OPERATING HINTS

To get the best fromyourKemlan heater it is essentialthat youuse good firewood,anduseit correctlyManypeople do not understandthe

principle of usinga woodburningappliance and wesuggestthatit willbew orthyourwhiletostudy thefollowingextractfromawellknown

Americanpublication.

PRINCIPLES OF COMBUSTION: HOW WOOD BURNS

Technically,w ooddoes notburn. What burns is the volatiles and charcoalthat arecreated. That is why woodwillnotcatch on fire

immediately w henyouputa match to it; it has to firstundergothe chemical changesthat createthevolatiles, and a match does not create

enough heat to activatethe process.As kindlingand paper evaporatethe moisture in the wood,thew oodabsorbsheat.Ata certainpoint,

gases are given off and w hen these volatiles reach 480 degrees F, or the “Flash point”, as it is called, they w ill burst into flame if sufficient

oxygenis present.The volatiles give off moreheat than does charcoal,w hichis whyafirew ithflames (whichburnthevolatiles) produces

more heat than one that is all charcoal.

Since the volatiles are gases and sinceheat rises,taking the gases withit,it is very easy tocreateasituation in w hich mostof thevolatiles go

up the chimney almost as soonas they areproduced.This is whathappens witharoaringfireand, to a lesserextent,withan open fire.One of

the reasons(butonly one) that a freestandingwoodstoveproducesmoreheat than an open fireisthat the volatiles arecontained withinthe

firebox andare not soquickly dissipatedup the chimney. A stovethat isbaffledismerely one that has interiorconstructiondesignto keep the

volatiles in the fireboxlonger;the longer they are in the firebox,themore completely they burn. The more completely they burn,the more heat

is produced. It’s that simple.

Since the flames burn the volatiles and produceheat, the ideal situation is the longestpossible flame path. As soonas wood burners

understandthis,they tried to devisewaysof makingthe flame path longerthan in an ordinary openfire.Even though the role of oxygenin

combustion w as notunder- stood in Ben Franklin’s time, Franklin did realize the importance of more completely burned volatiles. His solution

was totry toinventa downdraft stove

–one that sentthe volatiles back downthroughthefire–but he neversucceededingetting it to work.A downdraftgoesagainstthenature of

volatiles, w hichistorise.In more recenttimes, there havebeen some successfuldowndraft –or partialdowndraft –stoves createdandsome

of the fireplacestovesandunits utilise this principle. Ideally, it wouldbebest if the volatiles couldbe redirecteddown throughthefireseveral

times, until they w ereal- most totally consumed.This wouldnotonly make the maximum use of the heat potential of the wood;it wouldreduce

creosotebuild-upto almost zero.Perhaps someday an ingenious inventor w illdesign a unit that does this; sofarno has been able to.

MOISTURE AND COMBUSTION

As w ehaveseen,dry woodignites faster andburns better –w ithhigher heat production–than w etor greenw ood. Thedifferencebetween

the amount of heat producedby dry w oodandgreenwoodis sogreatthat a dry softwoodof goodgradew illproducemoreheat than green

hardwood.Greenw hiteash,for instance,is notas good a fuelas dry tamarack.

The reasonfor the superiority of drywoodis easy tounderstand.Heatcannot be produceduntil moisture has been drivenoff. Sinceevenso-

called seasoneddry woodcontains approximately 20percentmoisture, it takes time for any firetobegin producinguseable heat. Wet w ood,

whichcanhaveamoisture contentof over100 percent(dueto the waymoistureismeasured),willtake that much longer to produceheat.

Meanwhile,the firewillproducesmoke and creosoteandvery little heat. This was broughtsharply tomy attention whenIinstalled my first

woodheater. To my surpriseanddelight, I foundit comfortablyheatedeight rooms, w hereIhad expectedto heat only twoor three.After

some time, whenIhad someone helping me runthe fire,I suddenly noticed that the housew as chilly.Weadded more woodandadjustedthe

draftcontrols,butnothing wedidseemed to help. It finally occurredtome to checkthe woodpile.My friendhad been getting green woodfrom

a stackthat w as drying,insteadof fromthedry-woodstack.Thedifferencethegreenw oodmadew as sodramatic Iw illnever forgetit.

HOW TO TEST WOOD FOR DRYNESS

There are tw o easy w ays for even a novice to spot dry w ood. Dry w ood tends to “check”. Look at the log ends and you w ill see cracks radiating

fromthe centreof the log. If the logs havebeen split, the cracks willbeharder to findbecausew oodtends tosplit along the cracks.

Another testfordry w oodis thesoundit makes whentwologs arebangedagainst eachother. Green woodwillmake sortof a dull thud; dry

woodmakes a nice crisp,sharpsound. Onceyouhave heardthe two,youwillremember the difference.

FROM THE ABOVE EXTRACT SEVERAL FACTS BECOME APPARENT:

1. It is vital that your firewoodbedry andseasoned.

2. A good hot fireof kindling and smaller pieces of fuelmust be establishedbeforeadding larger logs.

3. The larger logs should be wellalight beforeslowingdownthecombustionbyadjusting the air intake.

4. A hot bed of coals needsto be maintained to ensurecontinuedcombustion in the firebox.

5. When new timber is added to the fireboxtheair controlshould be opened until the fuel is wellalight beforedamping it down again.This will

take from10 to 20 minutes.

6. When setting the controls forovernightburnyouwillneedto experiment withthesettings to suit yourparticulartypeof fuel.Very dense

hardwoodrequiresmoreairto combustand over damping w illresultin charringandsmoking causingthe glass in the door to become dirty.

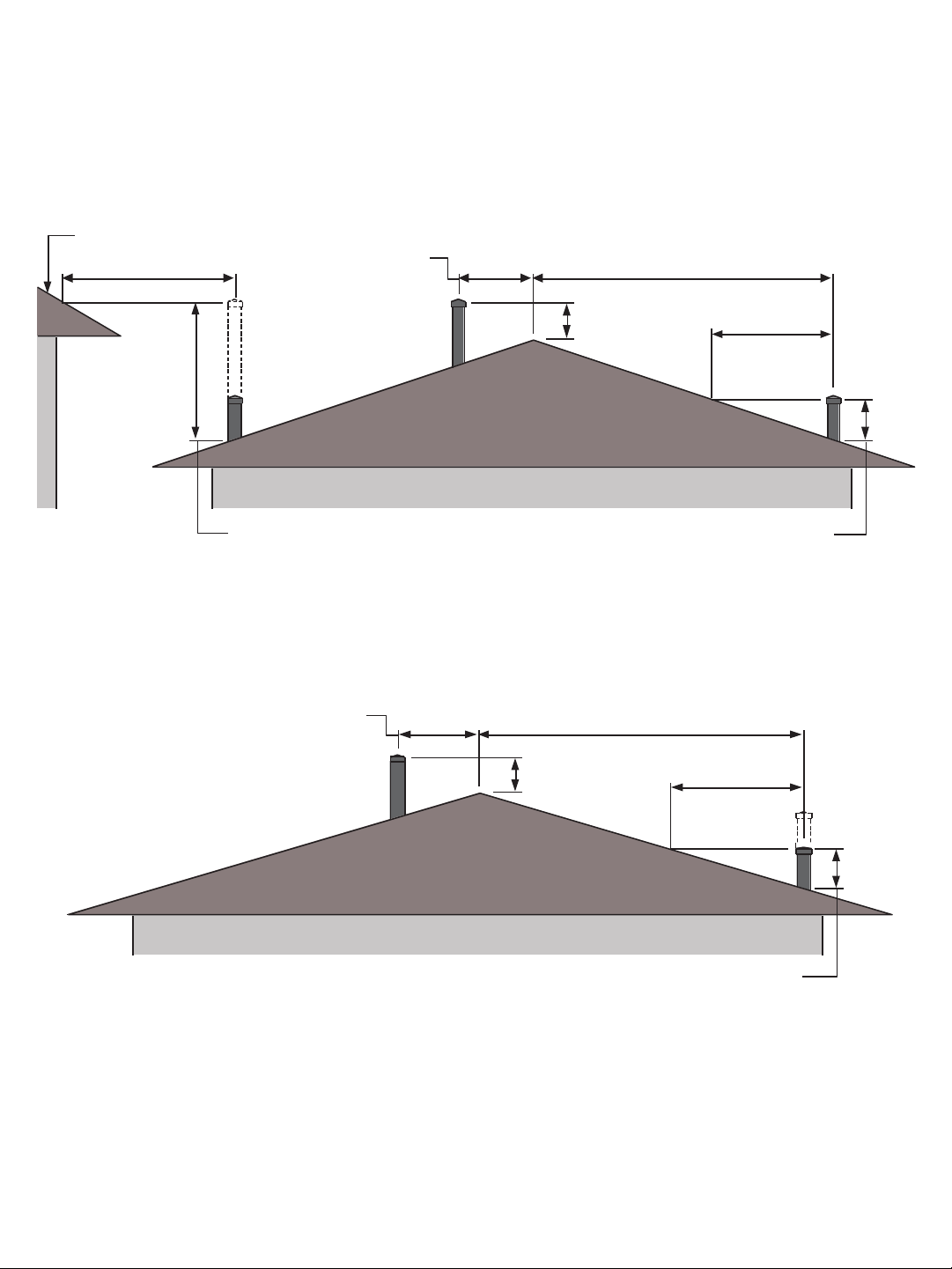

The same w illapply w ithfuelwhichis notfully seasonedor is not dry enough. Kemlan have followedapolicy since1969of checking on all

complaints about poor performanceof their heaters andapart froma few instancesof incorrect installation(mostly insufficientfluelength) all

problems havebeen directly related to incorrectoperationand/orpoor fuel.We know youwillexperiencemanyyears of satisfactionfromyour

heaterif youfollow theaboveadvice.