Table of Contents

MOTORISED MACHINES

Important to bear in mind when using motorised machines:

• Fumes contain toxic substances, so never use the machine in poorly ventilated spaces. Do

not run the engine in an enclosed space, as the exhaust fumes contain carbon monoxide,

which is lethal if inhaled. The motorised machine must not be used indoors.

• Risk of burns from touching hot surfaces such as exhaust pipes.

• Operate a new machine at low speed for the rst 20 hours, not at high speed and with

a full load.

• Avoid getting petrol/oil on your skin. If this happens, rinse thoroughly with water.

• Avoid breathing in petrol fumes while refuelling. Screw the tank cap on securely.

• Do not keep fuel or other explosive substances near the work zone when using

the machine.

• Only store fuel in containers intended for this purpose.

• Refuelling is not permitted indoors or when the engine is running.

• Never use dirty oil or fuel. This can cause serious damage to the engine.

• Never leave the machine with the engine running.Turn o the engine when you leave the

equipment, even for a short period.

• Only the operator may be present in the vicinity of the machine while it is in operation.

Take care if there are children in the area where the product is stored or used.

• Check that the work area is free from bystanders and objects before starting.

• Do not use the machine without having all guards correctly mounted.

• Do not operate the machine if it is vibrating substantially; stop the machine immediately

and check the maintenance schedule. Check that all nuts and bolts are tightened.

• Do not alter the engine settings unless specied by the engine manufacturer.The engine's

rpm must never exceed the value indicated on the sign.

• Never exceed the maximum driving speed.

• The SMV sign must be clearly visible during work.

• Lights must be used for driving on public roads, both in daylight and in darkness.

• Do not spray water directly on the sound damper, exhaust system or lter. Water may

creep into the engine and cause serious damage.

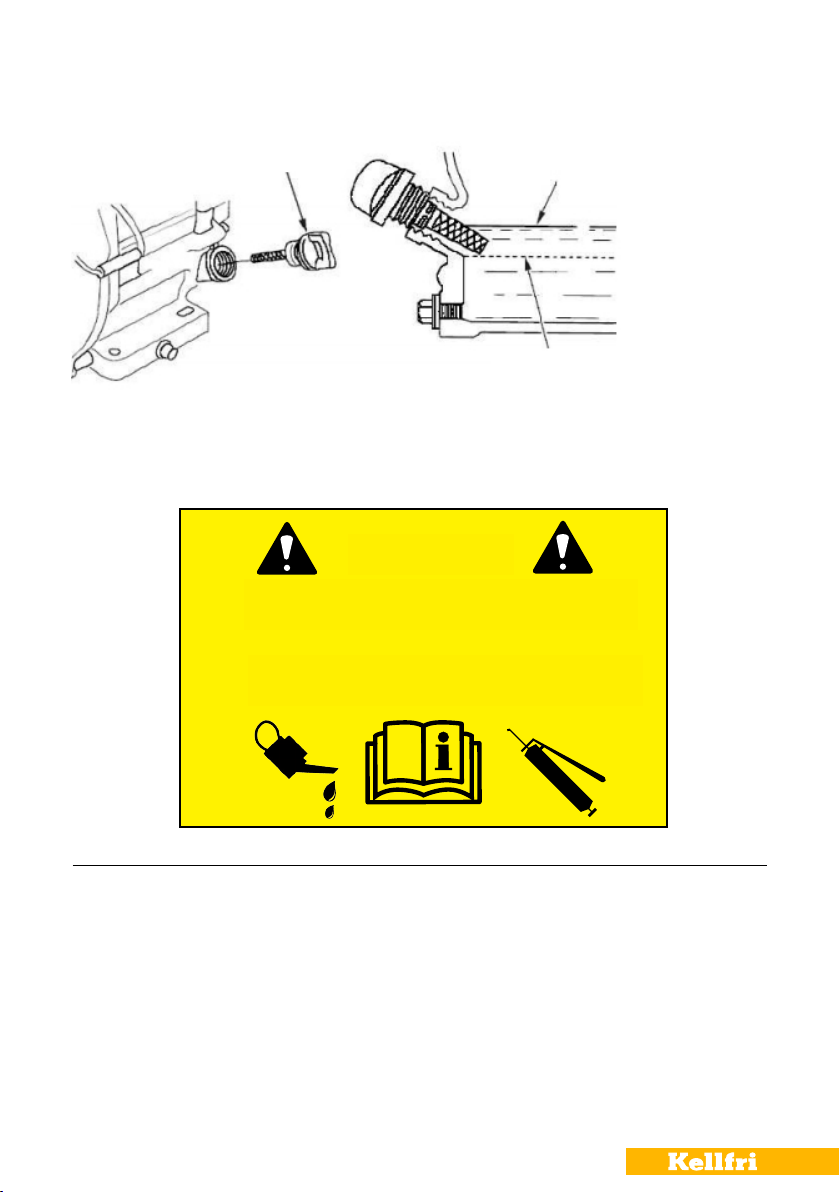

• Carry out maintenance, service and checks in line with recommendations. Replace

damaged and worn parts. Before beginning servicing work: stop the engine, remove the

key, put the gear into neutral, apply the handbrake and ensure that all parts have stopped

and cooled down.

• The exhaust pipe becomes hot and there is a risk of re if grass and dry material collect

around the exhaust pipe. Check and clean if necessary.

• A type ABE2 or 3 re extinguisher should always be easily accessible during work. Contact

your insurance provider.

Avoid hearing damage

Long-term exposure to noise can cause permanent hearing damage.

Use ear defenders.

Prevent inhalation of toxic gases

Fumes contain toxic substances, so never use the machine in poorly ventilated

spaces. Not for indoor use.

Avoid burns

Never touch the silencer or other part of the exhaust system while the generator

is running or when the parts are still hot.