KELE • www.kele.com • FAX 800-284-5353 USA 888-397-5353 • International 901-382-6084

DUCT SMOKE DETECTOR

SL-2000 SERIES

DESCRIPTION

The SL-2000 Series Duct Smoke Detectors provide

early detection of smoke and combustion products pre-

sent in air moving through HVAC ducts. Air sampling is

accomplished by intake sampling tubes, which are

ordered separately. A standard length exhaust tube is

provided with each detector. These devices are designed

to prevent the recirculation of smoke in areas by the air

handling systems, fans, and blowers. Complete systems

may be shut down in the event of smoke detection.

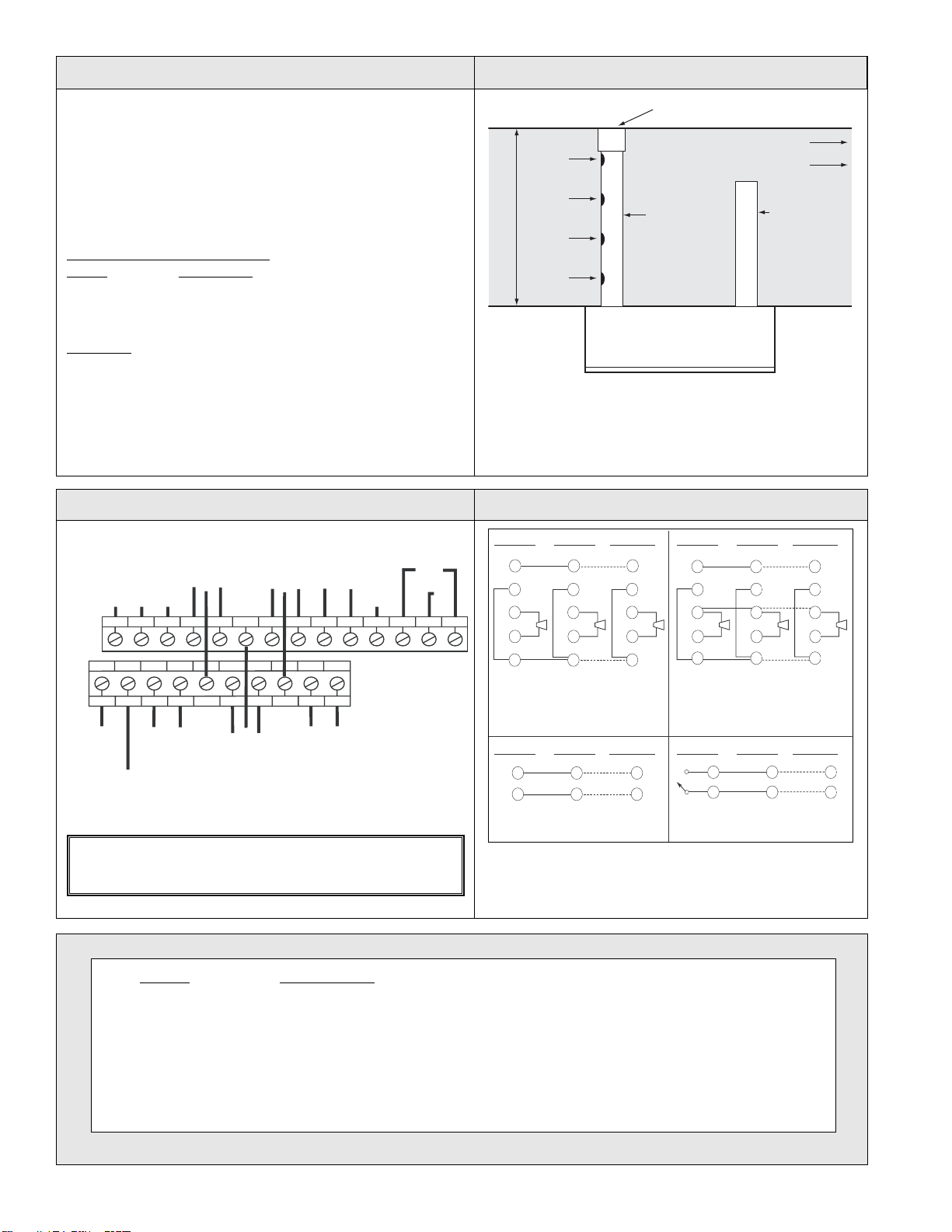

OPERATION

The SL-2000 Series is designed to operate in duct

widths from 12.0" to 10.0' (30.5 cm to 3.05m) with an air

velocity from 100-4000 fpm (0.5-20.3 mps). The

SL-2000 Series will operate on any one of four input

voltages: 24 VAC, 24 VDC, 115 VAC, or 230 VAC. It

uses either a photoelectric or ionization smoke detector

head. Each detector contains two Form C and one Form

A alarm contact, which transfer in the event of smoke.

There is also one trouble contact, which supervises the

presence of input power and removal of the detector

head. A manual test/reset switch and visual indicators of

pilot and alarm are provided on the front of the detector.

Up to 30 SL-2000 Series units may be wired to use a

common test/reset function and to alarm simultaneously

when a single unit alarms.

Power requirements

50/60 Hz (without

accessories) 24 VAC @ 55 mA standby,

190 mA alarm

24 VDC @ 15 mA standby,

70 mA alarm

115 VAC @ 16 mA standby,

32 mA alarm

230 VAC @ 10 mA standby,

20 mA alarm

Relay contact rating

Alarm (2) SPDT, 10A, 115 VAC, resistive

Alarm (1) SPST-NO, 2A, 115 VAC,

resistive

Trouble (1) SPDT, 10A, 115 VAC, resistive

Radioactive element For SL-2000-N only

Americium 241, 0.9 µCi

Air velocity 100-4000 fpm (0.5-20.3 mps)

Approvals

UL 268A; UROX.S2829

CSFM 3240-1004:105

MEA 73-92-E, Vol. 27

Ambient temp

SL-2000-N 32° to 155°F (0° to 68°C)

SL-2000-P 32° to 100°F (0° to 38°C)

Humidity 10% to 85% RH noncondensing

Material Gray plastic back box,

clear plastic cover

Weight 2.5 lb (1.13 kg)

Mounting 7" (17.8 cm) exhaust tube, sampling

tube end cap, mounting template

and hardware supplied

Dimensions 13.5"L x 4.5"H x 2.25"D

(34.3 x 11.4 x 5.7 cm)

FEATURES

• Low flow technology, 100-4000 fpm

• Universal voltage: 24 VAC, 24 VDC, 115 VAC, or

230 VAC

• Two Form C and one Form A alarm contacts and

one trouble contact

• Interchangeable "plug-in" photoelectric or ioniza-

tion heads

• Compatible with building automation and fire

alarm systems

• Dust filtering included in detector head

• Interconnect up to 30 detectors for common

functions

• Compatible with MS Series Remote Accessories

• Cover removal trouble indication

• Magnet test capability

• Front or rear loading sampling tubes

• Optional weatherproof enclosure

SPECIFICATIONS

SL-2000

April 2004