9

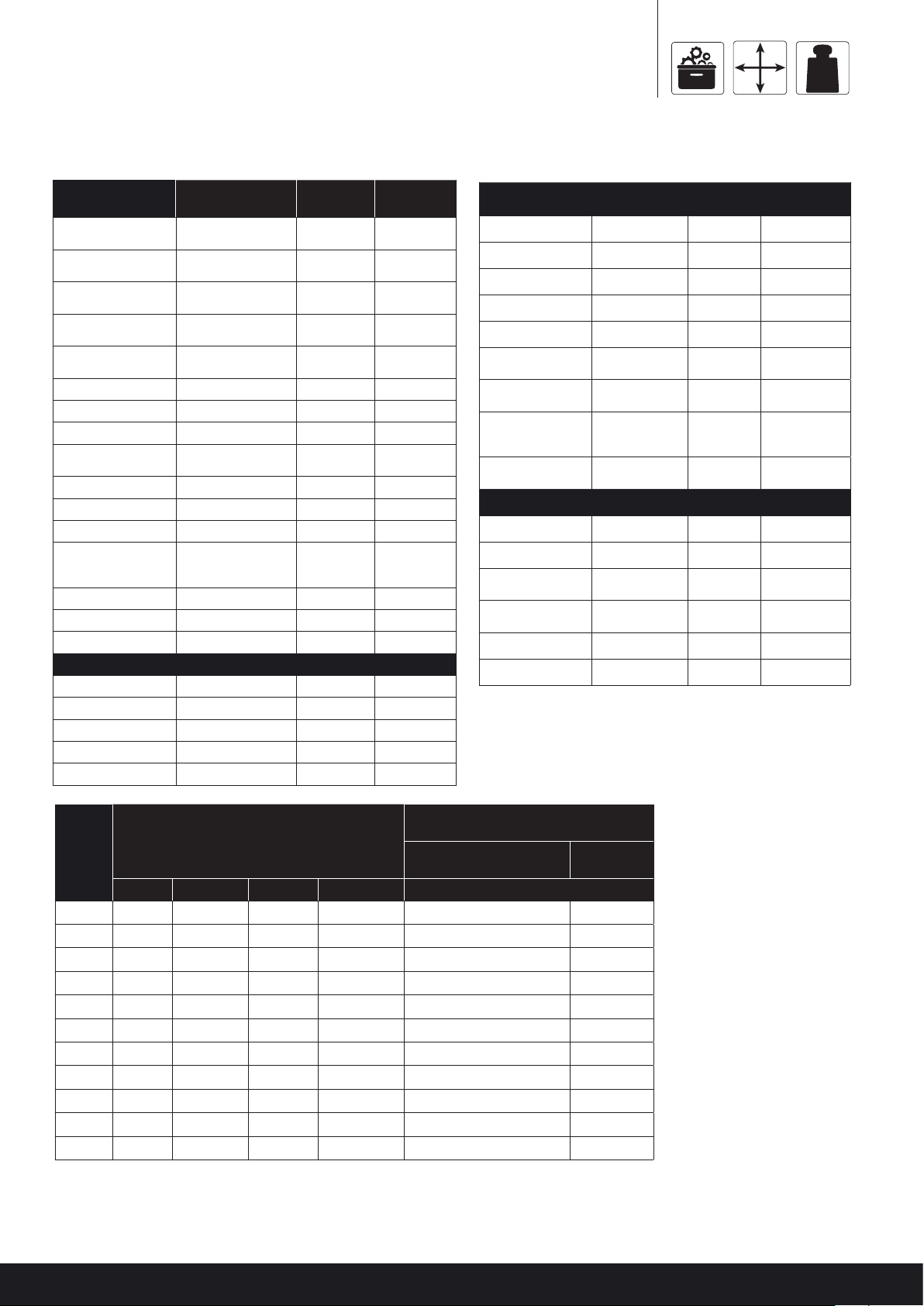

SPARES PART

NUMBER

SAP

NUMBER USED ON

FANSET 400mm 480V-

3PH 231-9040-0443 100464229 KME

FAN SET 400mm

230V- 1PH 231-9040-0421 100464227 KME

Drain Connection (1"

BSP) 261-763-001 100465376 All Models

Drain Connection

Gasket 248-811-002 100465076 All Models

Axial Fan Set 26°Pitch,

415V, 3Ph, 50Hz 231-845-261 100464139 All Models

Motor 231-845-261-MTR 100464141 All Models

Impeller 231-845-261-IMP All Models

Fan Guard 231-845-261-GUARD 100464140 All Models

380/465V, 3Ph, 60Hz,

Aerofoil Fan Set 231-845-161 All Models

Motor 231-845-161-MTR All Models

Impeller 231-845-161-IMP All Models

Fan Guard 231-845-161-GUARD All Models

220/240V, 1Ph,

50/60Hz, Aerofoil

Fan Set

293-400-106 All Models

Motor 293-400-106-MTR All Models

Impeller 293-400-106-IMP All Models

Fan Guard 293-400-106-GUARD 100532012 All Models

DEFROST ELEMENTS (Coil heaters)

530W 230V U Bend 215-260-440 100461666 KME50

800W 230V U Bend 215-260-660 100461670 KME60

1060W 230V U Bend 215-261-080 100461675 KME80, 95

800W 115V Straight 215-410-800 100461712 KME115, 140

940W 115V Straight 215-410-940 100461714 KME175

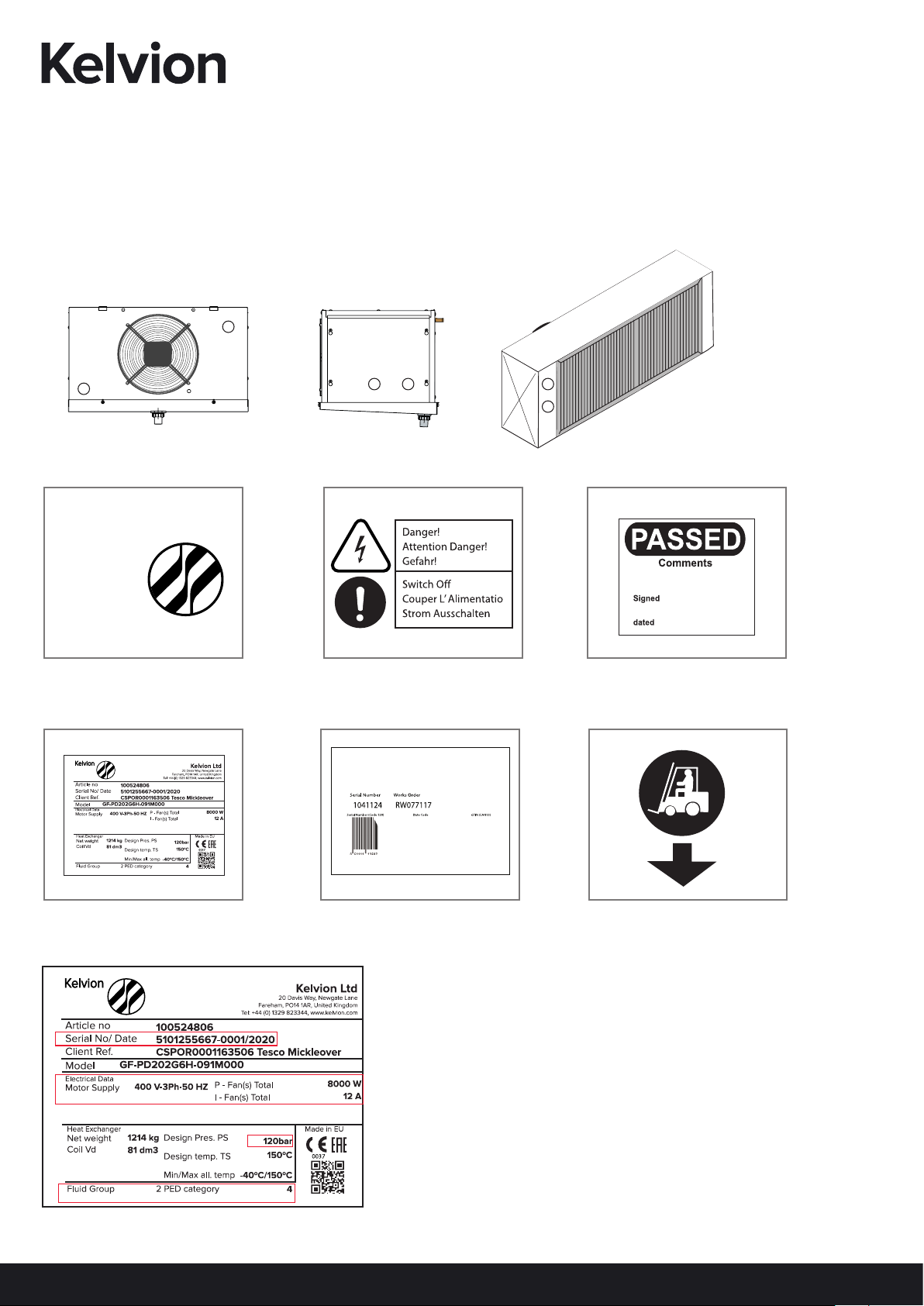

UNIT

DIMENSIONS

mm

WEIGHTS (APPROX)

Kg

REF

CHARGE WEIGHT

A B C D 6 FPI, 4 FPI, 3 FPI

KME50 350mm 1007mm 715mm 1011mm 2.1Kg 85Kg

KME60 350mm 1332mm 1040mm 1336mm 2.9Kg 112Kg

KME80 400mm 1682mm 1390mm 1686mm 2.6Kg 129Kg

KME95 450mm 1682mm 1390mm 1686mm 3.9Kg 139Kg

KME115 500mm 2357mm 2065mm 2361mm 3.8Kg 170Kg

KME140 500mm 2357mm 2065mm 2361mm 5.6Kg 195Kg

KME175 500mm 2732mm 2440mm 2736mm 6.6Kg 217Kg

KME232 650mm 2357mm 2065mm 2361mm 8.0Kg 312Kg

KME282 650mm 2357mm 2065mm 2361mm 11.8Kg 346Kg

KME352 850mm 2732mm 2440mm 2736mm 14.1Kg 365Kg

KME353 850mm 2732mm 2440mm 2736mm 14.1Kg 406Kg

lbs

DEFROST ELEMENTS (Draintray)

265W 230V Straight 215-210-220 100461630 KME50

400W 230V Straight 215-210-330 100461631 KME60

530W 230V Straight 215-210-440 100461633 KME80, 95

800W 230V Straight 215-210-660 100461637 KME115, 140

940W 230V Straight 215-210-780 100461638 KME175

Peripheral Heater

300W 215-290-406 100461687 All Models

Peripheral Heater Kit SPR-290-505 100513470 KME Axial Fans

Only

Fanplate Heater

(Caution required

due to Plastic Guard)

215-290-201 100461686 All Models

Anticreep clips (1 per

coil heater) 227-762-025 100463285 All Models

CASEWORK PARTS

Drain Pan 20-034 100459676 KME50

Drain Pan 20-035 100459681 UKME60

Drain Pan 20-036 100459686 KME80 /

KME95

Drain Pan 20-037 100459691 KME115 /

KME140

Drain Pan 20-038 100459696 KME175

End Cover 20-010 100459384 KME All Models