Shoebox Heat Pump Operational Manual Version 1

Page 2 of 20

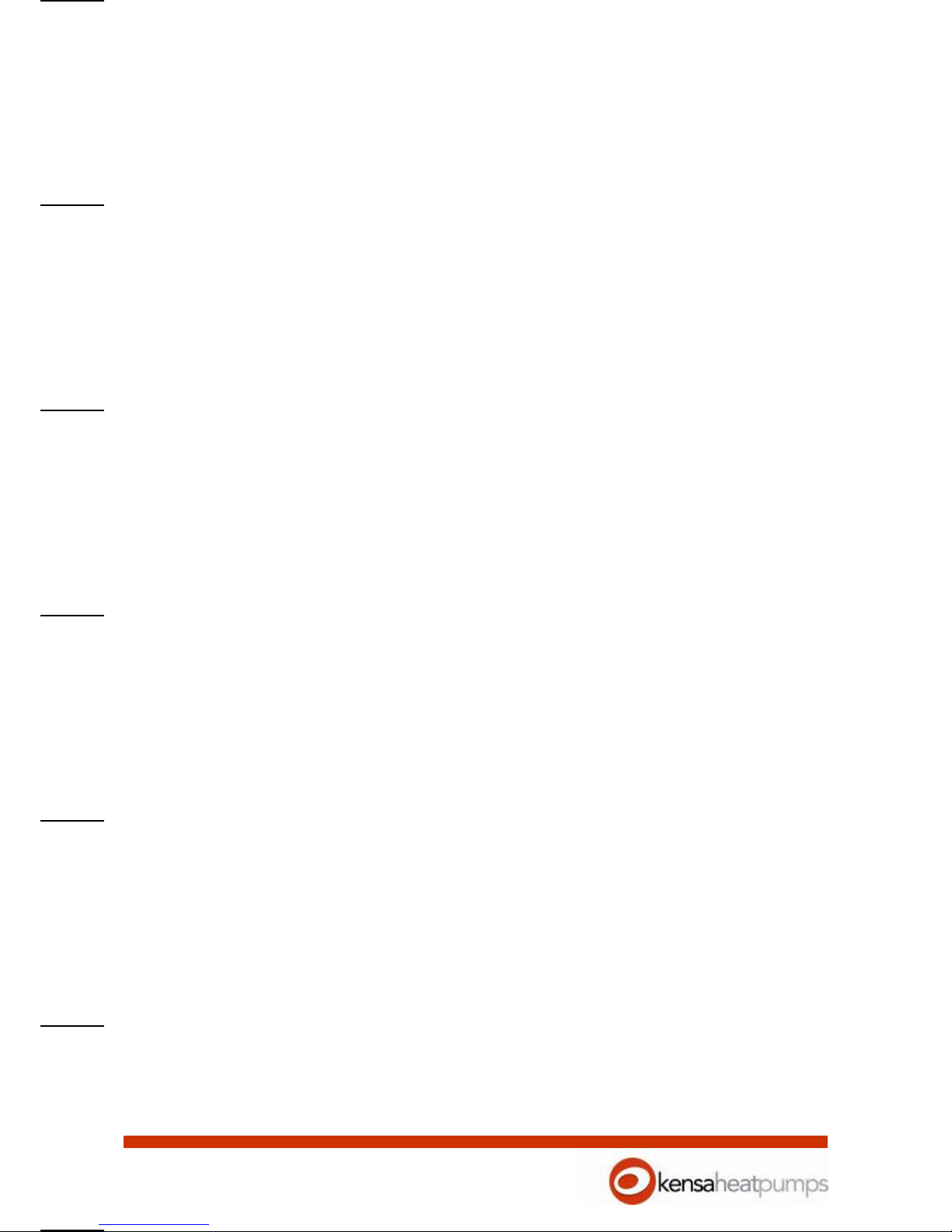

Contents Page

Section Description Page

1....................... Introduction.................................................................................. 3

2....................... Sa ety In ormation ....................................................................... 4

2.1........................... Disposal/Decommissioning..................................................................................... 4

2.2........................... Returning Products ............................. ................................................................... 4

3....................... General Product In ormation ....................................................... 5

3.1........................... ensa Engineering .......................... ....................................................................... 5

3.2........................... Product Description ................................................................................................ 5

3.3........................... ensa Shoebox Technical Details ........................................................................... 9

4....................... Operational Instructions .............................................................. 10

4.1........................... Maximising the efficiency of the heat pump .......................................................... 10

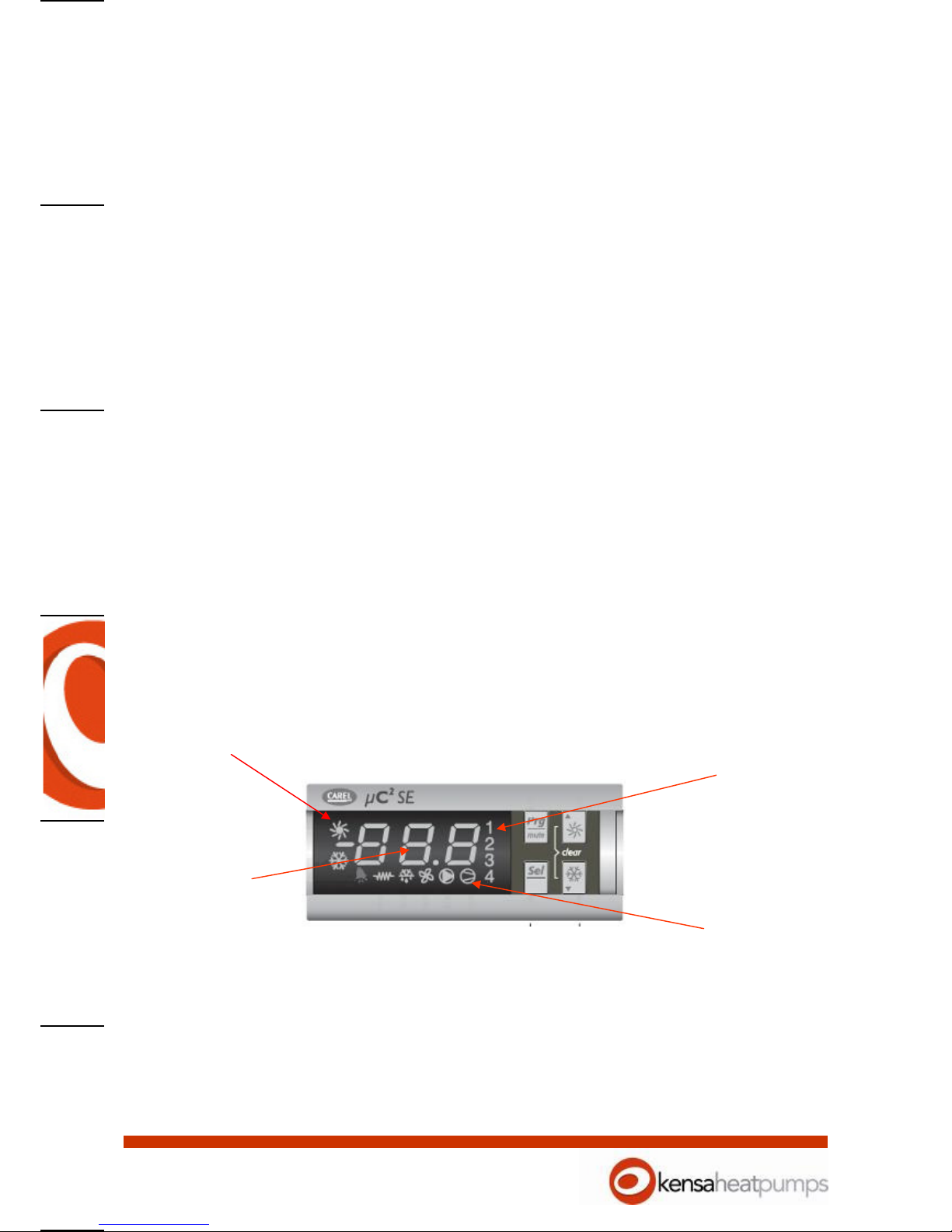

4.2........................... Display .................................................................................................................... 10

4.2.1........................ To read flow temperatures and refrigerant pressures ........................................... 12

4.2.2........................ To change the heat pump return flow temperatures ............................................ 12

4.3........................... DHW Production ..................................................................................................... 12

4.4........................... Maintenance .......................................................................................................... 13

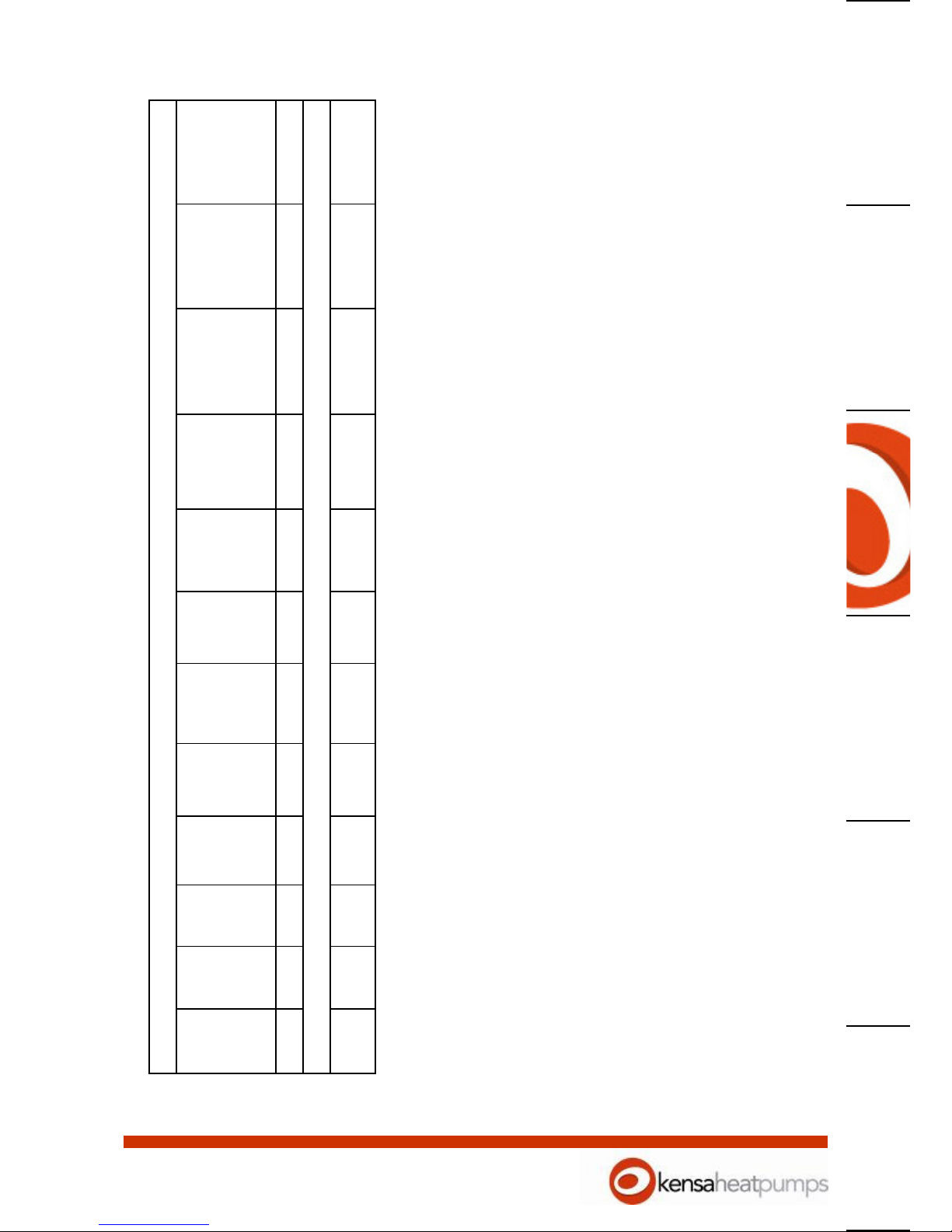

5....................... Fault inding ................................................................................. 14

6....................... Complaint Procedure ................................................................... 15

7....................... Warranty...................................................................................... 16

7.1........................... Terms and Conditions............................................................................................. 16

7.1.1........................ Persons covered by the Warranty........................................................................... 16

7.1.2........................ Validity period of the Warranty.............................................................................. 16

7.1.3........................ Scope....................................................................................................................... 16

7.1.4........................ General exceptions ................................................................................................. 16

7.1.5........................ Care of Duty ............................................................................................................ 17

7.1.6........................ In the event of Damage .......................................................................................... 17

7.1.7........................ Replacement Parts.................................................................................................. 17

Safety information

General product information

Operational Instructions Fault Finding Warranty Introduction