PRODUCT SAFETY INFORMATION

The user of the machine should understand the contents of this manual before use, service

and installation of the equipment to the tractor and all other relevant measures. Never wear

jewelry, loose clothing, ties, scarves, belts, unbuttoned jackets that can get caught in moving

parts.

Always wear approved clothing that complies with the provisions of accident prevention

purposes, such as non-slip shoes, hearing protection, goggles and gloves. Wear a jacket with

reective stickers on the equipment used near public roads.

Contact your dealer, health authority or the nearest equivalent authority for information about

the current safety regulations and special provisions to guarantee personal safety.

DANGER!

ALWAYS DISENGAGE THE PTO shaft, TURN OFF THE TRACTOR ENGINE AND

APPLY THE PARKING BRAKE BEFORE ADJUSTMENT IS PERFORMED ON THE

MACHINE

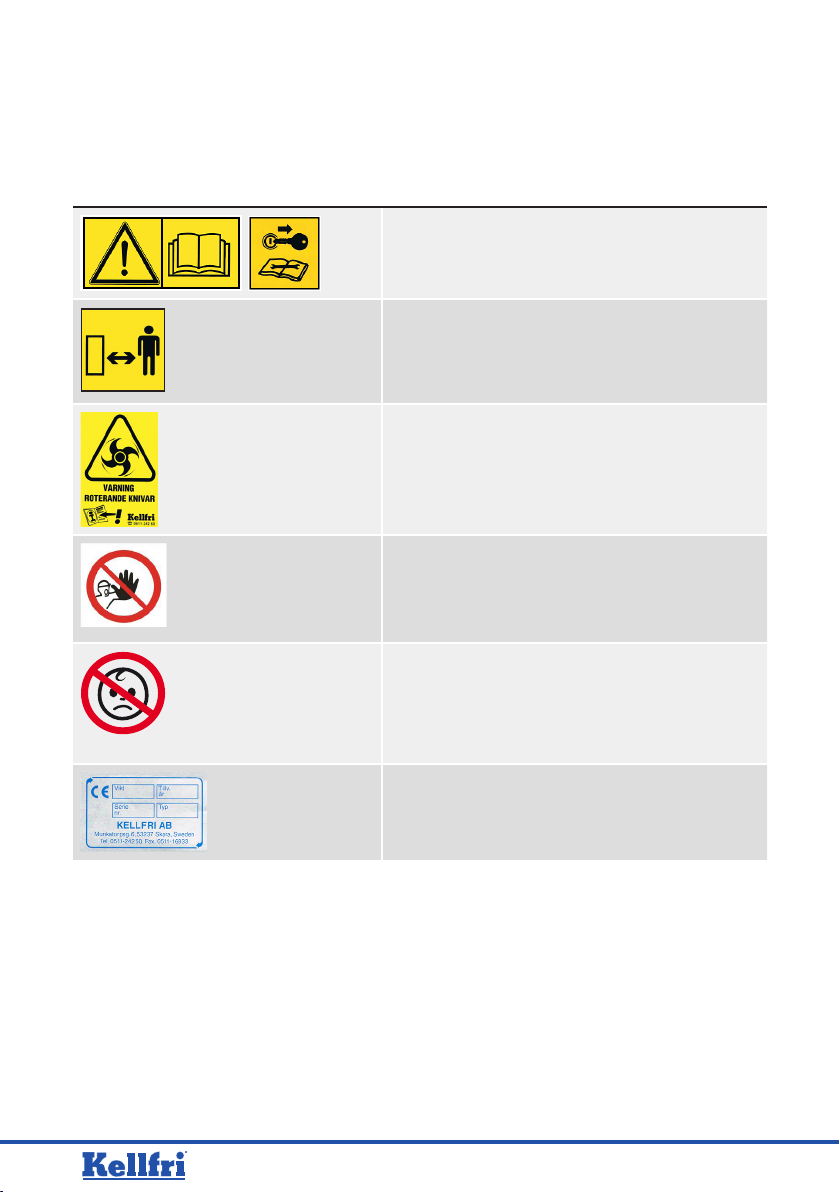

Warning!

Never stick your hands or feet under the machine without stopping the

equipment and the tractor engine.The rotors may continue to rotate for up to

1 minute after the PTO shaft have been disconnected

• Never leave the equipment with the tractor engine running. Turn o the engine and

apply the parking brake when you leave the equipment, even for a short while.

• Never leave the equipment uplifted because the hydraulics can lose pressure and

the equipment can fall down.

• Make sure that all guards are tted correctly and cannot come loose.

• PTO shaft must be protected throughout its entire length. Make sure to anchor the

safety chain well.

• Only you driving the tractor must be in the vicinity of the machine during work.

Make sure no one stands under suspended load.

• Check before driving that no rocks sticking up on the eld, or lying objects that can

be thrown during operation.

• Never stick your hands or feet under the machine without rst stopping the

equipment and the tractor engine.

• Always disengage the machine before performing service or maintenance work.

• Do not try to remove things that get stuck during operation. Ensure that the engine

has stopped and the blades have stopped spinning before any action is taken on

the machine.

• Do not drive with the mower if excessive vibration occurs, stop the machine

immediately, check and rectify any faults before re using the machine.

• Do not climb on the mower! NEVER allow anyone to ride on the machine!

• It is forbidden to stand between the tractor / loader and the machine during

connection and disconnection