GHP Group, Inc.

Model: Large Wood Stove

Report Number:0418WS018E

TABLE OF CONTENTS

PREFACE...............................................................................................................(3 pages)

1. SAMPLING PROCEDURES AND TEST RESULTS........................................................4

Introduction..........................................................................................................................5

Individual Run summaries...................................................................................................6

Summary Tables

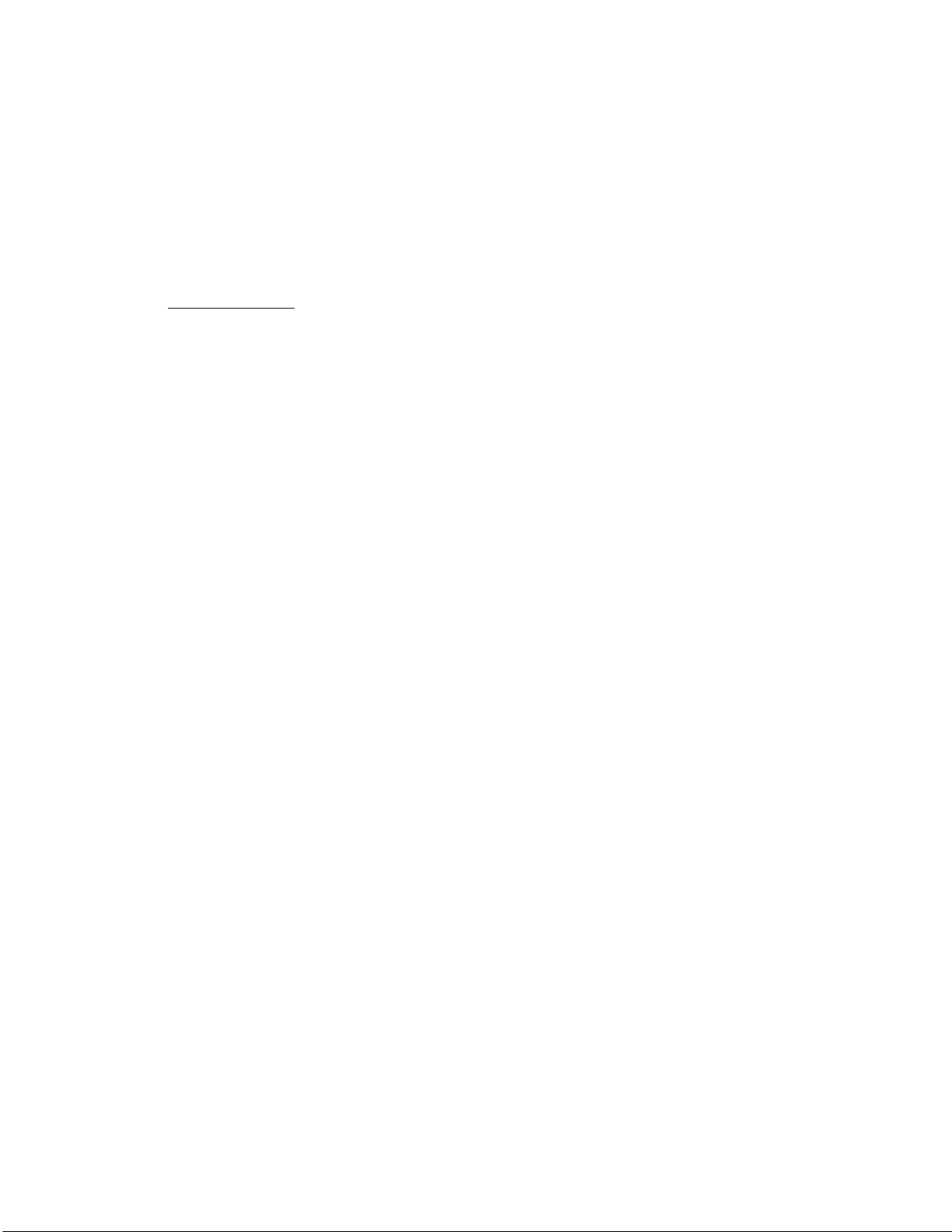

Table 1 - Particulate Emissions Results...............................................................................7

Table 2 - Particulate Emissions Results (First Hour)...........................................................7

Table 3 – B415.1 Efficiency and CO Emissions .................................................................7

Table 4 - Test Facility Conditions .......................................................................................8

Table 5 – Kindling and Start-up Fuel Description Summary..............................................8

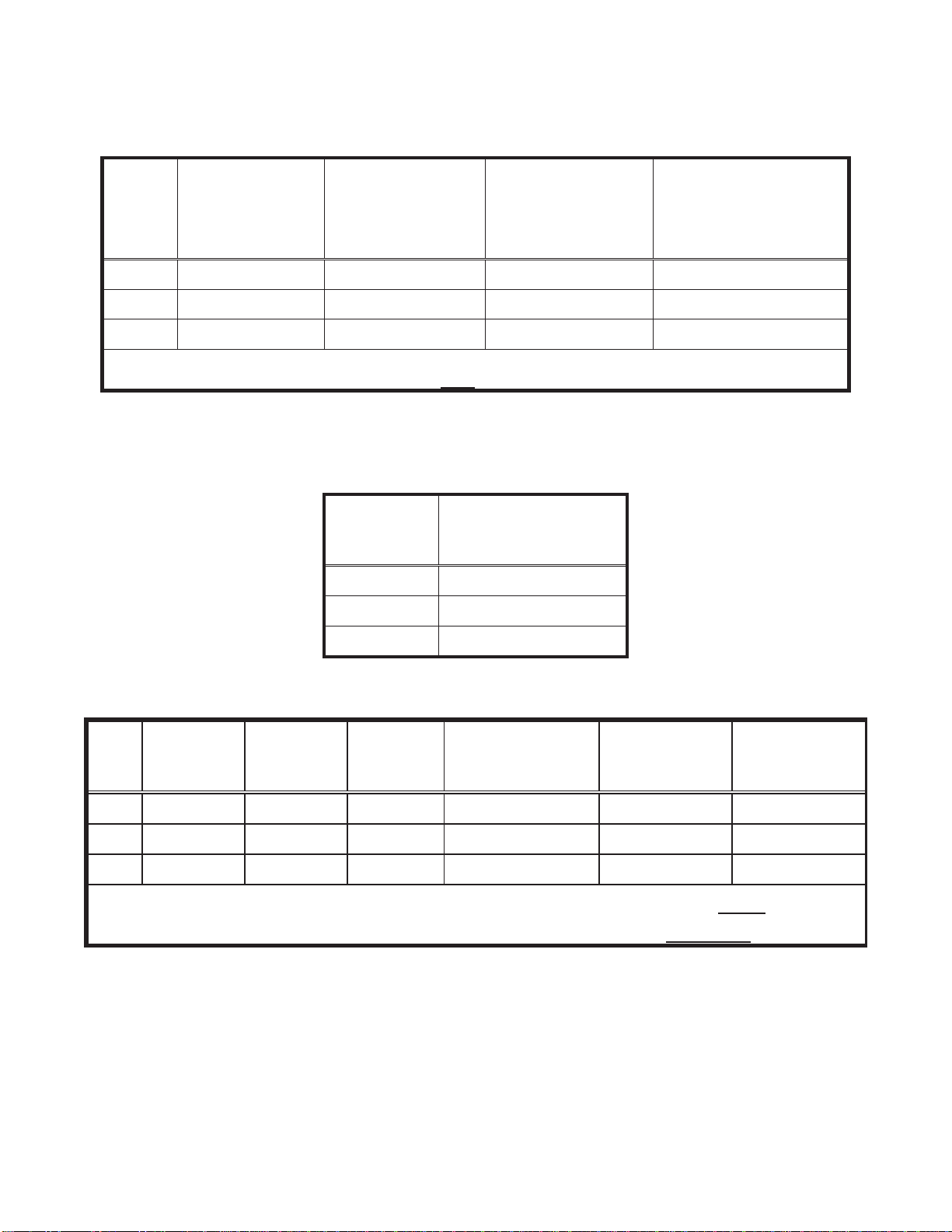

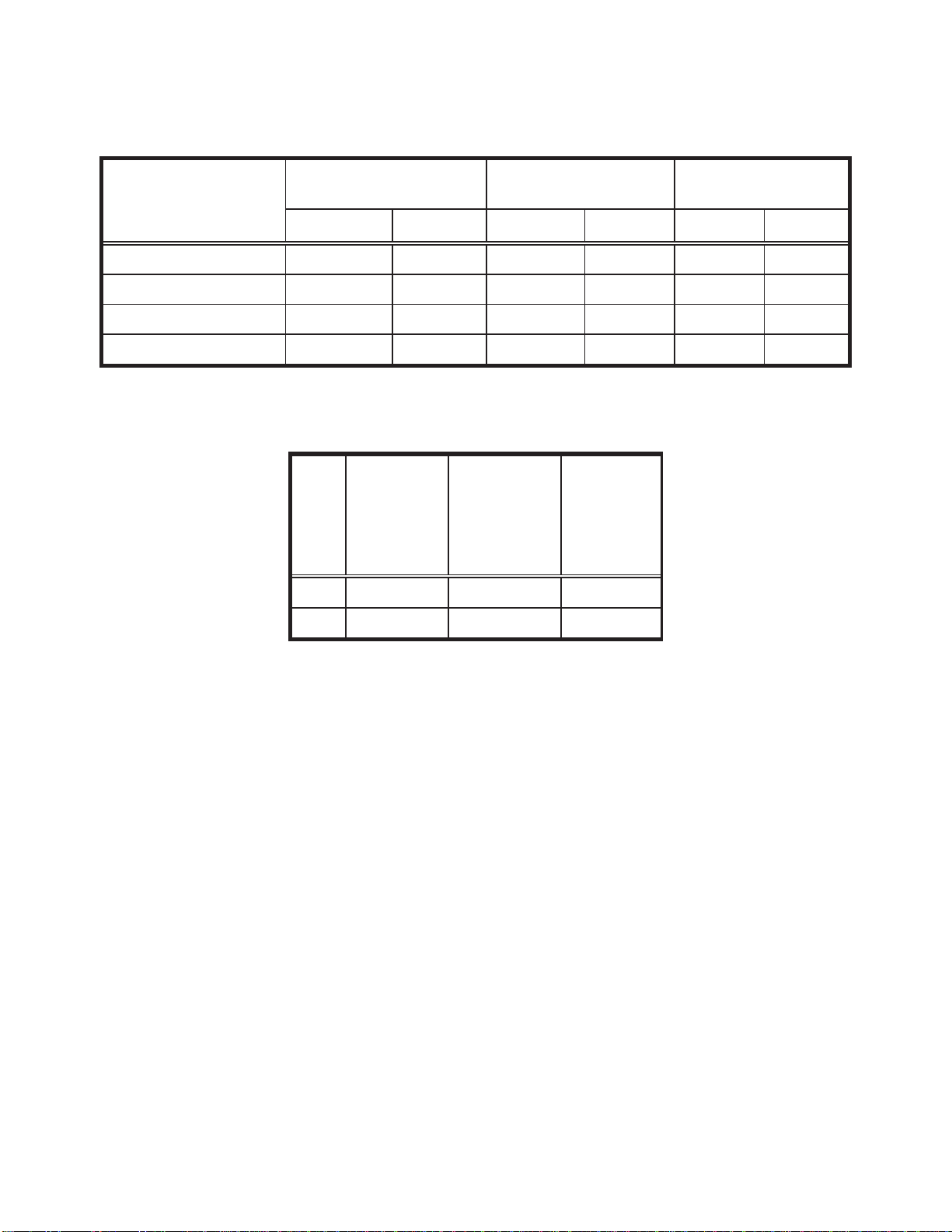

Table 6 - Fuel Measurements and Cordwood Descriptions - Test.......................................9

Table 7 - Dilution Tunnel Gas Measurements and Sampling Data.....................................9

Table 10 - Test Configurations..........................................................................................10

2. PHOTOGRAPHS/APPLIANCE DESCRIPTION/DRAWINGS......................................11

Fuel Photographs ...............................................................................................................13

Appliance Description .......................................................................................................17

Model Similarities..............................................................................................................18

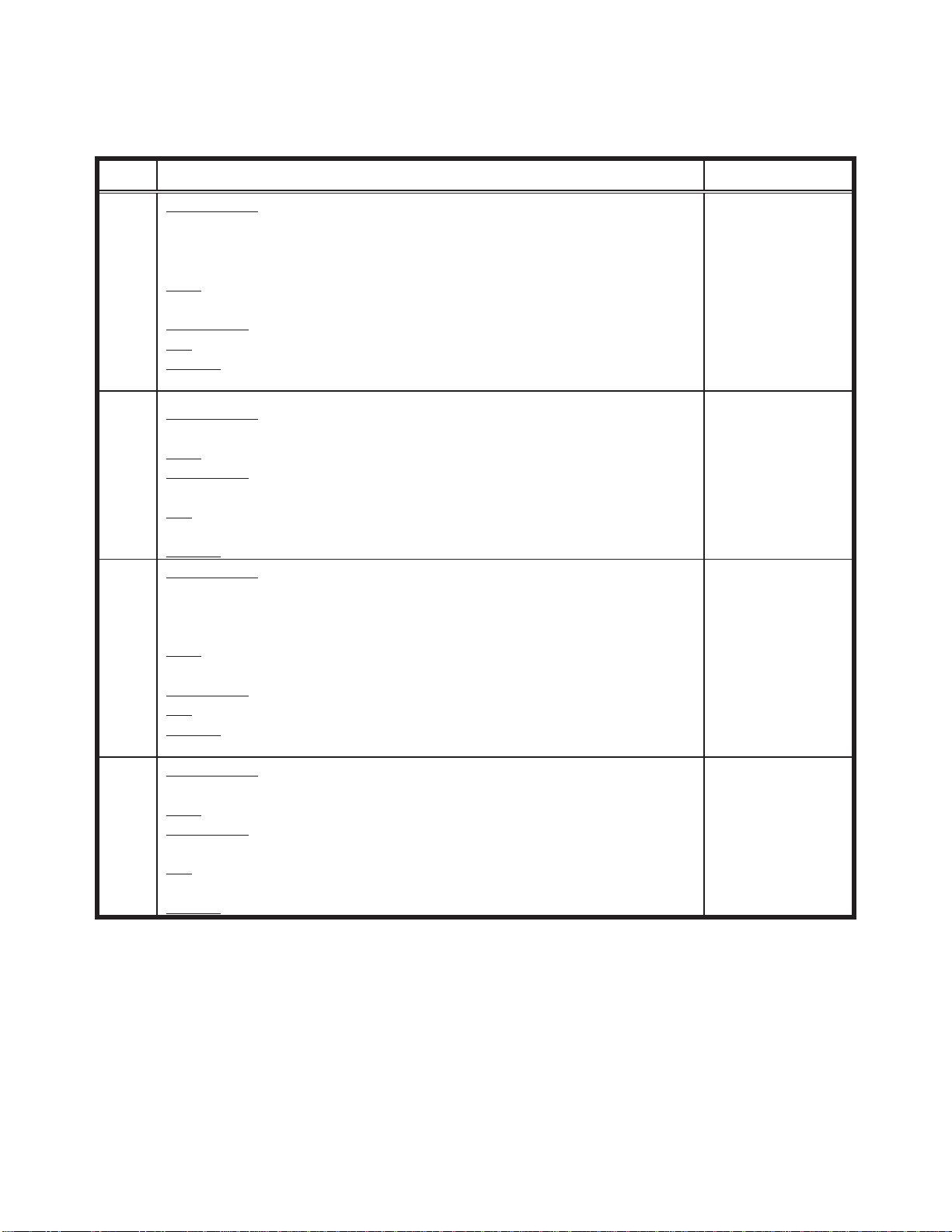

3. TEST DATA BY RUN......................................................................................................19

Run 1..................................................................................................................................27

Run 2..................................................................................................................................47

Run 3..................................................................................................................................57

Run 4..................................................................................................................................66

4. QUALITY ASSURANCE/QUALITY CONTROL..........................................................75

Sample Analysis.................................................................................................................77

Calibrations – ASTM E2515, ASTM E3053.....................................................................87

Example Calculations ......................................................................................................101

Appendix A Manufacturer’s Installation/Operation Instructions - Labels

Appendix B Alt-125 E3053 Letter

Appendix C Firebox Volume