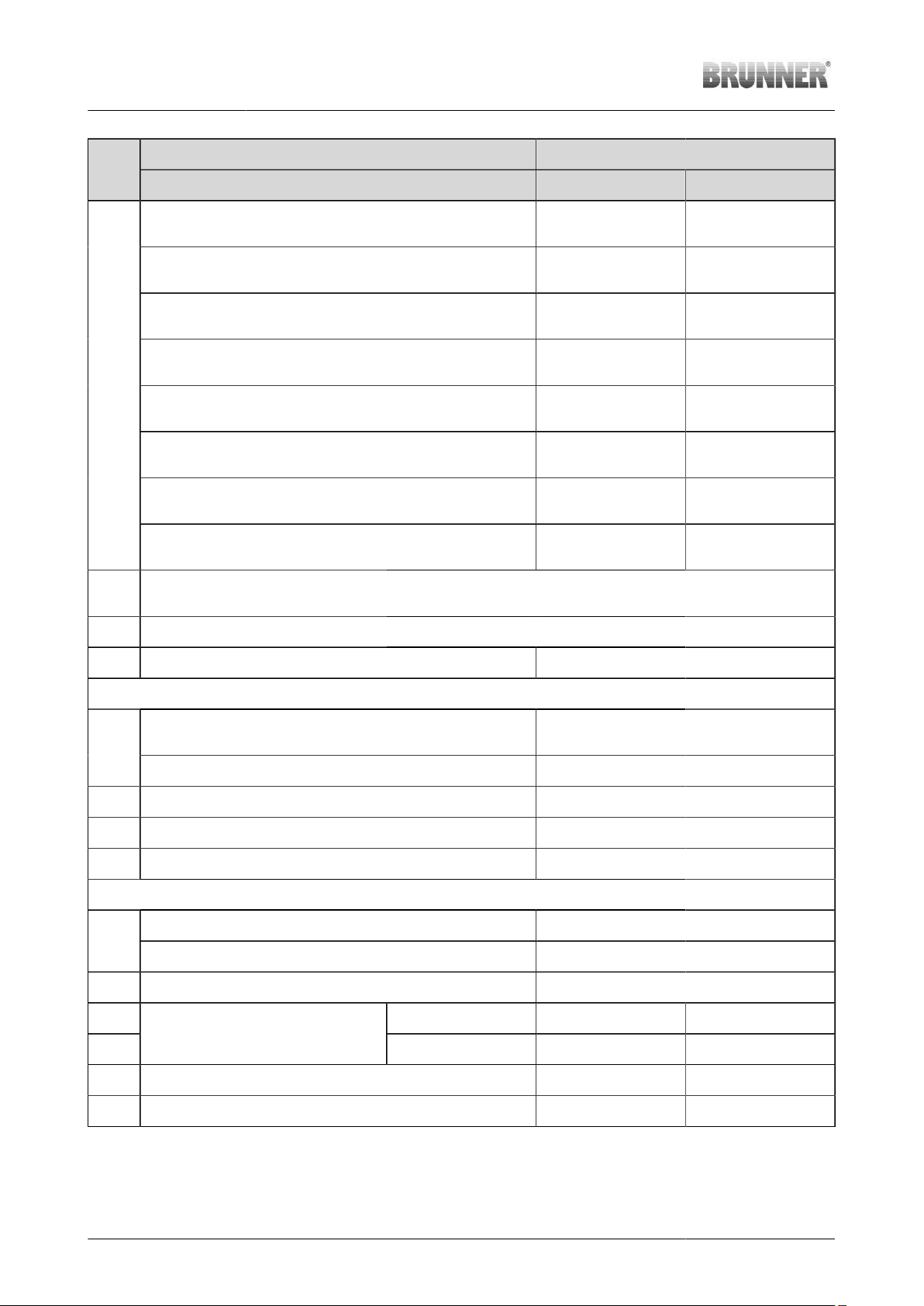

CONTENTS

1 Basic informations..................................................................................................... 3

2 Safety precautions..................................................................................................... 3

3 Specified symbols......................................................................................................4

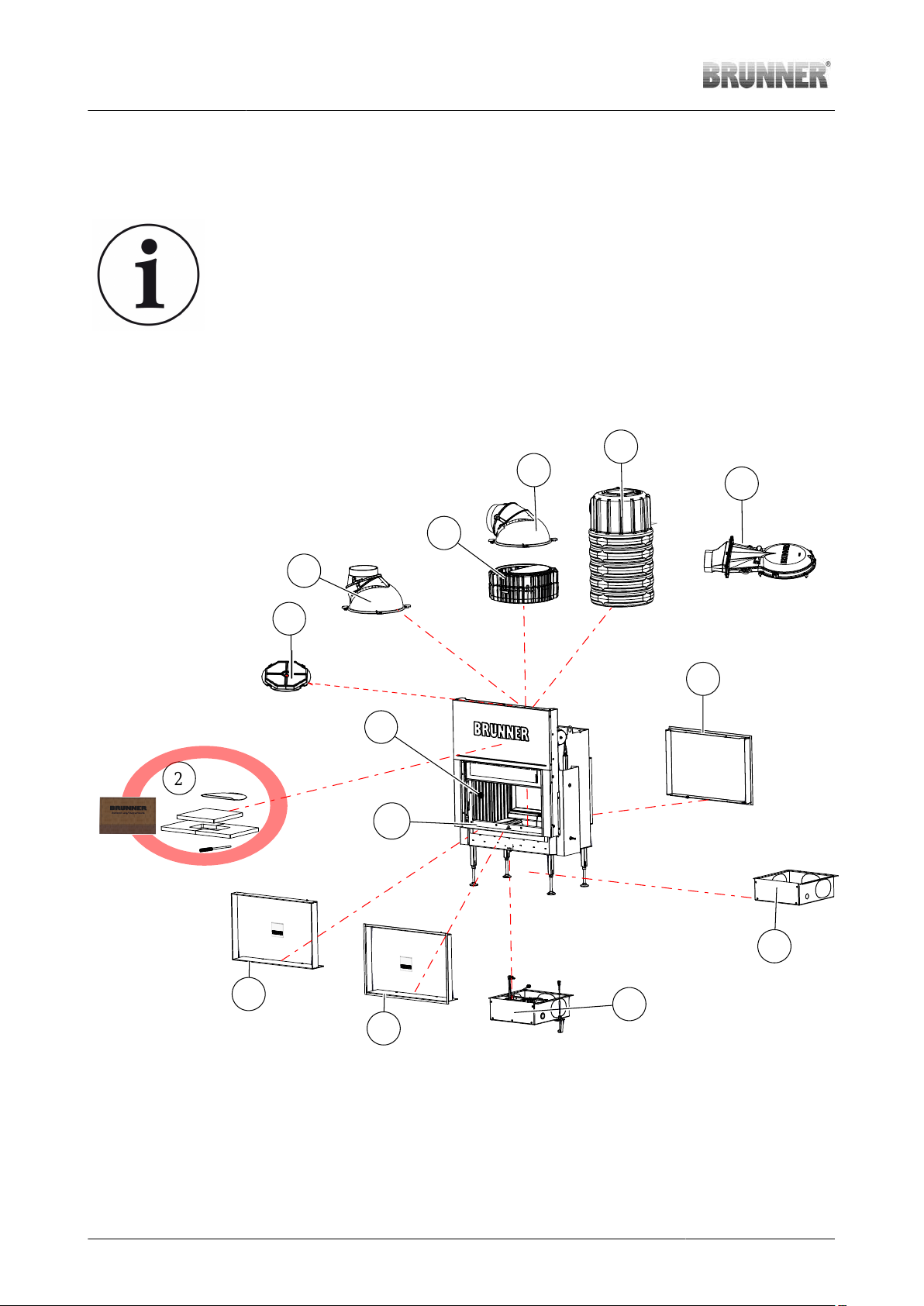

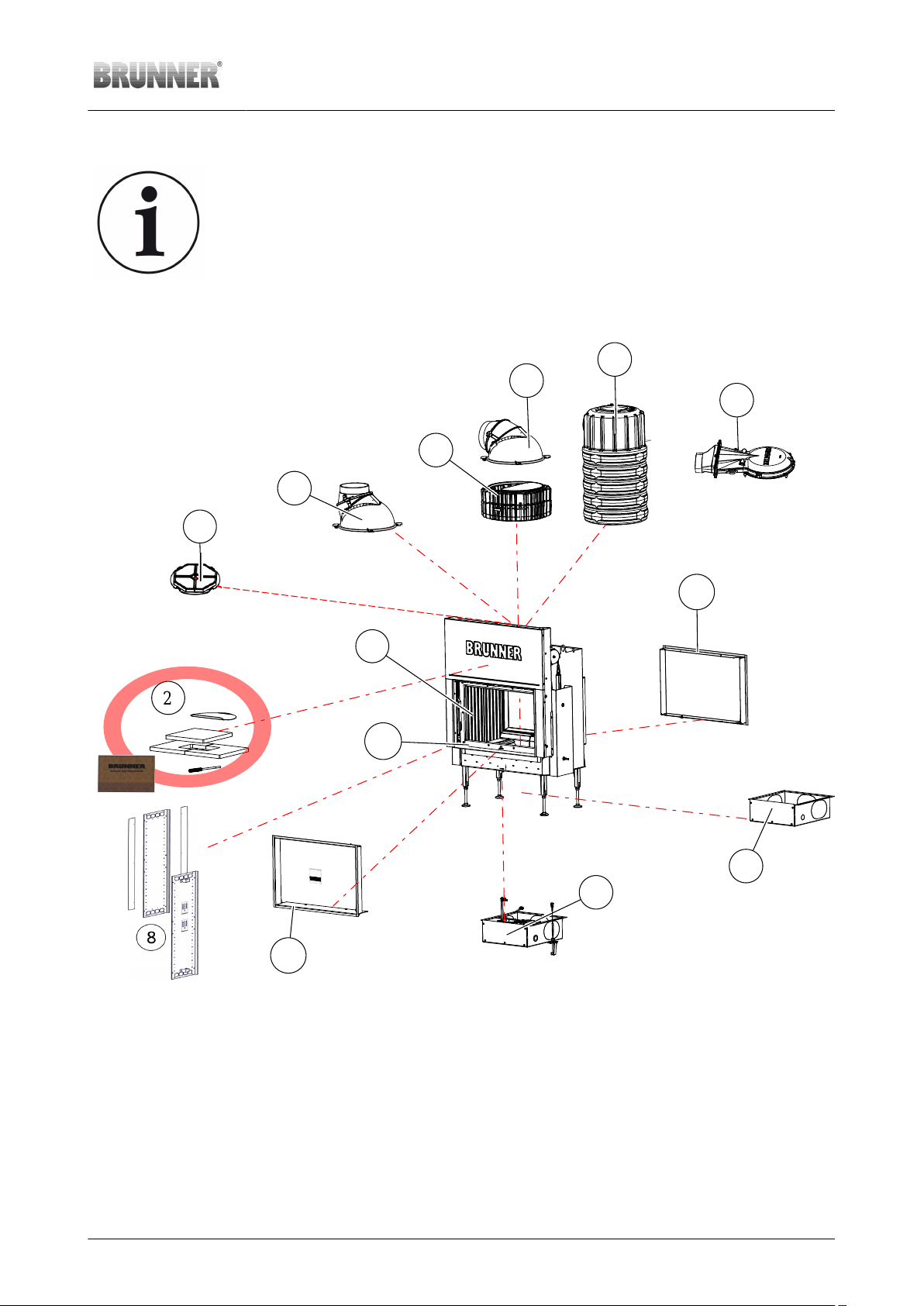

4 Delivery contents BKH 42-66 Tunnel....................................................................... 6

4.1 Catalytic converter (optional)........................................................................................................ 9

4.2 Air connection box (optional)...................................................................................................... 10

4.3 Heat exchanger rings (optional)..................................................................................................10

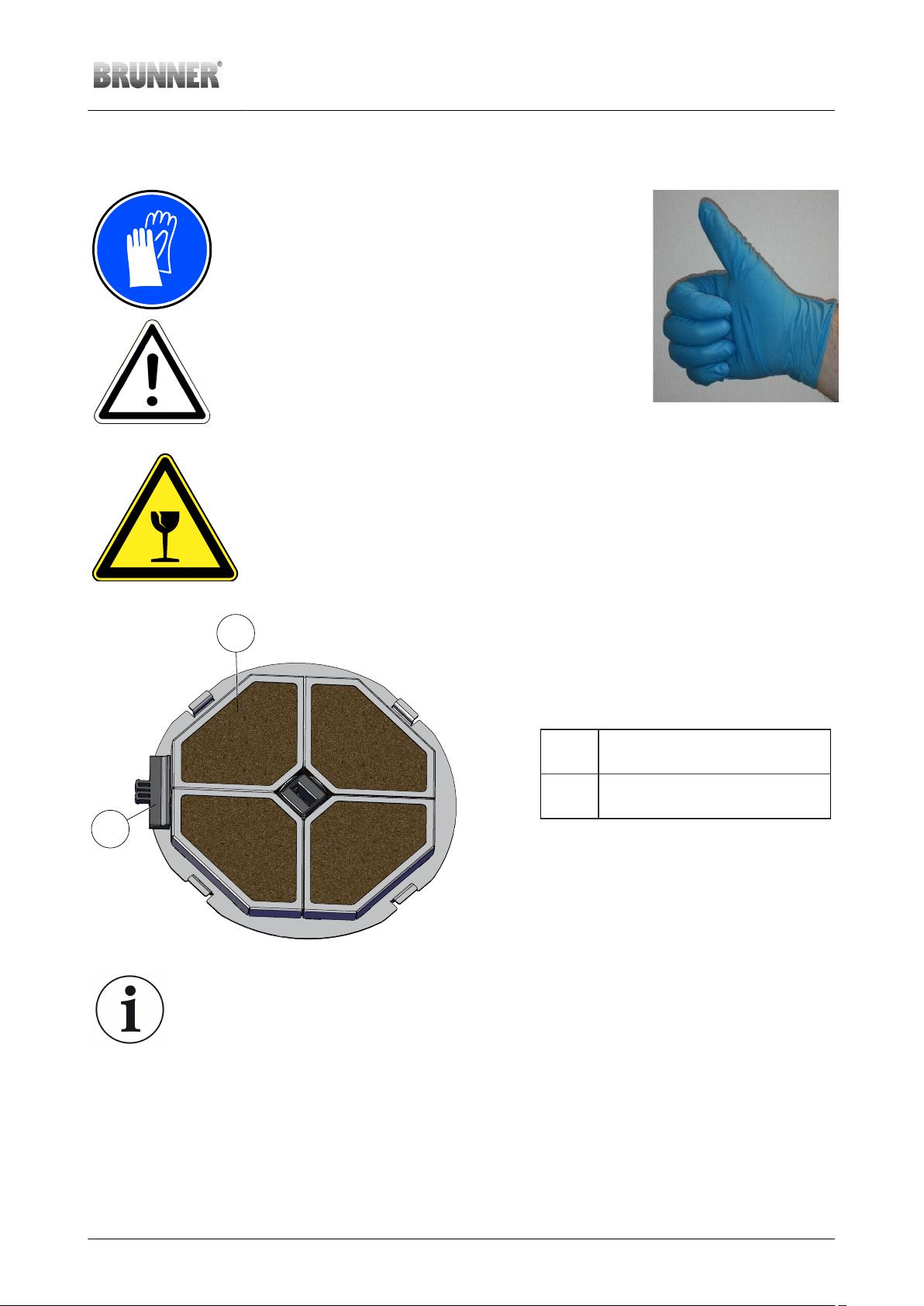

4.4 Heat protection panel for Tunnel DT-DT.................................................................................... 11

5 Safety distances BKH Tunnel................................................................................. 11

6 Setting up.................................................................................................................. 14

6.1 Remove the transport locks........................................................................................................ 14

6.2 Heat protection panel Tunnel DT-DT..........................................................................................15

6.3 Set up the fireplace.....................................................................................................................22

6.4 Variant with external combustion air connection........................................................................ 24

6.4.1 Bottom connection (B).................................................................................................. 26

6.4.2 Side connection (S)...................................................................................................... 32

7 Variant with EAS or EOS.........................................................................................37

8 Fitting: catalytic converter...................................................................................... 48

9 Fitting: deflection combustion chamber - Tunnel................................................ 52

10 Variants heat exchanger..........................................................................................61

10.1 Connection with catalytic converter............................................................................................ 61

10.2 Connection without catalytic converter....................................................................................... 62

10.3 Heat exchanger - cast iron dome............................................................................................... 66

10.4 Heat exchanger rings.................................................................................................................. 69

10.5 Heat exchanger - MAS............................................................................................................... 75

11 Frame variants..........................................................................................................83

12 Conversions, settings..............................................................................................87

12.1 Change: door hinge.....................................................................................................................87

12.2 Adjusting of self-closing door.................................................................................................... 100

12.3 Modification - lifting door: “non self closing”............................................................................. 108

13 Disposal...................................................................................................................111

14 Technical data........................................................................................................ 112

2 Installation Manual BKH 5.0 Tunnel 42-66 green (1.11) © 2023 Brunner GmbH