

and wet or uneven places.

If the height or pipe length is out of the scope of the

table, please consult the dealer.

Outdoor unit

Indoor unit

Pipe length is

15 meters Max.

be less than 5m

Height should

Model

5K~18K 515

Max. allowed pipe

length without additional

refrigerant (m)

Limit of

length (m)

pipe

21K 25K~

28K~36K

515

515

520

Limit of Elevation

Difference H (m)

Required amount of

additional refrigerant

(g/m)

530

540

Indoor unit installation

1. Installing the Mounting Plate

Decide an installing location for the mounting plate

according to the indoor unit location and pipe

direction.

Keep the mounting plate horizontally with a

horizontal ruler or level.

Drill holes of 32mm in depth on the wall for fixing

the plate.

Insert the plastic plugs to the hole, fix the mounting

plate with tapping screws.

Inspect if the mounting plate is well fixed. Then

drill a hole for pipe.

Mounting plate

Tapping screw

Note: The shape of your mounting plate may be different

from the one above, but the installation method is similar.

Note: As the above figure shown, the six holes matched with

tapping screw on the mounting plate must be used to fix the

mounting plate, the others are prepared.

2. Drill a Hole for Pipe

Decide the position of hole

for pipe according to the

location of mounting plate.

Drill a hole on the wall

about 50mm. The hole

should tilt a littledownward toward outside.

Install a sleeve through the wall hole to keep the wall

tidy and clean.

Indoor

Outdoor

Wall hole sleeve

( hard polythene tube

prepared by user)

5mm

(tilt downward)

3. Indoor Unit Pipe Installation

Put the pipes (liquid and gas pipe) and cables

through the wall hole from outside or put them

through from inside after indoor pipe and cables

connection complete so as to connect to outdoor

unit.

Decide whether saw the unloading piece off in

accordance with the pipe direction.(as shown

After connecting pipe as required, install the drain

hose. Then connect the power cords. After

connecting, wrap the pipes, cords and drain hose

together with thermal insulation materials.

7

Note: When installing the pipe

at the directions 1,2 or 4, saw

the corresponding unloading

piece off the indoor unit base.

Pipe direction

1

2

Trough

knock-down panel

Cut off the Knock-down panel

along the trough using needle

nose pliers or other suitable

tool.

below)

3

4

Pipe Joints Thermal Insulation:

Wrap the pipes joints with thermal insulation

materials and then wrap with a vinyl tape.

Thermal insulation

wrapped with vinyl type

Pipes Thermal Insulation:

a. Place the drain hose under the pipes.

b. Insulation material uses polythene

foam over 6mm in thickness.

Note: Drain hose is prepared by user.

Drain pipe should point downward

for easy drain flow. Do not arrange

the drain pipe twisted, sticking out

or wave around, do not immerse

the end of it in water.

If an extension drain hose is connected to the drain

pipe, make sure to thermal insulated when passing

along the indoor unit.

When the pipes is directed to the right, pipes, power

Cord and drain pipe should be thermal insulated and

fixed onto the back of the unit with a pipe fixer.

Small

pipe

Large pipe

Thermal insulation tube

Power cord

Drain hose

(prepared by user)

A. Insert the pipe fixer to the slot. B. Press to hook the pipe fixer

onto the base.

Base Base

Base

Pipe fixer Pipe fixer

Hook here

Insert here

drain

hose

drain

hose

large

pipe

large

pipe

small

pipe

small

pipe

(just a schematic)

Piping Connection:

If you don't hear the exhaust noise,

please contact with the merchant.

a.Before unscrewing the big and the

small sealing caps, press the small

sealing cap with the finger until the

exhaust noise stops, and then

loosen the finger.

b.Connect indoor unit pipes with

two wrenches. Pay special attention

to the allowed torque as shown

below to prevent the pipes,

connectorsand flare nuts from being

deformed and damaged.

c. Pre-tighten them with fingers at

first, then use the wrenches.

Pipe size

Model

Liquid Side ( 1/4 inch) φ6mm or

5k~12K,13k~18K,21 K~24

12K , 13K~18K

#

18K , 21K~36K

#

#

18K , 21K~36K

5K~13K

15~20N·m

17mm 0.5mm

0.6mm

0.6mm

0.6mm

0.6mm

22mm

24mm

22mm

27mm

30~35N·m

30~35N·m

50~55N·m

60~65N·m

Liquid Side ( 3/8 inch)φ9.53mm or

Gas Side ( inch)φ12mm or 1/2

Gas Side ( 3/8 inch)φ9.53mm or

Gas Side ( 5/8 inch)φ16mm or

Torque Nut width Min.thickness

1.0mm

36K# 32mm

Gas Side ( 3/4 inch)φ19mm or 70~75N·m

Note: Piping connection should be conducted on outdoor

side !

For Inverter appliance

For ON-OFF appliance

# # # #

Note: The unit of 12K ,18K ,24K ,36K is bigger than the unit of

12K,18K,24K,36K.

Pipe size

Model

Liquid Side ( 1/4 inch) φ6mm or

5 12K,13 18K,21 24K~ ~ ~

12 ,14,15,18K

#

K

#

18K ,22,24K ,28,30,36K

#

18K ,22,24,28,30,36K

#

36K#

5~10K,12K

15~20N·m

17mm 0.5mm

0.6mm

0.6mm

0.6mm

0.6mm

22mm

24mm

22mm

27mm

30~35N·m

30~35N·m

50~55N·m

60~65N·m

Liquid Side ( 3/8 inch)φ9.53mm or

Gas Side ( inch)φ12mm or 1/2

Gas Side ( 3/8 inch)φ9.53mm or

Gas Side ( 5/8 inch)φ16mm or

Torque Nut width Min.thickness

1.0mm

32mm

70~75N·m

Gas Side ( 3/4 inch)φ19mm or

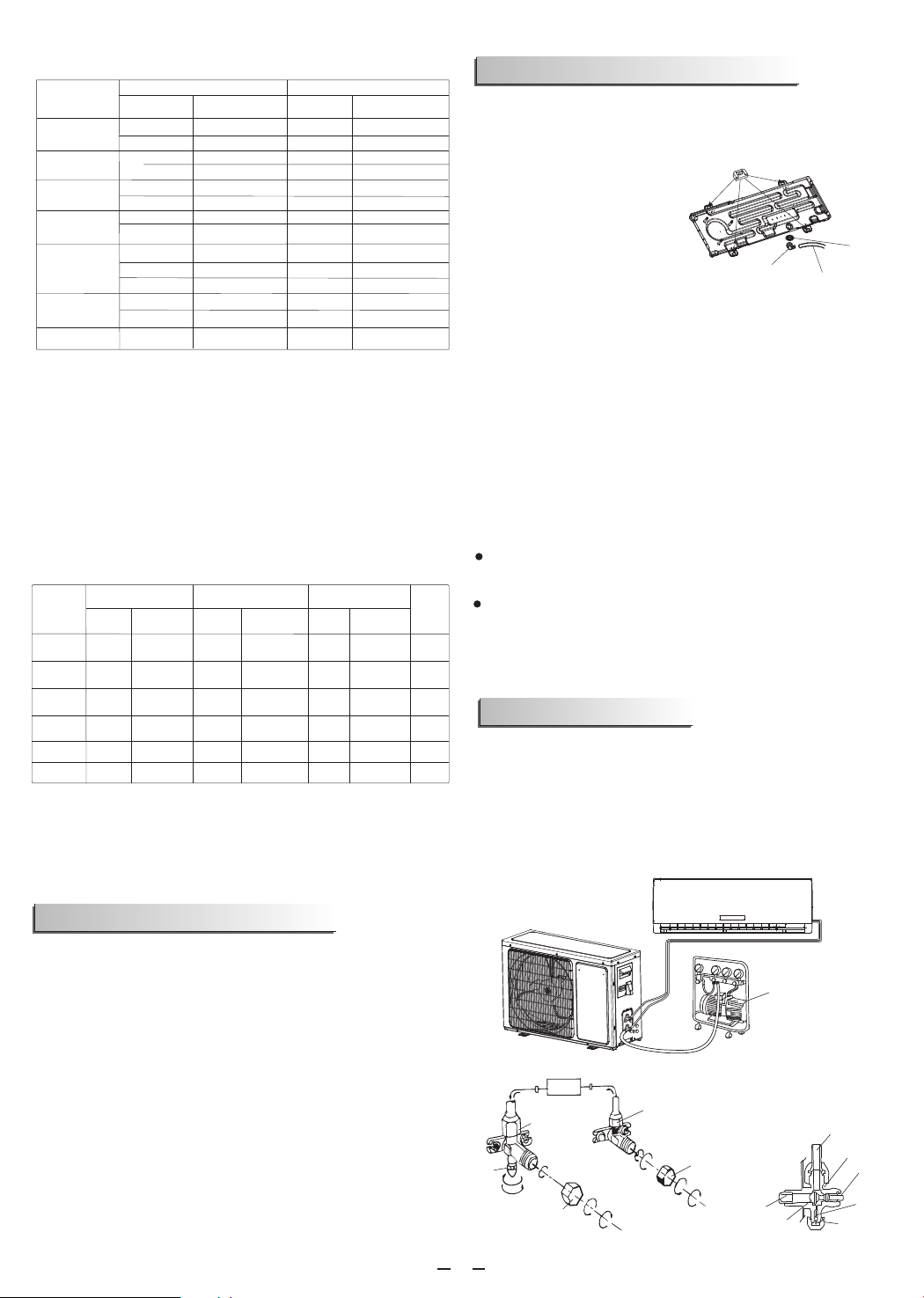

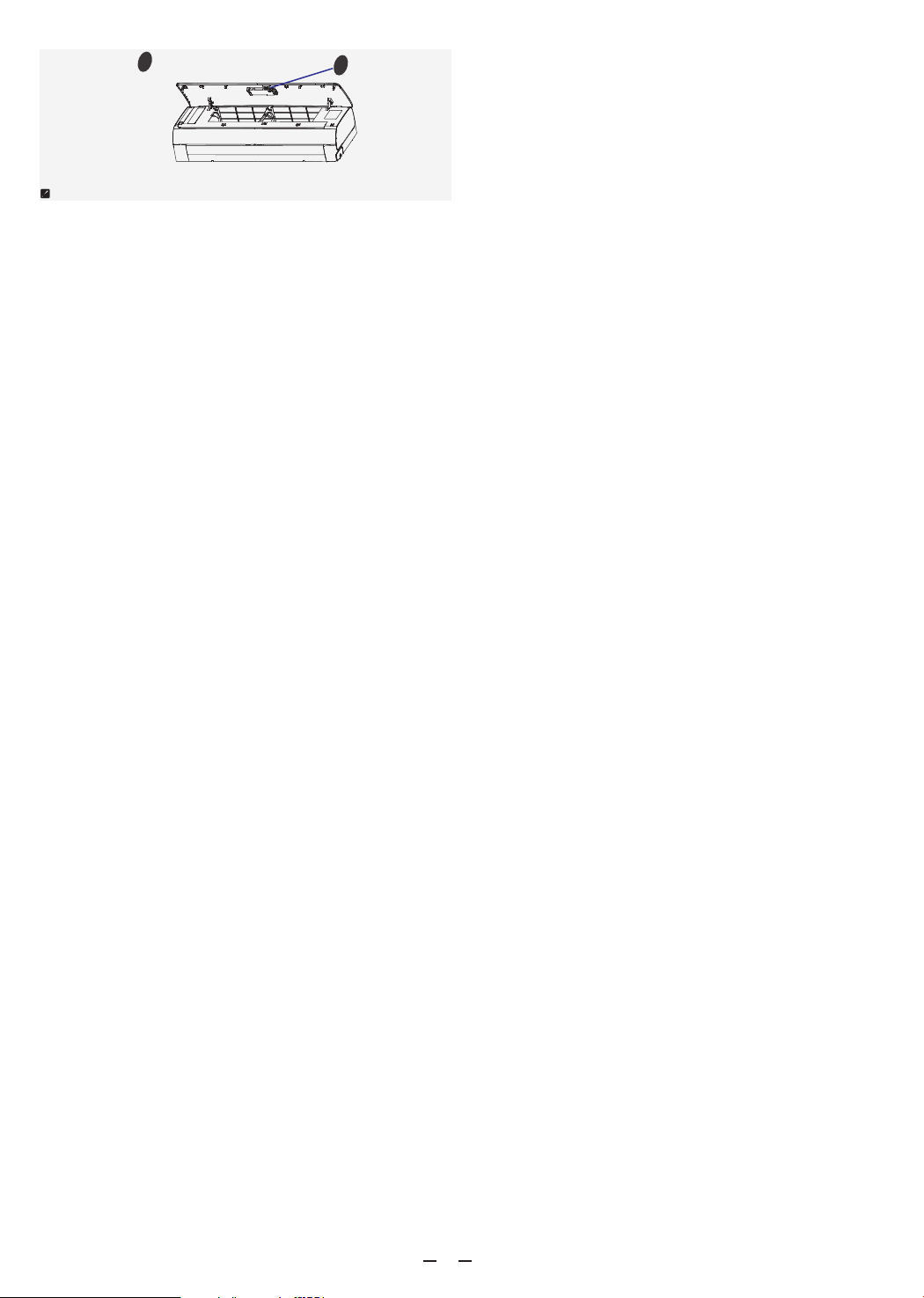

4. Connecting of the Cable

Outdoor Unit

Indoor Unit

1) Remove the access door from the unit by

loosening the screw. Connect the wires to the

terminals on the control board individually as

follows.

Connect the power cord to the indoor unit by

connecting the wires to the terminals on the control

board individuallyin accordance with the outdoor

unit connection.

2) Secure the power cord onto the control

with cable clamp.

board

.

3) Reinstall the access door to the original position

with the screw.

4) Use a recognized circuit breaker for 24K model

between the power source and the unit. A

disconnecting device to adequately disconnect all

supply lines must be fitted.

Note: For some models, it is necessary to remove the

cabinet to connect to the indoor unit terminal.

Access door

Terminal(inside)

Outdoor unit

The figures in this manual are based on the external

view of a standard model. Consequently, the shape

may differ from that of the air conditioner you have

selected.

Chassis

Cabinet

Front panel

Terminal (inside)

Indoor unit

Caution:

1. Never fail to have an individual power circuit specifically

for the air conditioner. As for the method of wiring, refer to

the circuit diagram posted on the inside of the access door.

2. Comfirm that the cable thickness is as specified in the

power source specification.

3. Check the wires and make sure that they are all tightly

fastened after cable connection.

4. Be sure to install an earth leakage circuit breaker in wet or

moist areas.

8

# # #

Note: The unit of 12K ,18K and 36K is bigger than the unit of 12K,

18K and 36K.

Attention:

The plug must be accessible even after the installation of the

appliance in case there is a need to disconnect it. If not

possible, connect appliance to a double-pole switching device

with contact separation of at least 3 mm placed in an

accessible position even after installation.

Cable Specifications for Inverter appliance

NOTE:

NOTE:

1.K* means the this model comes from indoor unit.

2.K** indicates indoor power supply unit model with power line and

plug.

3.For 14K*~18K* models under Tropical(T3) Climate condition, the

normal cross-sectionl area of Power cord and Power connecting

2

cord is 2.5mm ×4

power supply of

.

Capacity

(Btu/h)

5K~13K

H07RN-F

IS:9968

H05VV-F

IS:694

IS:694

IS:694

5K*~ K*13

Power connecting cord

Power cord

Type Type

Normal cross

- sectional area

Normal cross

- sectional area

0.75~1.5 2

mm X4

0.75~1.5 2

mm X4

0.75~1.5 X3

2

mm

2

0.75~1.5mm X3

H07RN-F

H07RN-F

H05VV-F

H05VV-F

2

2.5mm X3

2

2.5mm X3

2

1.5mm X3

2

2.5mm X4

2

2.5mm X4

2

1.5mm X4

2

1.0mm X4

H07RN-F

2

2.5mm X3

H07RN-F

2

2.5mm X3

H07RN-F

2

2.5mm X5

H07RN-F

H07RN-F

IS:9968

IS:9968

2

1.5/2.5mm X3

2

1.5/2.5mm X3

H05VV-F 2

1.5/2.5mm X4

2

1.5/2.5mm X4

21K*~30K*

21K**~24K**

21K~36K

H07RN-F H05RN-F 2

0.75mm X4

0.75~1.5 X3

2

mm

14K*~ K*18

H07RN-F 2

1.5mm X3 H07RN-F 2

1.5mm X5

H07RN-F H07RN-F 0.75~1.5 2

mm X5

0.75~1.5 X3

2

mm

14K~18K

H07RN-F 2

1.5mm X3 H05RN-F 2

0.75mm X4

2

0.75mm X4

H05RN-F

2

2.5mm X3

H07RN-F

Cable Specifications for ON-OFF appliance

2

2

The cord may be different from the list above. It may be used as

the next list. And it can be larger.0-6A, use 0.75mm or 18AWG.

0-10A, use 1mm or 16AWG. 0-16A, use 1.5mm or 14AWG 0-20A,

use 2.5mm or 14AWG. 0-25A, use 2.5mm or 12AWG. 0-32A,

use 4mm

2

2 2

22

2

Capacity

(Btu/h)

To indoor

H07RN-F

Power connecting cord

Power cord

Type Type Type

Normal cross

- sectional area

Main

power

supply

Normal cross

- sectional area

Normal cross

- sectional area

Power connecting cord1

2

2.5mm X3

To indoor

To outdoor

2

1.5~2.5mm X3

5K~13K

H05VV-F

2

0.75~1.5mm X3

H05VV-F

H05RN-F

H05RN-F

H05RN-F

2

1.5~2.5mm X3

2

0.75mm X2

(Heat-pump)

2

0.75mm X2

(Heat-pump)

2

0.75mm X3

(Heat-pump)

H07RN-F

H05RN-F

H07RN-F

2

0.75~1.0mm X3

2

1.5mm X3

2

1.0mm X3

2

1.0mm X4Cooling only

To indoor

18K~30K

2

1.5~2.5mm X3

H05VV-F 2

1.5~2.5mm X4

H07RN-F

H07RN-F 2.5~ X3

2

4.0mm

To outdoor

24K~36K

H05RN-F

H07RN-F

14K~24K

H05RN-F

2

0.75mm X2

(Heat-pump&Optional)

18K~30K

H07RN-F 1.5 X5

2

mm

To outdoor

H05RN-F 2

0.75mm X4

24K~36K

H05RN-F

2

0.75mm X2

(Heat-pump)

H05RN-F

H07RN-F 2

1.0mm X4

2

0.75mm X4

H05RN-F

2

0.75mm X2

(Heat-pump&Optional)

Wiring diagram

Warning:

Before obtaining access to terminals, all supply

circuits must be disconnected.

Make sure that the color of the wires in the outdoor

unit and terminal No. are the same as those of the

indoor unit, the details please refer to the wiring

diagram which is near the terminal inside the unit.

Outdoor unit installation

1. Install Drain Port and Drain Hose (for heat-pump

model only)

Drain hose

(prepared by user)

Washer

Drain port

Rubber pad (optional)

Place under the leg pedestal

The condensate drains

from the outdoor unit when

the unit operates in heating

mode. In order not to

disturb your neighbor and

protect the environment, install

a drain port and a drain hose to direct

the condensate water. Just install the drain port and

rubber washer to the chassis of the outdoor unit,

then connect a drain hose to the port as the right

figure demonstrates.

2. Install and Fix Outdoor Unit

Fix with bolts and nuts tightly on a flat and strong

floor. If installed on the wall or roof, make sure to fix

the supporter well to prevent it from shaking due to

serious vibration or strong wind.

3. Outdoor Unit Piping Connection

Remove the valve caps from the 2-way and 3-way

valve.

Connect the pipes to the 2-way and 3-way valves

separately according to the required torque.

4. Outdoor Unit Cable Connection (see previous

page)

Air purging

The air which contains moisture remaining in the

refrigeration cycle may cause a malfunction on the

compressor. After connecting the indoor and outdoor

units, release air and moisture from the refrigerant

cycle using a vacuum pump, as shown below.

Note: To protect the environment, be sure not to discharge

the refrigerant to the air directly.

Refrigerant flow direction 2-way valve

(6) Open 1/4 turn

valve cap

(1) Turn

(8) Tighten

(2) Turn

3-way valve

(8) Tighten

(1) Turn

(7) Turn to fully open the

valve

(7) Turn to fully open the valve

(8) Tighten

3-way valve diagram

connect to indoor unit

open position

spindle

service port cap

Service

port

Connect to outdoor unit

Valve core

needle

indoor unit

Valve cap

Vacuum pump

9

shock!

Electric

Dangerous!

(1) Unscrew and remove caps from 2 and 3-way

valves.

(2) Unscrew and remove cap from service valve.

(3) Connect vacuum pump flexible hose to the

service valve.

(4) Start vacuum pump for 10-15 minutes until

reaching a vacuum of 100Pa absolutes.

(5) With vacuum pump still running close the low

pressure knob on vacuum pump manifold. Then stop

the vacuum pump.

(6) Open 2-way valve ,1/4 turn, then close it after 10

seconds. Check tightness of all joints using liquid

soap or an electronic leak detector

(7) Turn 2 and 3-way valves stem to fully open the

valves. Disconnect the flexible vacuum pump hose.

(8) Replace and tighten all valve caps.

.

How to Purge Air Tubes:

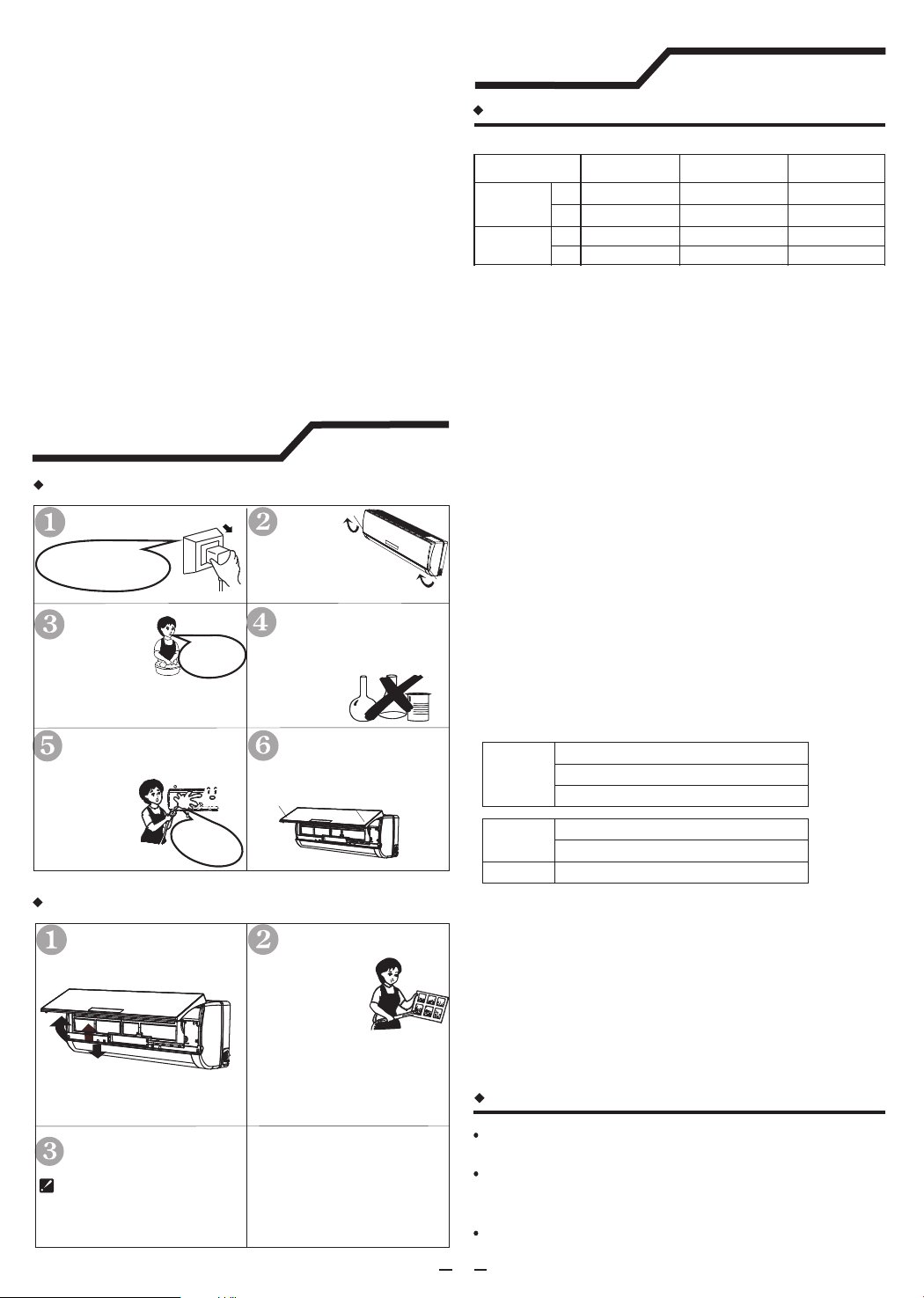

Maintenance

Front panel maintenance

Air filter maintenance

Close the front panel again

Wipe with a

soft and dry cloth.

Use soft moisture cloth to

clean if the front panel is

very dirty;

Never sprinkle water onto

the indoor unit

Clean the air filter every two weeks

if the air conditioner operates in an

extremely dusty environment.

Stop the appliance, c

the power supply and remove

the air filter.

ut off

1

2

1.Open the front panel.

2.Press the handle of the filter gently from

the front.

3.Grasp the handle and slide out the filter.

Turn off the appliance

first before disconnecting

from power supply.

Cut off the power supply

a

a

Grasp position "a"

and pull outward to

remove the front panel.

soft cloth to

clean it.

Use a dry and

Never use volatile

substance such as gasoline

or polishing powder to clean

the appliance.

Reinstall and shut the

front panel.

Reinstall and shut the front panel by

pressing position "b" downward.

bb

3

Clean and reinstall the

air filter.

If the dirt is conspicuous,

wash it with a solution of

detergent in lukewarm

water.After cleaning,

dry well in shade.

It is necessary to clean the air filter

after using it for about 100 hours.

Protection

Operating temperature for Inverter appliance

Operating condition

Temperature Cooling operation Heating operation

Indoor

temperature

max 32℃27℃

min 21℃7℃

Outdoor

temperature

max *note 24℃

min *note

*note

-15℃

Drying operation

32℃

18℃

43℃

21℃

NOTE:

*Optimum performance will be achieved within these

operating temperature. If air conditioner is used outside of

the above conditions, the protective device may trip and

stop the appliance.

*Normally,the outdoor max temperature is 43 ,but some

models will be achieved 46℃,48℃,or 50℃For Tropical (T3)

Climate condition models, the outdoor max temperature is

55 ℃.

*For some models, can keep cooling at -15 ℃ outdoor

ambient via unique design. Normally, optimum cooling

performance will be achieved above 21 ℃. Please consult

the merchant to get more information.

*For some models, can keep heating at -15 ℃ outdoor

ambient , some models heat at -20 ℃outdoor ambient, even

heat at lower outdoor ambient

The temperature of some products is allowed beyond the

range. In specific situation, please consult the merchant.

When relative humidity is above 80%, if the air conditioner

runs in COOLING or DRY mode with door or window

opened for a long time, dew may drip down from the outlet.

℃

.

The protective device maybe trip and stop the

appliance in the cases listed below

*

The temperature of some products is allowed beyond

the range. In specific situation, please consult the

merchant.

If the air conditioner runs in COOLING or DRY mode

withdoor or window opened for a long time when

relative humidity is above 80%,dew may drip down

from the outlet.

Normally,the outdoor max temperature is 43 ,but

some models will be achieved 46℃,48℃or 50℃.For

Tropical (T3) Climate condition models, the outdoor

max temperature is 55 ℃.

℃

,

NOTE:

Operating temperature for ON-OFF appliance

HEATING

o

Outdoor air temperature is over 24 C

COOLING

DRY

o

Outdoor air temperature is below -7 C

o

Room temperature is over 27 C

o

Room temperature is below 21 C

o

Room temperature is below 18 C

Noise pollution

Install the air conditioner at a place that can bear

its weight in order to operate more quietly.

Install the outdoor unit at a place where the air

discharged and the operation noise would not

annoy your neighbors.

Do not place any obstacles in front of the air outlet

of the outdoor unit lest it increases the noise level.

10

Features of protector

1. The protective device will work at following cases.

Restarting the unit at once after operation stops or

changing mode during operation, you need to wait

for 3 minutes.

Connect to power supply and turn on the unit at

once, it may start 20 seconds later.

2. If all operation has stopped, press ON/OFF

button again to restart, Timer should be set again

if it has been canceled.

Features of HEATING mode

Preheat

At the beginning of the HEATING operation, the

airflow from the indoor unit is discharged 2-5 minutes

later.

In HEATING operation the appliance will defrost

(de-ice) automatically to raise efficiency.

This procedure usually lasts 2-10 minutes. During

defrosting, fans stop operation.

After defrosting completes, it returns to HEATING

mode automatically.

Note: Heating is NOT available for cooling only

air conditioner models.

Defrost

Troubleshooting

The following cases may not always be a

malfunction, please check it before asking for

service.

Trouble Analysis

Trouble Analysis

Does not run 1. If the protector trip or fuse is blown.

2. Please wait for 3 minutes and start

again, protector device may be

preventing unit to work.

3. If batteries in the remote controller

exhausted.

4. If the plug is not properly plugged.

No cooling or heating air 1. Is the air filter dirty

2. Are the intakes and outlets of the air

conditioner blocked?

3. Is the temperature set properly?

?

Ineffective control If strong interference(from excessive

static electricity discharge, power

supply voltage abnormality)presents,

operation will be abnormal. At this time,

disconnect from the power supply and

connect back 2-3 seconds later.

Does not operate

immediately

don't run

Changing mode during operation,

3 minutes will delay.

Peculiar odor This odor may come from another

source such as furniture, cigarette etc,

which issucked in the unit and blows

out with the air.

A sound of flowing water Caused by the flow of refrigerant in the

air conditioner, not a trouble.

Defrosting sound in heating mode.

Cracking sound is heard The sound may be generated by the

expansion or contraction of the front

panel due to change of temperature.

Spray mist from the outlet Mist appears when the room air

becomes very cold because of cool air

discharged from indoor unit during

COOLING or DRY operation mode.

The compressor indicator

(red) lights on constantly,

and indoor fan stops.

The unit is shifting from heating mode

to defrost.The indicator will lights off

within ten minutes andreturns to

heating mode.

The symbols may be different from these models, but the functions are similar.

Example:

81

2

34

Display introduction

NO

Display

Introduction

7

9

11

12

13

14

1

5

8

6

3

4

10

2

Temperature indicator

Display set temperature.

It shows FC after 200 hours of usage as

reminder to clean the filter.After filter cleaning

press the filter reset button located on the

indoor unit behind the front panel in order to

reset the display.(optional)

Running indicator

It lights up when the AC is running.

It flashes during defrosting.

Timer indicator

It lights up during set time.

Sleep indicator

It lights up in sleep mode

Compressor indicator

It lights up when the compressor is on

Mode indicator

Heating displays orange,others display white

Fan speed indicator

Smart WIFI indicator

It lights up during WIFI is on

NANOE indicator

It lights up in NANOE mode.

FAN ONLY mode indicator

It lights up in FAN ONLY mode

Airflow Follow You/Airflow Avoid You

indicator

Humidity indicator

It lights up in humidity mode.

Artificial Intelligence Smart Running

Indicator

It lights up in AI mode

Signal Receptor

AI

1 2 3 4 5 8

11

Emergency button

A

Pressing this button can let the AC run or stop.

A

The symbol may be different from your model, but the button is similar.

12

1

Table des matières

2

6

6

7

11

7

10

10

11

1

Mode d’emploi de la télécommande. Voir la rubrique « Mode d’emploi

de la télécommande »

8

9

9

9

Consignes de sécurité

Préparation pré-installation

Précautions de sécurité

Consignes d’installation

Schéma d’installation

Choisissezl’emplacement de votre appareil

Installation de l’unité intérieure

Raccordement du câble

Schéma de câblage

Installation de l’unité extérieure

Purge de l'air

Entretien

Protection

Dépannage

Présentation de l’affichage

Consignes de sécurité

Préparation pré-installation

1. Afin de garantir un fonctionnement normal de votre

appareil,veuillez lire attentivement ce manuel avant toute

installation et veuillez respecter les consignes qui y sont

livrées.

2.Ne laissez pas l’air pénétrer dans le système réfrigérant

ou d’évacuation lorsque vous déplacez le climatiseur.

3. Vérifiez bien la connexion au sol de votre appareil.

4. Vérifiez les câbles de raccordement ainsi que les

conduits et assurez-vous qu’ils sont tous bien fixes avant

de mettre le climatiseur en marche.

5. Le système est doté d’un bouton d’arrêt d’urgence.

6. Après l’installation, l’utilisateur doit faire fonctionner

l’appareil conformément aux consignes livrées dans le

manuel d’utilisation, stocker, entretenir et déplacer le

climatiseur comme cela est indiqué.

7. Fusible de l’unité intérieure T3.15A 250VAC or T5A

250VAC. Veuillez-vous reporter à l’information sur la carte

de circuit pour les paramètres corrects, qui doivent être

cohérents avec l’information sur la carte.

8. Pour les modèles 5K~13K, fusible de la partie extérieure

de l’appareil: T15A 250VAC or T20A 250VAC. Veuillez

vous référer à la sérigraphie sur la carte de circuit imprimé

pour les paramètres réels, qui doivent être cohérents avec

les paramètres sur la sérigraphie.

9. Pour les modèles 14K~18K, fusible de la partie

extérieure de l’appareil: T 20A 250VAC.

10. Pour les modèles 21K~36K, fusible de la partie

extérieure de l’appareil :T 30A 250VAC.

11. Les consignes d’installation livrées avec cet appareil

permettent de garantir un câblage correct, et pour éviter

les risques de fuites électriques (tension à respecter: 10

mA). Vérifiez bien qu’un dispositif de courant résiduel

(DCR) est installé (sur votre réseau et ne dépasse pas 30

mA).

12. Attention: risque d’électrocution pouvant entraîner des

blessures graves, voire la mort: Débranchez les sources

d’alimentation extérieures avant toute opération e

dépannage.

13. La longueur maximale du raccordement entre l’unité

intérieure et l’unité extérieure doit être inférieure à 5

mètres. Une longueur supérieure pourrait endommager le

fonctionnement du système.

14. Cet appareil n’est pas conçu pour être utilisé par des

personnes (y compris les enfants) ayant des capacités

physiques, sensorielles ou mentales réduites, ou ne

disposant pas d’une expérience et des connaissances

adéquates, à moins d’être supervisé ou instruit par une

personne responsable de leur sécurité. Les enfants doivent

être surveillés par un adulte qui doit s’assurer qu’ils ne

jouent pas avec l’appareil.

15. Cet appareil peut être utilisé par des enfants âgés de 8

ans et plus, ainsi que par des personnes dont les capacités

mentales, sensorielles et physiques sont réduites, si elles

ont appris à l’utiliser ou si elles sont placées sous la

surveillanced’une personne responsable. Les enfants ne

doivent pas jouer avec l’appareil. Le nettoyage et

l'entretien par l'utilisateur ne doivent pas être effectués par

des enfants sans surveillance.

16. Les piles de la télécommande doivent êtrerecyclées ou

mises au rebut selon les normes en vigueur. Mise au rebut

des piles usagées --- Merci de vous débarrasser de ces

piles dans la déchetterie la plus proche ou de faire appel

aux autorités compétentes.

17. Si l'appareil utilise un câblage fixe, il doit être équipé

de systèmes de déconnex du réseau d'alimentation, au

moyen d’un système de séparation de contact sur tous les

pôles, afin de permettre une coupure en cas de

problèmes de surtension de catégorie III.

18. Ces systèmes doivent être installés conformément aux

règlementations en vigueur.Si le cordon d'alimentation est

endommagé, il doit être remplacé par le fabricant, son

agent de service ou un technicien qualifié afin d'éviter tout

danger potentiel.

19. L'appareil doit être installé conformément aux

règlementations en matière de câblage.

20. L'entretien ne doit être effectué que selon les

recommandations du fabricant de l'équipement. La

maintenance et les réparations nécessitant l'assistance

d'un autre personnel qualifié doivent être effectuées sous

la supervision de la personne compétente pour l'utilisation

des réfrigérants inflammables.

21. L'appareil ne doit pas être installé dans une buanderie.

22. En ce qui concerne l’installation, veuillez-vous référer

au chapitre « Instructions d’installation ».

23. En ce qui concerne l’entretien, veuillez-vous référer au

chapitre « Entretien ».

24. Pour des modèles utilisant du réfrigérant R32,a

connexion l des tuyaux devrait être effectuée du côté

extérieur.

Remarque

1. Lorsque vous approvisionnez le système en liquide

frigorigène, vérifiez bien que ce dernier est complètement

liquide, surtout s'il s'agit d'un liquide catégorie R32.

Autrement, la composition chimique du liquide (R32) peut

varier et cela peut affecter la performance du climatiseur.

2. Selon le type de liquide frigorigène utilisé (R32, la valeur

GWP est égale à 675), la pression du tube est très élevé;

soyez donc attentif lorsque vous installez et réparez

l'appareil.

3. Si le cordon d'alimentation est endommagé, il doit être

remplacé par le fabricant, l'un de ses agents ou toute autre

personne qualifiée, afin d'écarter tout risque.

4. L'installation de cet appareil doit être prise en charge par

une personne qualifiée et expérimentée, conformément aux

consignes livrées dans cette notice.

5. La température à l'intérieur du circuit frigorigène sera

élevée; merci de maintenir le câble de raccordement à

l'écart du tube en cuivre.

Pré-réglages

Avant d'utiliser le climatiseur, vérifiez bien les pré-réglages

suivants.

1.Pré-réglage à distance

Dès que de nouvelles piles sont installées dans la

télécommande, cette dernière passe automatiquement en

mode « préchauffage de la pompe » par défaut. Dans le

cas où le climatiseur que vous avez acheté ne soit pas un

modèle réversible, une télécommande spéciale pour la

pompe à chaleur peut être utilisée.

11

2. Rétroéclairage de la télécommande (optionnel)

Maintenez n'importe quelle touche de la télécommande

enfoncée pour activer le rétroéclairage. Ce dernier se

désactive automatiquement après 10 secondes.

Remarque: Le rétroéclairage est une fonction

disponible en option.

3. Pré-réglage du redémarrage automatique

Le climatiseur est doté d'une fonction de redémarrage

automatique.

Préservation de l'environnement

Cet appareil est constitué de matériaux recyclables et

réutilisables. Son élimination doit se faire conformément aux

normes en vigueur. Avant de vous en débarrasser, pensez

à bien sectionner le cordon d'alimentation ainsi que les

conduites, de façon à ce qu'il ne puisse pas être réutilisé.

Pour plus d'informations à propos de recyclage et de

l'élimination de cet appareil, contactez la boutique auprès de

laquelle vous avez acheté cet appareil, ou les Autorités / le

Centre de Tri les plus proches.

ELIMINATION DE L'APPAREIL

Cet appareil est protégé par la Directive

Européenne 2012/19/CE relative à

l'élimination des déchets

électroniques (WEEE).

Cette directive indique que cet appareil ne

peut pas être éliminé avec les autres déchets

domestiques. Afin d'éviter tout risque pour

l'environnement et la santé humaine, recyclez

cet appareil de façon responsable et

écologique, afin de favoriser la réutilisation

des ressources matérielle. Pour éliminer votre appareil,

transférez-le vers un centre de tri ou contactez la boutique

auprès de laquelle vous l'avez a cheté. Ces derniers

pourront prendre en charge son élimination.

Précautions de sécurité

Les symboles contenus dans le manuel

d’utilisation sont expliqués à la suite.

A éviter absolument.

Situation à risques.

Connexion au sol obligatoire.

Attention: une mauvaise manipulation peut entraîner

une blessure grave, voire la mort.

N’utilisez pas le disjoncteur

et ne débranchez pas la

prise pendant que le

climatiseur est en marche.

Cela pourrait entraîner un

risque d’incendie.

OFF

ON

Il est de la responsabilité

de l’utilisateur de veiller à

ce que l’appareil soit relié

au sol conformément aux

règlementations électriques

en vigueur.

Ne touchez pas les

boutons d’utilisation

avec les mains

mouillées.

Eteignez l’appareil au

moyen de la

télécommande avant

de couper le courant,

en cas de

dysfonctionnement.

ON

OFF

MODE

SMART

QUIET DIMMER

ECONOMY

FEEL

FAN SPEED

CLOCK

TIMER ON

TIMER OFF

SLEEP

TEMP.

TEMP.

SUPER

Utilisez une source

d’alimentation adaptée,

conformément aux

caractéristiques indiquées

sur la plaque nominative de

l’appareil; Autrement, un

risque d’électrocution,

d’incendie ou de panne

définitive peut surgir.

Vérifiez bien que le

disjoncteur ou la prise ne

sont pas poussiéreux. Reliez

le cordon d’alimentation

fermement à sa prise, car un

faux contact pourrait

provoquer un incendie ou

une électrocution.

OFF

ON

Il est dangereux pour la

santé de garder le

climatiseur en marche

pendant un long moment si

vous êtes présent.Il est

conseillé de laisser le flux

d’air se diffuser dans toute

la pièce.

Empêchez le flux d’air

d’atteindre les plaques de

cuisson à gaz.

N’insérez jamais d’objets dans

l’appareil.Le ventilateur tournant

à grande vitesse, cela peut

causer des blessures.

Ne réparez pas l’appareil vous-

même.Si cette action est

effectuée incorrectement, cela

peut entraîner une électrocution,

etc.

N’insérez aucun objet dans la

partie extérieure de l’appareil.

Ne modifiez pas, n’étirez pas et

n’exercez aucune pression sur

le cordon d’alimentation, au

risque de le faire céder. Une

électrocution ou un incendie

peut être produit par un cordon

fissuré.

2

Précautions de sécurité

1. Transport d'équipements contenant des liquides

frigorigènes inflammables

Conformité avec les Règlementations en termes de

transport

2. Marquage de l'équipement au moyen de la signalétique

3. Élimination des équipements contenant du liquide

frigorigène inflammable

4. Stockage de l'équipement/dispositif

Le stockage de l'équipement doit se faire conformément

aux consignes livrées par le fabricant.

5.Stockage d'équipements emballés (non vendus)

Le stockage d'équipements encore emballés doit se

faire de façon à ce qu'aucune fuite de liquide

frigorigène ne soit rendue possible à l'intérieur de

l'emballage.

Le nombre maximum d'appareils pouvant être stockés

ensemble est fixé par les Autorités locales.

6. Informations relatives au dépannage du système

6-1 Vérifications de la zone

6-2 Procédure de travail

Les travaux doivent suivre la procédure règlementée

en vigueur, de façon à réduire les risques

d'évaporation des gaz/vapeurs inflammables présents

pendant les opérations.

Précautions liées à l'utilisation de liquide frigorigène R32

Les procédures de base d’installation sont les mêmes que

celles du réfrigérant conventionnel (R22 ou R410A).

Cependant, faites attention aux points suivants:

Conformité avec les Règlementations locales

Conformité avec les Règlementations nationales.

Avant de commencer à travailler sur un appareil

contenant un liquide frigorigène inflammable, quelques

contrôles de sécurité sont nécessaires, afin de s'assurer

que le risque d'inflammation est diminué. Pour toute

réparation du système frigorigène, les précautions

suivantes doivent être prises.

6-3 Zone de travail

L'ensemble des équipes de travail doit être informé du

type d'opérations menés à bien sur le site. Le travail dans

des zones confinées doit être évité.

Les opérations en cours autour de l'espace de travail

doivent être mises en pause. Vérifiez que l'ensemble des

conditions nécessaires à la sécurité du lieu de travail ont

été bien respectées.

6-4 Contrôle de la présence ou de l'absence de

liquide frigorigène

La zone de travail doit être équipée d'un détecteur de

fumées adapté avant le début des travaux, afin de

garantir la sécurisation de l'espace de travail.

Vérifiez que le système de détection utilisé est adapté

à une utilisation dans une atmosphère contenant des

substances inflammables (ex: système hermétique,

scellé ou intrinsèquement sûr).

6-5 Présence d'un extincteur

Dans le cas où des travaux impliquant des opérations

de chauffe seraient impliqués, la zone de travail doit être

munie d'un extincteur adapté

Un extincteur à poudre sèche ou CO2 doit être installé

dans la zone de travail.

6-6 Aucune source d'inflammation

Aucune personne chargée d'effectuer des travaux

sur un système de réfrigération impliquant un risque

d'explosion (ou contenant du liquide frigorigène) n'est

autorisée à utiliser des sources d'inflammation; car

cela pourrait entraîner un risque d'incendie ou

d'explosion.

Toute source d'inflammation possible, y compris les

allume-cigares, doit être tenue à l'écart du site

d'installation, de réparation, de retrait d'élimination,

dès qu'une fuite de liquide frigorigène est possible.

Avant de commencer les travaux, la zone de travail

doit être contrôlée, afin de s'assurer qu'aucune

source d'inflammation n'est présente. Des panneaux

« Interdiction de fumer » doivent être en place.

6-7 Zone ventilée

Vérifiez que la zone est correctement ventilée avant

de procéder à des opérations de chauffe.

Un niveau de ventilation suffisant doit être assuré

pendant les opérations.

La ventilation doit permettre la dissipation du liquide

de réfrigération et doit, de préférence, permettre son

évacuation vers l'extérieur.

Lorsque vous remplacez des composants électriques,

ces derniers doivent être installés conformément aux

caractéristiques indiquées.

Les consignes de maintenance et de réparation

doivent toujours être observées. Encas de doute,

contacter l'Assistance Technique du fabricant.

Les vérifications suivantes doivent être effectuées sur

les modèles contenant du liquide frigorigène:

6-8 Contrôle de l'équipement de réfrigération

–La taille de la charge est conforme à la taille de la

pièce dans laquelle les pièces contenant le

réfrigérant sont installées;

Les appareils de ventilation et les sorties

fonctionnent correctement et ne sont pas

obstrués;

Dans le cas où un circuit frigorigène indirect serait

utilisé, le circuit secondaire devra être vérifié afin

de s'assurer de la présence de liquide frigorigène;

Le marquage sur l'équipement reste visible et

lisible. Les marques et signes illisibles doivent

être corrigés;

Les conduites ou les tuyaux de réfrigération sont

installés de façon à n'être exposés à aucune

substance susceptible de corroder les

composants contenant le liquide frigorigène, sauf

dans le cas où ces composants seraient

constitués de matériaux protégés/résistants à de

telles substances.

–

–

–

–

6-9 Vérifications des appareils électriques

Les opérations de maintenance et de réparation

apportées aux composants électriques doivent

inclure des contrôles de sécurité de base ainsi que

des procédures d'inspection spécifiques aux

composants.

Si une erreur est constatée, susceptible de mettre en

danger l'utilisateur, alors le circuit ne doit pas être

alimenté en électricité jusqu'à résolution de la panne.

Dans le cas où le problème ne pourrait pas être résolu

dans l'immédiat, mais que l'appareil doivent continuer

de fonctionner, une solution temporaire devra être

mise en place.

Ce problème devra être signalé au propriétaire de

l'équipement, de façon à ce que les différentes parties

en soient informées.

Les contrôles de sécurité de base incluent les

vérifications suivantes:

–Que les condensateurs soient déchargés: Cette

opération doit avoir lieu de manière sécurisée, afin

d'éviter les risques d'étincelles;

–Existe-t-il des composants électriques et/ou des

câbles exposés pendant les opérations

d'approvisionnement en liquide, de réparation ou de

vidange;

–Qu'il y a continuité de la liaison à la terre.

7. Réparation des composants scellés

Pendant les opérations de réparation et avant le

retrait des caches des composants hermétiques,

l'ensemble des dispositifs électriques doit être

déconnecté de l'appareil en cours de réparation.

Il est absolument nécessaire de disposer d'une

alimentation électrique pendant les opérations de

dépannage, ainsi que d'un système de détection des

fuites, dès qu'un risque de situation dangereuse

existe.

Une attention particulière doit être accordée aux

éléments suivants pour garantir qu'en travaillant sur

les composants électriques, le boîtier ne soit pas

modifié de manière à affecter le niveau de protection.

3

Cela comprend la vérification des câbles, des

raccords, des bornes, embouts d'étanchéité, etc. Il

convient de vérifier qu'ils ne sont pas endommagés.

Vérifiez que l'appareil est assemblé de manière

sécurisée.

Vérifiez que les joints et autres composants

hermétiques n'ont pas été endommagés, de façon à

ce qu'ils soient toujours en mesure de protéger

l'appareil d'une éventuelle inflammation.

Les pièces de rechange doivent être utilisées selon