X-band 12kW Upmast Magnetron Transceiver

Chapter 1: Contents

HBK-2300-3 Issue 2

Page 3 of 40

1 Contents

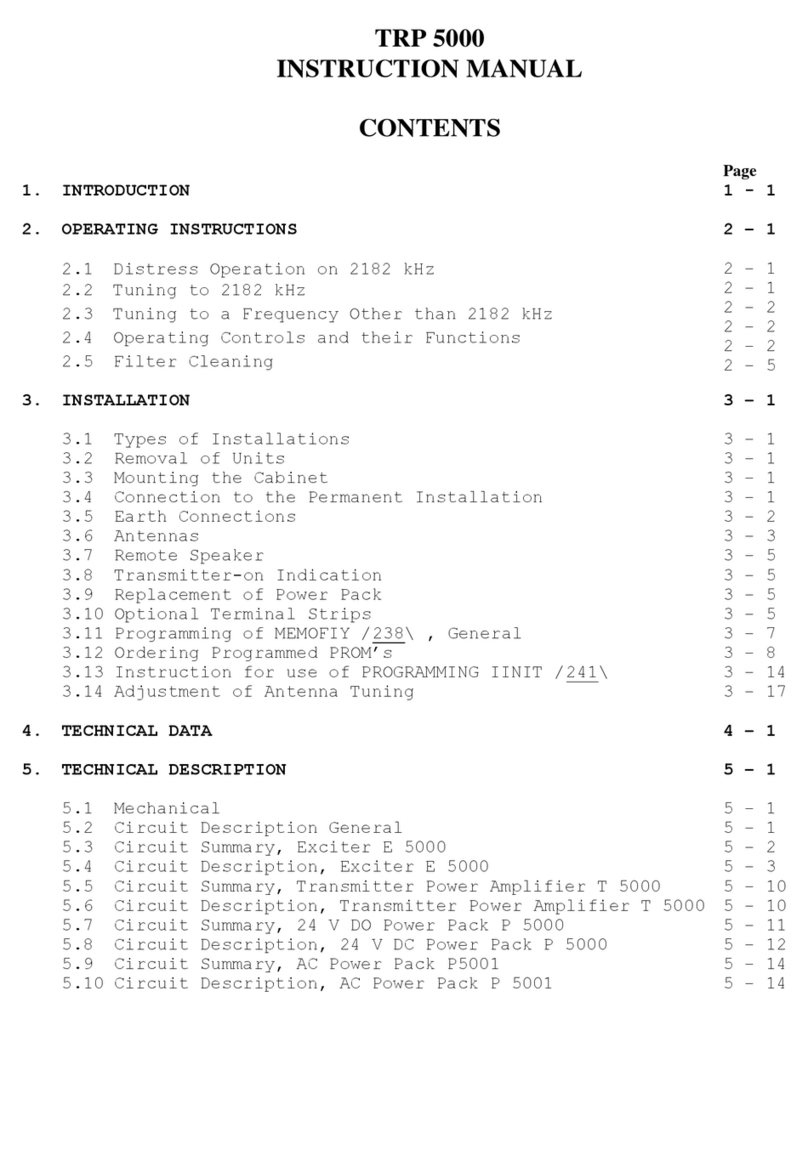

1Contents ......................................................................................................................................... 3

2Health & Safety............................................................................................................................... 5

3General Notices.............................................................................................................................. 9

3.1 Suggested tools ......................................................................................................................................... 9

3.2 Fitting kit contents ...................................................................................................................................... 9

3.3 Disclaimers .............................................................................................................................................. 10

3.4 Declaration of conformity ......................................................................................................................... 10

4Typical system ............................................................................................................................. 11

5Mechanical installation................................................................................................................ 13

5.1 Location requirements.............................................................................................................................. 13

5.2Transceiver installation ............................................................................................................................ 14

5.3 Antenna installation.................................................................................................................................. 16

5.4 E70352 Power supply .............................................................................................................................. 17

5.5 DIMENSIONS .......................................................................................................................................... 19

5.5.1 Transceiver ..................................................................................................................................... 19

5.5.2 Mounting hole dimensions............................................................................................................... 20

5.5.3 E70352 DC Power Unit ................................................................................................................... 21

5.6 Compass safe distances .......................................................................................................................... 21

6Cabling guidance .........................................................................................................................23

6.1 General advice......................................................................................................................................... 23

6.2 Grounding ................................................................................................................................................ 24

7CONNECTION DETAILS .............................................................................................................. 25

7.1 Transceiver .............................................................................................................................................. 25

7.2 Longer LAN cable .................................................................................................................................... 25

7.3 Power Supply........................................................................................................................................... 26

7.4 Breaker and fuse ratings .......................................................................................................................... 27

8Setting to work .............................................................................................................................29

8.1 Radar scanner initial power on test.......................................................................................................... 29

8.2 Radar checks ........................................................................................................................................... 29

8.3 Check and adjust bearing alignment........................................................................................................ 30

8.4 Troubleshooting ....................................................................................................................................... 31

9Specification.................................................................................................................................33

10 Optional AC/DC power supply ............................................................................................... 35

10.1 Installation ........................................................................................................................................... 35

10.2 Grounding............................................................................................................................................ 35

10.3 Termination.......................................................................................................................................... 36

10.4 Specifications ...................................................................................................................................... 36

10.5 Operation............................................................................................................................................. 36

10.6 Maintenance ........................................................................................................................................ 36

11 Contacting Kelvin Hughes ..................................................................................................... 37