28

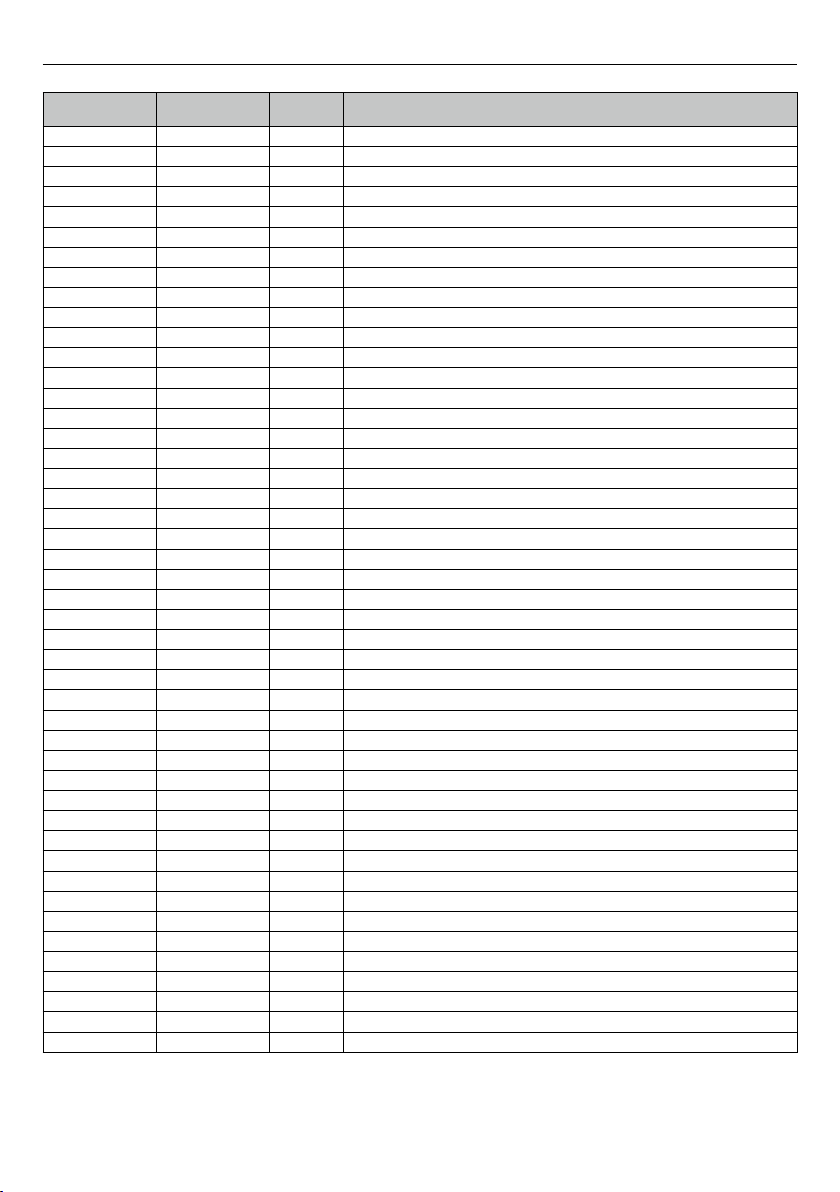

8. Spare parts list CATTLE

Reference Art. No. Amount Description

1 + 2 1Shearing blade replacement depends on application, ask your local retailer!

3 CR603 2 Screw for bottom cutter

4 CR604 1 Blade

5 CR605 2 Shaft screw for blades

6 CR606 6 Blade spring leaf

7 CR607 2 Spacer plate for blade spring

8 CR608 1 Spur gear wheel (28 teeth) with shaft

9 CR609 1 Eccentric square blade block

10 CR610 1 Shearing head housing with bush

11 CR611 1 Countersunk screw for shaft, M3x8 mm

12 CR617 2 Screw for blades, rear, M5x12 mm

13 CR616 1 Spring bridge

14 CR613 1 Adjusting screw with plug

15 CR615 1 Screw for spring bridge

16 CR624 1 Bush, large, 12x13.5

17 CR625 1 Bush, small, 6x10

18 CR626 1 Sleeve 14x18

3-18 18930 1 Shearing head complete, without cutter

13-15 CR627 1 Regulating screw replacement set

22 CR618 2 Screw for shearing head fastening

23 CR623 2 Carbon brush with spring

24 CO602 1 Anchor complete with bearing for 400 W motor

25 CO603 1 Stator for 400 W motor

26 CO605 1 Carbon brush holder set, left+right

27 CO607 2 O ring for anchor ball bearing

28 CO608 1 Mains connecting cable with plug

28 CO699 1 Mains connecting cable with plug, English

29 CO609 1 Mains unit switch

30 CO610 1 400W motor safety switch

31 CO611 1 Suppression capacitor

32 CO612 1 Cord

33 CO640 1 Motor housing, two-part

34 CO614 4 Screw 4x12 for gearing

35 CO615 6 Housing screw 4x20

36 CO616 1 Carrier loop

37 CO601 1 Gear 11/32 teeth for 400 W motor

37 CO622 1 Plastic cog wheel, 32 teeth for CO601

23-37 CR620 1 400 W drive motor complete

23-37 CO621 1 400 W drive motor complete, English

38 CR621 1 Air filter, right

39 CR622 1 Air filter, left

without illu. 1850488 1 Shearing machine oil constanta 100 ml

without illu. CR699 1 Operating instructions, Beef + Horse, DIN A5

without illu. CO600 1 Plastic case, incl. insert

without illu. 18946 1 TX20 screwdriver for Philips screw

without illu. 18945 1 Screwdriver for SM cutter

See separate spare parts drawing!