Kenwood D40-1132-05 User manual

Other Kenwood Car Receiver manuals

Kenwood

Kenwood DPX-5200BT User manual

Kenwood

Kenwood KCA-R71FM User manual

Kenwood

Kenwood KRC-265L User manual

Kenwood

Kenwood KRC-852D User manual

Kenwood

Kenwood KDC-X597 User manual

Kenwood

Kenwood KDC-PSW9531 User manual

Kenwood

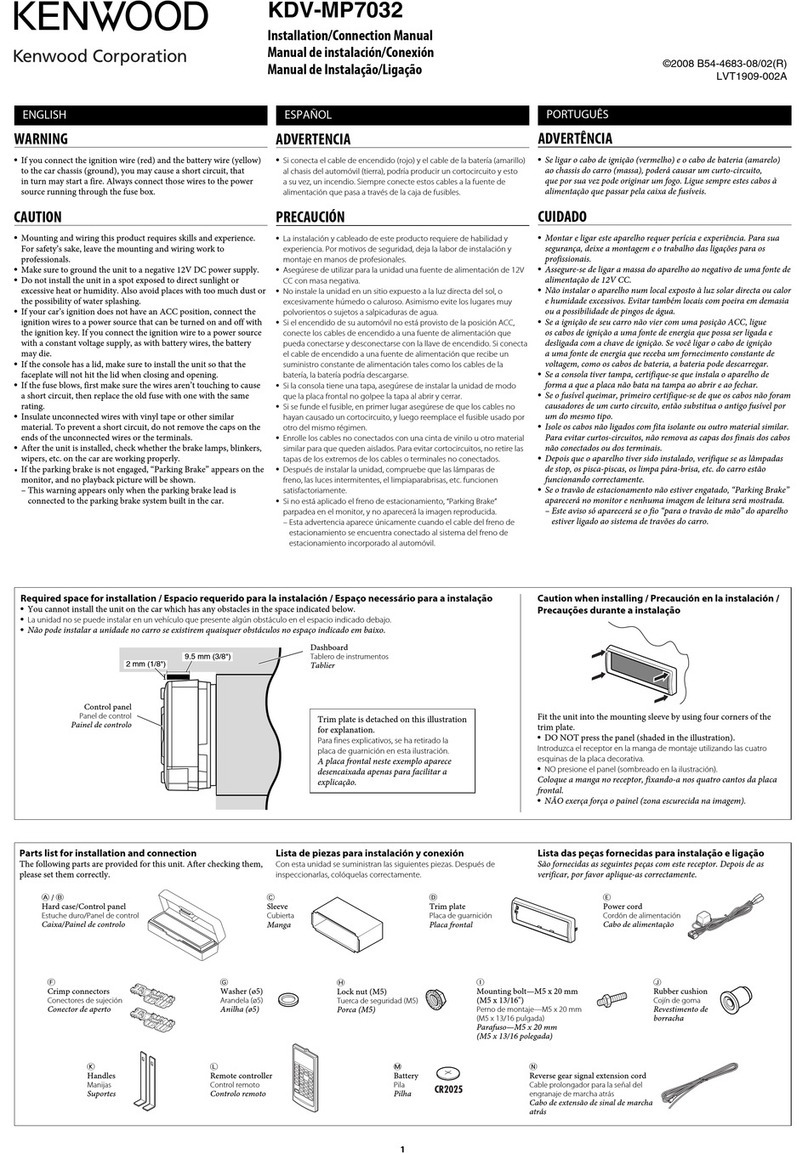

Kenwood KDV-MP7032 Guide

Kenwood

Kenwood KDC-757 User manual

Kenwood

Kenwood KDC-265U User manual

Kenwood

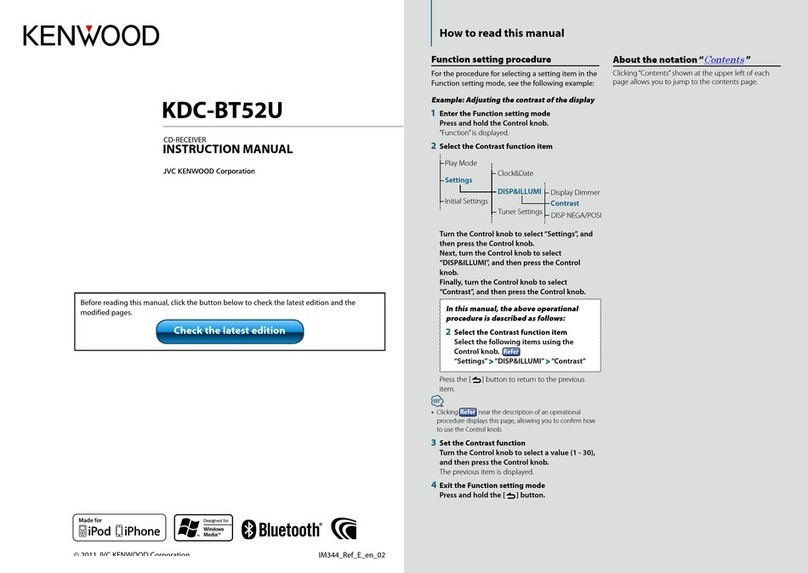

Kenwood KDC-BT52U User manual

Kenwood

Kenwood KDC-W237AY User manual

Kenwood

Kenwood KDC-BT370U User manual

Kenwood

Kenwood KDC-BT765HD User manual

Kenwood

Kenwood KRC-356D User manual

Kenwood

Kenwood KDC-1032 User manual

Kenwood

Kenwood KDC-220UI User manual

Kenwood

Kenwood Z920DVD User manual

Kenwood

Kenwood DPX308U User manual

Kenwood

Kenwood KDC-138 User manual

Kenwood

Kenwood KRC-365 User manual