IMPORTANT SAFETY INSTRUCTIONS --Readallinstructions before usingthiscleaner.

When using any electri_l appliance, basic precautions should always be followed, including the following:

WARNING -To reduce the risk of fire, electric shock, or injury:

1. Do not leave cleaner when plugged into electrical outlet. Unplug from outlet when not in use and before servicing.

2. WARNING" TO AVOID ELECTRIC SHOCK, DO NOT EXPOSE TO RAIN -- STORE INDOORS.

3. WARNING: DO NOT REMOVE GROUNDING PRONG FROM POWER CORD PLUG. Connect to a properfy

grounded outlet ONLY. See Grounding Instructions.

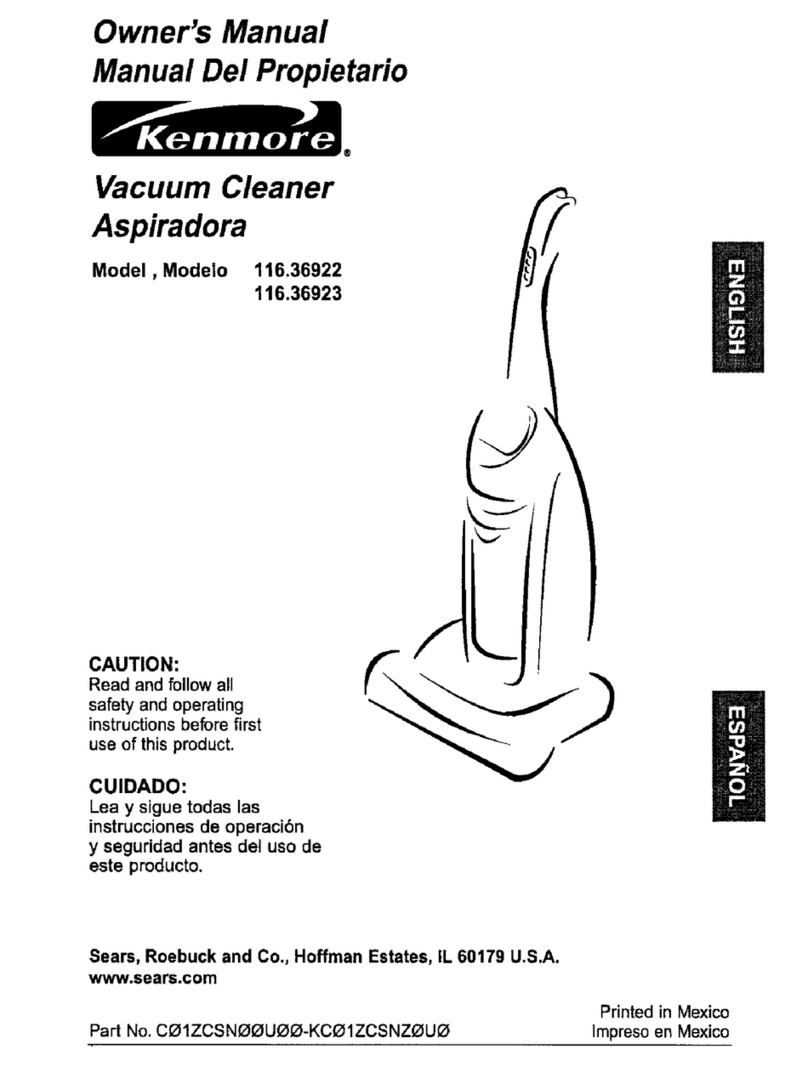

GROUNDING iNSTRUCTIONS:

Thisvacuumcleanermustbegrounded.Ifitshouldrnal[uncf_0nor

breakdown,groundingprovidesapathof lea,stresistancefor

electxicalcurrentton_:lucetheriskofelectricshock.Thisvacuum

cleanerisequipl:_lwitha cordhavinganequipment-grounding

conductorandgroundingi_ug.The plugmustbe pluggedintoan

appropdareoutletthatispmberlyinstalledandgroundedinaccor-

dancewi_ alllocalocdesandordinances.

WARNING:improperconnectionoftheequiprrent<jmuntlingcon-

ductorcanresultina riskofelecl_icshock.CheckwithaquaJified

electddanorservicepersonifyouareindoubtastowhaler the

0utietispmperlygrounded.DONOTmodifytheplugprovidedwith

thevacuumcleaner-- ifitwillnotlittheoutlet,haveaproperou_et

installedbyaqualifiedalectridan+

ThisVACUUmcleanerisforu_=ona nominal120-v01tcircuit,And

hasagroundedplug(seeIigureA).Atemporaryadapter(seetigure

B)maybeusedtoconnecthis plugtoa 2-polereceptacle(see

figure13)ifaprobedygroundedoutletisnotavailable,Thetempo-

raryadaptershouldbeusedonlyuntilaproperlygroundedoutlet(sse

figureA) can be installedbya qualifiedelectrician.The tab for

gmundlngscrew(seefigureB)extendingfromthe adaptermustbe

connectedtoapermanentgroundsuchasapmperiygroundedoutlet

boxcover.Whenevertheadap_risinuse,itmustbeheldinplace

byametalscrew(seeRgurea),

GROUNDED GROUNOED

PLUG OUTLET

Fiqure A

ADAPTER

I sca

TABFOR

GROUNDING 2-POLE

SCREW RECEPTACLE

Figure B

4. D_S_NNE_T P_WER C_RD FR_M ELECTR_AL _UTLET bef_re the recov_ryt_nk isemptied_the s_uti_n tank

is refilled, or the cleaner is serviced in any way,

5, DO NOT store this cleaner in an area which may reach freezing temperatures. Should this occur, DO NOT operate

this cleaner until ithas been at room temperature for at least two (2) hours.

6. DO NOT use any cleaning solution or chemicals otherthan those discussed inthis manual.

7. For maximum efficiency, empty container frequently and keep inside of hose, wands, nozzle and container clean.

8. DO NOT overwet carpet or upholstery. If three or more cleaning strokes are required, let the carpet or upholstery

material dry and then repeat cleaning process.

9. D_n_ta___wchi_drent__peretec_eaner_n_rsh_uidtheyp_aywithc_eaneresat_y_C__seattenti_nisneceasarywhen

used around or near children.

10, Use this cleaner ONLY for its intended use as described in this manual. Use only the attachments recommended in

this manual.

11. Always turn cleaner OFF when connecting or disconnectingthe Spraymate motorized nozzle.

12. Do not use with damaged cord or plug. Ifcleaner is not workingproperly, has been dropped, damaged, left outdoors,

or dropped into water, return itto a Sears Service Center.

13. Do not pull or carry by cord, nor use cord as a handle, norclose a door on cord, nor pull cord around sharp edges or

comers. Do not run cleaner over cord. Keep away from heated surfaces.

14. Do not unplug from electrical outlet by pulling on the cord. To unplug, grasp the plug, not the cord. and pull.

15. Do not handle plug or cleaner with wet hands.

16. Do not put any objects inventilation openings. Do not use with any opening blocked; keep openings free of dust, lint,

hair, and anything that may reduce air flow.

17. Keep hair, loose clothing, fingers, and all parts ofthe body away from openings and moving parts.

18. NEVER vacuum materials such as hot coals, cigareffe butts, matches, etc.

!9. When "dry" vacuuming do not us_ without filter in p_aca.

20. Turn off all controls before unphl_.;ing.

21. Use extra care when using on stairs.

22. Do not use to pick up flammable or combustible liquidssuch as gasoline or use in areas where such liquids may be

present_ -- SAV E.THESE iNSTRUCTIONS --