INSTALLATION INSTRUCTIONS

30" (76 CM) FREESTANDING GAS RANGE WITH

TRIPLE TASK OVEN DRAWER

INSTRUCCCIONES DE INSTALACION -

ESTUFA AUTONOMA A GAS DE 30"(76 ClVDCON CAJON

DE HORNO DE TRIPLE FUNCION

Table of Contents/indice

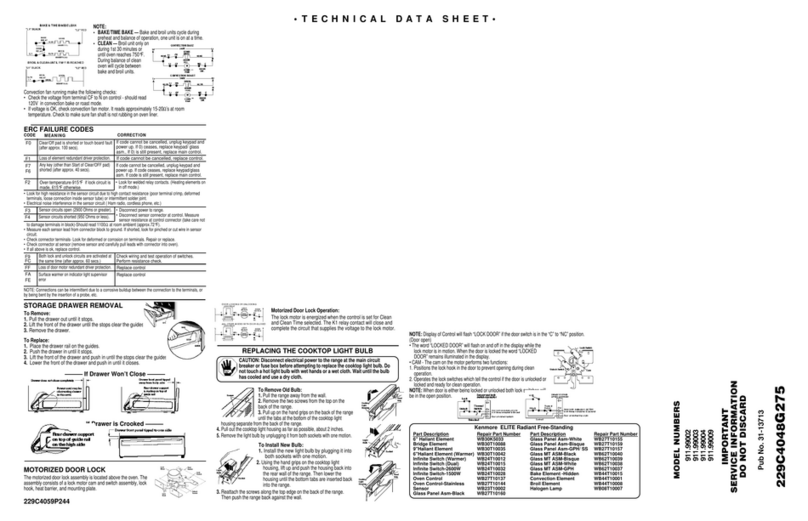

RANG E SAFETY .................................................... 2

INSTALLATION REQUIREMENTS ....................... 3

Tools and Parts .................................................. 3

location Requirements ...................................... 3

Electrical Requirements ..................................... 5

Gas Supply Requirements ................................. 5

INSTALLATION INSTRUCTIONS ......................... 7

Unpack Range .................................................... 7

Install Anti-Tip Bracket ....................................... 7

Level Range ........................................................ 8

Make Gas Connection ....................................... 8

Electronic Ignition System ................................ 10

Replace Oven Racks and Triple Task

Oven Drawer ..................................................... 11

Complete Installation ....................................... 11

GAS CONVERSIONS .......................................... 12

/p Gas Conversion .......................................... 12

Replace Access Panel, Oven Racks and

Triple Task Oven Drawer .................................. 13

Complete Installation ....................................... 14

Natural Gas Conversion ................................... 14

Replace Access Panel, Oven Racks and

Triple Task Oven Drawer .................................. 15

Complete Installation ....................................... 15

ANTI-TIP BRACKET TEMPLATE ...................... 34

SERVICE NUMBERS ...................... BACK COVER

SEGURIDAD DE LA ESTUFA .............................. 17

REQUISITOS DE INSTALACION ........................ 19

Piezas y herramientas ....................................... 19

Requisitos de ubicaci6n .................................... 19

Requisitos el_ctricos ......................................... 21

Requisitos del suministro de gas ...................... 21

INSTRUCCIONES DE INSTALACION ................ 23

Desempaque la estufa ...................................... 23

Instalaci0n del soporte anti-vuelco ................... 23

Nivelaci(_n de la estufa ...................................... 24

Conexion del suministro de gas ....................... 24

Sistema de encendido electr0nico ................... 25

Vuelva a colocar las parrillas del homo y

el cajon del homo de triple funcion .................. 27

Complete la instalacion ..................................... 27

CONVERSlONES DE GAS ................................... 28

Conversi(_n de gas LP....................................... 28

Vuelva a colocar el panel de acceso,

las parrillas del homo y el caj6n de homo

de triple funci6n ................................................ 30

Complete la instalacion ..................................... 30

Conversion de gas natural ................................ 30

Vuelva a colocar el panel de acceso,

las parrillas del homo y el caj6n de homo

de triple funci6n ................................................ 32

Complete la instalacion ..................................... 32

PLANTILLA DEL SOPORTE ANTI-VUELCO ...... 34

NUMEROS DE SERVICIO ..... CONTRAPORTADA

IMPORTANT:

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

Save installation instructions for local electrical inspector's use.

tMPORTANTE:

tnstalador: Deje las instrucciones de instalaci6n con el propietario.

Propietario: Conserve Ias instrucciones de instalaci6n para referencia futura.

Guarde las instrucciones de instalaci6n para tenedas a disposici6n del inspector de electdcidad local.

9760175