Page 2 of 14

RCA2610 Series Installation/Operation Guide

Rev D

KELLY MANUFACTURING COMPANY

KMC

KMC Publication No.1401-3

SECTION 1: INSTRUMENT DESCRIPTION

1.1 GENERAL DESCRIPTION

Anattitudeindicator,alsoknownasagyrohorizonorarticialhorizon,isaninstrumentusedinanaircrafttoinformthepilotofthe

orientation of the airplane relative to the earth. It indicates pitch (fore and aft tilt) and bank (side to side tilt), and is a primary instru-

mentforightininstrumentmeteorologicalconditions.Attitudeindicatorsalsohavesignicantapplicationsundervisualightrules.

The RCA2610 Digital Electronic Attitude Indicator receives digital information from a series of accelerometers which is processed

to actuate a display that has two dimensions of freedom, simultaneously displaying pitch and bank. The display is colored to

indicate the horizon as the division between the two colored segments (blue for sky and brown for ground), and is intended to be

intuitive to use.

Because the RCA2610 has no mechanical gyroscope, it is much more stable than traditional horizons. The unit is designed to

work in 360 degrees of pitch and roll and, unlike a mechanical unit, the RCA2610 can tolerate angles in pitch and roll that would

cause a gyroscopic unit to tumble.

On the attitude indicator you will see two yellow horizontal lines with a dot between them. The horizontal lines represent the wings

and the dot represents the nose of the aircraft. If the symbolic airplane dot is above the horizon line (more blue background) - the

aircraft is nose up. If the symbolic airplane dot is below the horizon line (more brown background) - the aircraft is nose down.

Whenthedotandwingsareonthehorizonline,youareinlevelight.Ifthelinesrepresentingthewingsrolltotheleftortheright,

the aircraft is probably starting a turn. The actual bank angle is calibrated around the circumference of the instrument dial. The

pitch angle is indicated by a series of calibration lines, each representing 5° or 10° of pitch.

1.2 PHYSICAL DESCRIPTION

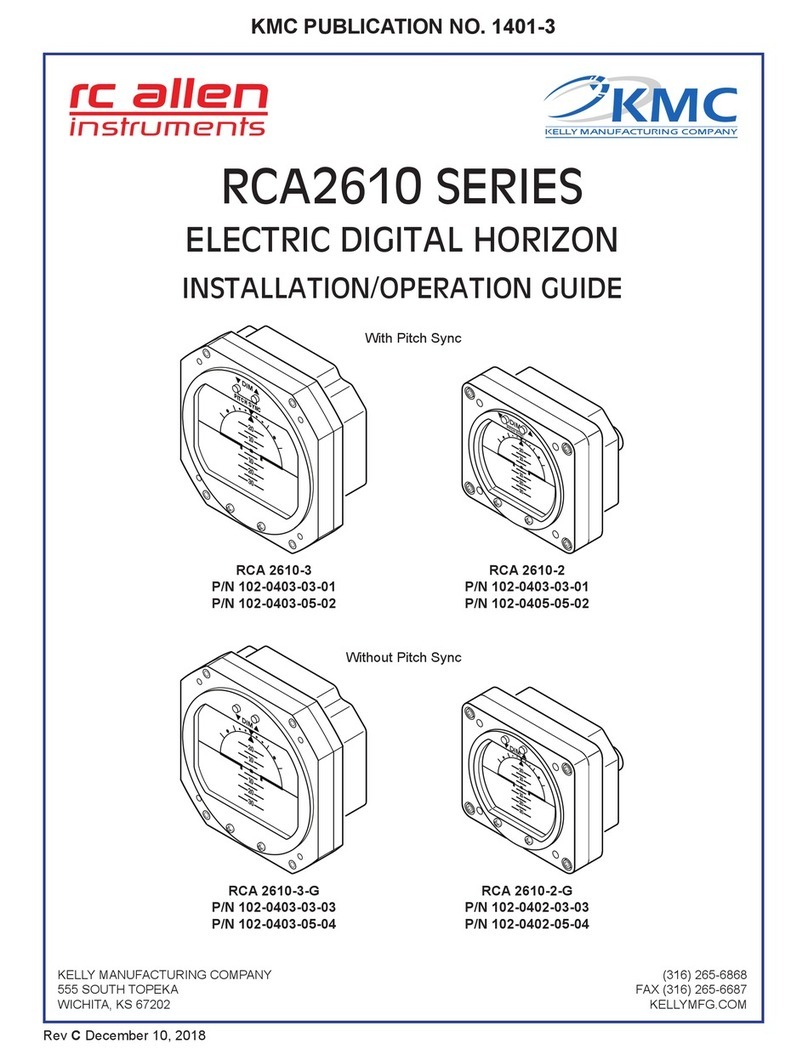

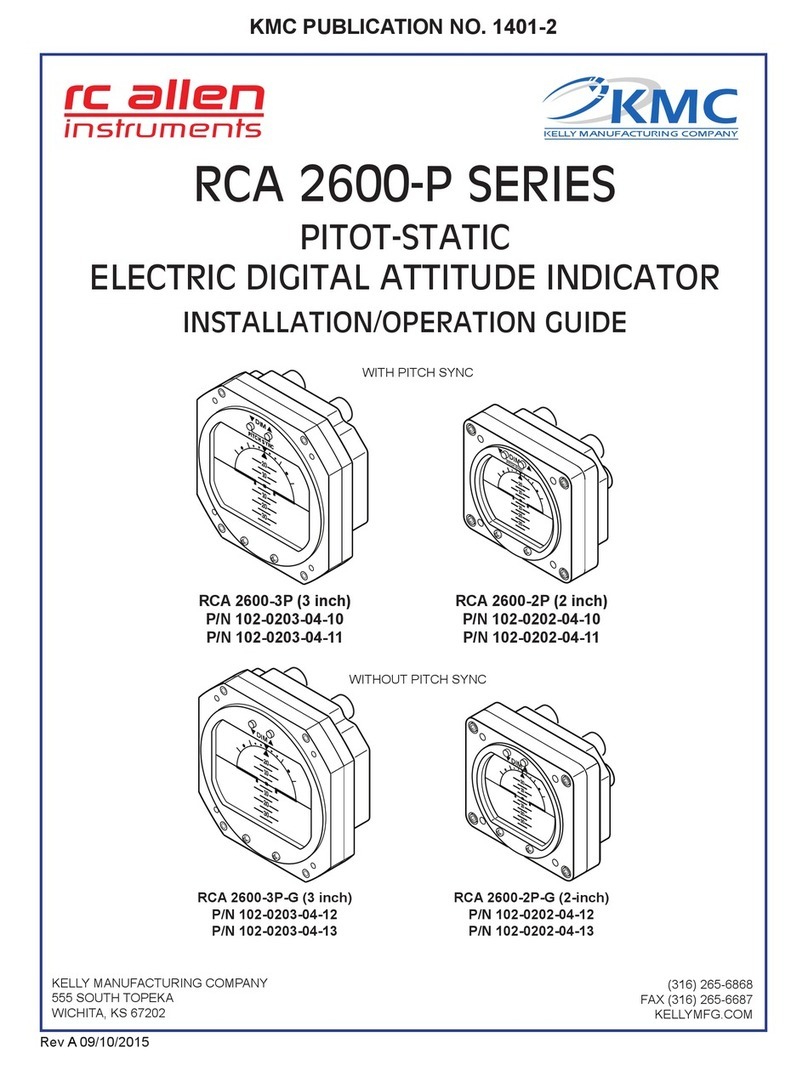

There are two basic models, the RCA2610 which has Pitch Sync and the RCA2610-G (G for general use) which does not have

Pitch Sync. The Pitch Sync feature allows the pilot to adjust the symbolic airplane to match the horizon during pitch up or pitch

downlevelight.Bothversionscomeinstandard3inchand2inchsizes.Refertotable1.1belowforleadingparticulars.

OPERATING VOLTAGE.......................................................................................................................................... 9 to 32VDC

STARTING CURRENT............................................................................................................ 9VDC: 0.18 to 0.22 AMPs MAX

RUNNING CURRENT ...................................................................................... (14VDC SYSTEM) ..................0.20 AMP MAX

(28VDC SYSTEM) ..................0.15 AMP MAX

CIRCUIT BREAKER SIZE............................................................................................................................................... 1 AMP

SETTLING ERROR........................................................................................................... 1º MAXIMUM IN ROLL AND PITCH

OPERATING TEMPERATURE RANGE.............................................................................................................-20º TO +55º C

MATING CONNECTOR ........................................................................................................MS3116E8-4S OR EQUIVALENT

WEIGHT ........................................................................................................... RCA2610-3 ......................................... 6.75 oz

RCA2610-2 ......................................... 4.75 oz

DIMENSIONS/PANEL CUTOUT .....................................................................................................SEE FIGURES 1.1 and 1.2

EYE VIEWING ANGLE ENVELOPE ....................................................................Horizontal Left and Right: 35°Left, 35°Right

Vertical Up and Down: 35°Up, 35°Down

Minimum distance from display surface: 6 inches

Maximum distance from display surface: 48 inches

SOFTWARE VERSION..............................................................................................................Version 2.0.6 and 2.0.7 (NVG)

FAA SPECIFICATION CONFORMANCE............................................................................... DO-160G and DO-178B Level C

SeeAppendixCforTSOCerticationbypartnumber

MEETS OR EXCEEDS ........................................................................................................... AS8034B, AS8004 and AS396B

TABLE 1.1, LEADING PARTICULARS