OPERATOR’S HANDBOOK

Before using, cleaning or servicing the Cimbali M52 Fully Automatic, Milk Cooler or Cup

Warmer, always follow these basic safety precautions:

1. Read the instructions carefully before using the machines. Ensure that anyone who will be

involved with the cleaning or refilling of the machines also reads the instructions.

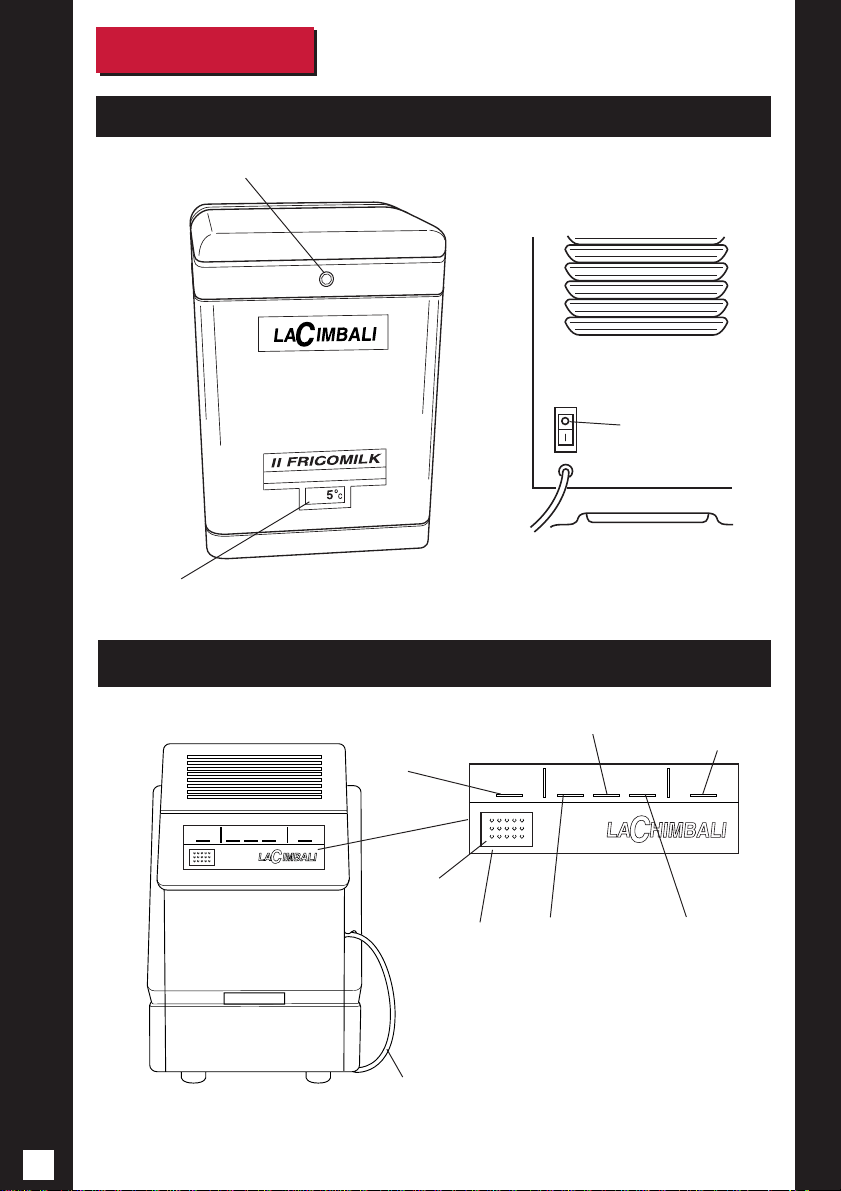

2. Eachofthemachinesis to be setup onastablehorizontal surface. Ensure that the ventilation

vents are free of obstructions.

3. The electrical supply leads should never trail from the machine and should always be kept

away from hot surfaces and sharp edges.

4. Theequipmentshouldbe located so thattheelectricalplugs are accessible fordisconnection.

5. Do not operate a machine if any part is damaged, e.g. electrical supply lead, until it has

been checked by a qualified Service Technician.

6. Never immerse a machine in water or any other liquid and never clean with a water jet.

7. If a machine should accidentally freeze up, call a Service Technician to check it before

switching on.

8. Ensure you are conversant with the ‘Health and Safety at Work and Electricity at Work

Regulations 1989’ (see Contents page).

ALWAYS ISOLATE A MACHINE FROM THE ELECTRICITY SUPPLY BEFORE

CLEANING AND SERVICING.

9. It is recommended that the machines are serviced by a Kenco trained Service Technician.

Important Safeguards

Copyright 2002 Kraft Foods.

The information in this Operator’s Handbook was correct at the time of going to print. Kraft

Foods reserves the right to change the specification without notice.

5