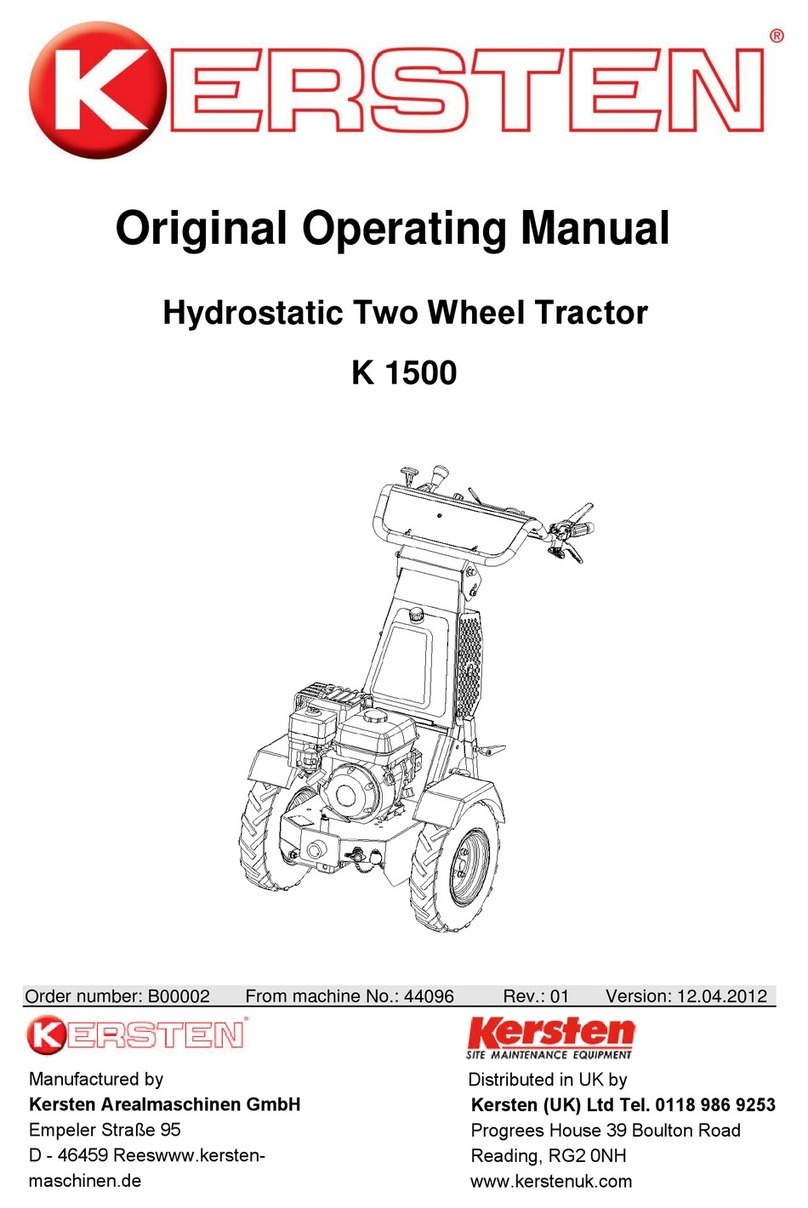

Kersten B00001 User manual

1

Original

Operating Instructions

Hydrostatic Two Wheel Tractor UBS Master

Order number: B00001 From machine No: 43470 R01 Stand: 03.01.2012

Manufactures by

Kersten Arealmaschinen GmbH

Empeler Straße 95

D - 46459 Rees

www.kersten-maschinen.de

Distributed in UK by

Kersten (UK) Ltd Tel. 0118 986 9253

Progrees House 39 Boulton Road

Reading, RG2 0NH

www.kerstenuk.com - [email protected]

2

TABLE OF CONTENTS

1

LETTER ..................................................................................................................................3

2

ABOUT THIS INSTRUCTION MANUAL .................................................................................4

2.1

BEFORE COMMISSIONING .................................................................................................................... 4

2.2

NOTES ABOUT THIS MANUAL ............................................................................................................... 4

3

SAFETY INSTRUCTIONS FOR HYDROSTATIC SINGLE TOWERS .....................................5

3.1

INTENDED USE ....................................................................................................................................... 5

3.2

GENERAL SAFETY AND ACCIDENT PREVENTION RULES................................................................. 5

3.3

USED PICTOGRAMS............................................................................................................................... 9

3.4

WARNINGS AND SAFETY INSTRUCTIONS FOR FILLED LEAD - ACID BATTERIES........................... 10

4

DISPOSAL ................................................................................................................................................ 11

5

WARRANTY.............................................................................................................................................. 11

6

RECOMMENDATIONS............................................................................................................................. 11

6.1

LUBRICANTS ...........................................................................................................................................11

6.2

FUELS ......................................................................................................................................................11

6.3

MAINTENANCE AND REPAIR.................................................................................................................11

6.4

INSTRUCTION FOR USE FOR STARTER BATTERIES..........................................................................12

7

THE OPERATION OF THE SELF-OPERATING WORKSTATION......................................................... 14

7.1

START THE MOTOR................................................................................................................................14

7.2

TROUBLESHOOTING AND SWITCHING ON THE SIDE DRIVE ............................................................14

7.3

STOPPING THE INTERNAL COMBUSTION ENGINE.............................................................................15

7.4

THE STEERING........................................................................................................................................16

7.5

HEIGHT ADJUSTMENT OF THE HANDWOOD.......................................................................................17

7.6

SIDE ADJUSTMENT OF THE HANDHOLM.............................................................................................17

8

ASSEMBLY............................................................................................................................................... 18

8.1

ASSEMBLY OF THE ATTACHMENT.......................................................................................................18

8.2

ASSEMBLY OF HAND PROTECTION.....................................................................................................19

8.3

MOUNTING OF THE GRID WHEELS ......................................................................................................20

9

GENERAL INFORMATION ON LOADING AND TRANSPORT INFORMATION................................... 21

10

MAINTENANCE........................................................................................................................................ 22

10.1

GENERAL MAINTENANCE INSTRUCTIONS..........................................................................................22

10.2

DAILY MAINTENANCE.............................................................................................................................22

10.3

MAINTENANCE AFTER 20 HOURS OF OPERATION OR LONGER SERVICE LIFE.............................23

10.4

MAINTENANCE AFTER 100 HOURS OF OPERATION ..........................................................................23

10.5

STORAGE ................................................................................................................................................23

10.6

CHECKING THE BELT TENSION VOLTAGE FROM THE SIDE DRIVE .................................................24

11

TECHNICAL SPECIFICATIONS .............................................................................................................. 25

12

WIRING PLAN SECURITY DEVICE ........................................................................................................ 27

13

MALFUNCTION AND THEIR REMEDY................................................................................................... 28

14

EC DECLARATION OF CONFORMITY................................................................................................... 31

3

Foreword

1

Introduction

Dear Customer,

Thank you for choosing a quality product from Kersten.

This product has been manufactured according to the most up-to-date production methods and extensive

quality assurance measures, because only when you are satisfied with your device, our goal isreached.

Before using this machine or implement for the first time, please read this manual thoroughly and thoroughly.

If you do not understand any of the information contained in this safety data sheet or the product-specific

installation or operating instructions, please contact your sales representative or the machine manufacturer

directly.

Keep this manual handy. Ifnecessary, you can read important information and instructions.

Have fun with your Kersten - device wishes you

Dipl.- Ing. (FH) Robert Bosch

Managing Director

4

Safety instructions

2

About this manual

The machine or implement is subject to technical progress. All information, illustrations and

technical data are up-to-date at the time of publication. Changes in the sense of technical progress

are reserved to the manufacturer at any time.

Therefore, no claims can be derived from the information and illustrations in this booklet.

2.1

Before commissioning

Since self-propelled implements and attachments can cause serious accidents or hazards if used

improperly, the first time the Kersten implement is commissioned, it must be instructed by competent

and authorized persons

absolutely necessary. The best way to familiarize yourself with its basic functions and its handling is

to choose a free and level terrain for your first trip

•

You reduce the risk of accidents on your part or third parties!

For further information and difficulties of any kind, please contact the dealer, importer or directly to

the manufacturer.

•

Be sure to read the safety instructions on the following pages!

•

Read the operating instructions before commissioning!

•

Pass on all safety instructions to other users!

2.2

Notes on this operating manual

•

Enumerations are marked with eye-catching points.

Example:

•

Text

•

Text

•

Instructions are marked according to the order in which they are to be executed.

Example:

1. Text

2. Text

5

Safety instructions

3

Safety instructions for hydrostatic towed tractors

The most important safety instructions in this manual cannot cover all possibilities. It goes without

saying that common sense and caution are factors that are not built into a machine but must be

brought by the person who uses and maintains the machine.

In order to keep the accident risk as low as possible, please observe the following subchapters.

3.1

Intended use

•

The towing vehicle as well as the devices approved by the manufacturer are suitable for the

respective usual or common use and work in the agriculture and forestry, as for example.

Green area and plant maintenance and built for winter service.

•

Any other use is considered improper use. The manufacturer is not liable for damage resulting

from this, the risk being solely borne by the operator.

•

Proper use also includes compliance with the operating, maintenance and service conditions

specified by the manufacturer.

•

The towing vehicle may only be used, maintained and repaired by persons familiar with it and

aware of the dangers.

•

The relevant accident prevention regulations as well as the other generally recognized safety

and occupational health rules must be observed.

•

Unauthorized modifications to the machine lead to the exclusion of liability of the manufacturer

for the resulting damage.

3.2

General safety and accident prevention regulations

3.2.1

Basic rules

•

In addition to the instructions in this operating manual, observe the general valid safety and

accident prevention regulations!

•

The towing vehicle may not be operated by persons under the age of 16, not even under the

supervision of a

Adults, be served! Children and adolescents should be instructed not to play with the device.

•

Only trained personnel or persons may use this machine!

•

When using public traffic routes, observe the relevant regulations!

•

The tiller is not approved for public transport.

•

The clothing of the user should be tight. Avoid loose-fitting clothing and wear sturdy

hoes or safety shoes!

•

Only work in good visibility and light conditions!

•

The attached warning and information signs provide important information for safe operation;

the attention serves your safety!

•

For transport on motor vehicles or trailers outside the area to be machined, the motor must be

switched off!

•

Be careful with rotating tools - safety distance!

•

Be careful with trailing tools. Wait for work on these until they stop completely!

•

There are crushing and shearing points on driven parts!

•

The transport of persons and objects is prohibited!

•

Driving behavior, steering and possibly braking capability as well as tilting behavior are

influenced by mounted or attached devices and load. For this reason, only implements approved

by the manufacturer may be used. The working speed must be adapted to the respective

conditions.

•

Do not make any changes to the engine's upper idle speed. Too high a speed increases the risk

of accidents.

•

Unauthorized conversions that endanger the operational safety of the machine are prohibited!

6

Safety instructions

3.2.2

Work and danger area

•

The user is responsible to third parties in the work area!

•

Staying in the danger area of the machine is prohibited!

•

Check the near range before starting up. Pay special attention to children and animals.

Ensure sufficient visibility!

•

Before starting work, remove foreign objects from the surface to be worked.

Pay attention to other foreign objects during work and eliminate them in good time.

•

When working in enclosed areas, the safety distance to the border must be maintained so as not

to damage the tool.

•

When working in the immediate vicinity of public roads and paths, these should not be

approached if possible, as there is a risk of injury to third parties due to flying objects.

•

When working on public roads and squares or in the immediate vicinity, warning and danger

signs should be set up in order to attract the attention of third parties.

3.2.3

Before starting work

•

Before starting work, please familiarize yourself with all the devices and actuators as well as their

function and make sure that all safety devices are properly installed and in the protective position!

It is too late during the work assignment!

•

Above all, learn how to stop the engine quickly and safely in an emergency

3.2.4

Starting the machine

•

When starting the motor, all drives must be switched off!

•

Do not run the engine indoors!

•

Do not step in front of the single-axle tractor or the implement to start the engine.

•

Do not use jumper fluids when using electric jump start (jumper cable). There is a danger of

explosion!

3.2.5

During operation

•

Never leave the operating position on the guide rail while driving!

•

Never adjust the operating handle while driving - risk of accident!

•

The transport of persons and objects is prohibited!

•

If, for example, the attachment has caught a foreign object and blocked it, stop the engine and

clean the attachment with a suitable tool! Always switch off the engine when handling or cleaning

the implement!

•

Do not leave the operating station until all tools of the attachment have come to a standstill!

•

In the event of damage to the self-propelled implement or attachment, stop the engine immediately

and have the damage repaired.

•

If the steering fails, stop the self-propelled implement immediately and stop the engine.

Have the fault rectified immediately.

•

If there is a risk of slipping on sloping ground, the implement carrier must be secured by an escort

with a pole or a rope. The escort must be located above the vehicle at a sufficient distance from

the work tools! For the helper, it is recommended to wear crampons.

•

If possible, always drive across (horizontally) to the slope!

•

Only drive on rough and dry ground on steep slopes! Moisture and rain increase the risk of slipping

out and slipping.

•

On steep slopes, lattice wheels or sprockets must be used to prevent the tractors from slipping

off.

•

In emergency situations, if, for example, the machine slips sideways in the slope, always release

the handles! You as an operator do not manage with their physical strength to prevent the

cultivators on slipping and are otherwise carried away.

7

Safety instructions

3.2.6

Leaving the machine

•

When stopping the machine, close the fuel cock (if present)!

•

By using wheel chocks or, if necessary, by applying the parking brake, secure the machine from rolling

away when leaving the vehicle.

•

Secure the device against unauthorized use!

•

Switch off the engine and, if present, remove the ignition key or the spark plug connector!

•

Never leave the machine unattended while the engine is still in operation!

3.2.7

Screw connections and tires

•

When working on the wheels, make sure that the device is safely parked and secured against rolling

away!

•

Regularly check nuts and bolts for tightness and retighten if necessary.

•

Repair work on the tires must only be carried out by qualified personnel and with suitable mounting

tools!

•

If the tire pressure is too high there is a risk of explosion!

•

Check the air pressure regularly!

3.2.8

Coupling and uncoupling attachments

•

Attach and remove attachments only when the engine is off and the PTO is off.

•

When replacing attachments and their parts, use suitable tools and

Wear gloves.

•

When mounting and dismounting, bring the required support equipment into the respective position

and ensure sufficient stability.

•

Secure the rear-mounted tow tractor with an attachment to prevent it from rolling (parking brake, wheel

chocks).

•

When attaching attachments, there is a risk of injury (crushing). Special care is necessary.

•

Attach implements according to regulations and fix in the prescribed places.

3.2.9

Maintenance, cleaning and repair work

•

Do not carry out maintenance and cleaning work on the running engine!

•

When working on the engine, always remove the spark plug connector.

•

If guards and working tools are subject to wear, they must be checked regularly and replaced if

necessary.

•

Damaged cutting tools must be replaced.

•

When replacing cutting tools, use suitable tools and wear protective gloves.

8

Safety instructions

•

Only use original spare parts from the manufacturer, as these comply with the technical

requirements and thus the risk of accidents is minimized!

•

Cleaning with the high-pressure cleaner should be carried out so that the water jet is not held

directly in bearings, turned parts, grease nipples, shaft seals, wheel hubs, etc. After each

cleaning with the high-pressure device, the lubrication points must be re-greased. In the case of

infringement, the right to guarantee expires!

•

Check the moving parts for ease of movement and regresses if necessary!

•

After maintenance and cleaning work, be sure to replace the guards and put them in the

protective position!

•

To avoid the risk of fire, keep the machine clean!

•

Regularly check nuts and bolts for tightness and retighten if necessary.

•

When carrying out maintenance, cleaning and repair work on the lifted device, always make

sure that it is protected by suitable support elements!

•

Before carrying out any repairs, make sure that the hydraulic system is depressurized, because

fluids under pressure can penetrate the skin and cause serious injuries! Therefore

See a doctor immediately - danger of infection!

•

Repairs may only be carried out by qualified personnel.

•

When working on the electrical system, always remove the earth strap from the battery!

•

Check the hydraulic hose lines for damage and aging at regular intervals and replace if

necessary.

•

When welding the tractor or mounted equipment, disconnect the battery.

•

Repairs such as welding, grinding, drilling, etc. must not be carried out on supporting and other

safety-related parts such as frames, axles, etc.!

3.2.10

Engine, fuel and oil

•

Before refueling, switch off the engine and remove the ignition key (if available)!

•

Do not top up with fuel and do not spill fuel (use a suitable refilling aid). If necessary, take up

spilled fuel immediately.

•

Dispose of oils, fuels and filters separately and properly!

•

When handling fuel, caution is required, increased risk of fire. Never refuel near open flames, hot

engine parts, and sparks when flying. Do not smoke when refueling!

3.2.11

Electrical system and battery

•

When working on the electrical system, always disconnect the battery (negative pole) (if

present).

•

Make sure the connection is correct - first positive pole and then negative pole!

•

Be careful with battery gases - Explosive!

•

Avoid sparks and open flame near batteries.

•

Take care when handling battery acid - corrosive!

•

Always provide the positive pole with the intended cover or terminal protection cap.

•

Caregivers of pacemakers must not touch the live parts of the ignition system while the engine is

running!

9

Safety instructions

3.3 Pictograms used

Explanation of the pictograms used:

Before commissioning read and observe the

operating instructions and safety instructions.

Switch off the engine and remove the spark plug

connector before carrying out any repair, maintenance

or cleaning work.

Never open or remove protective devices while the

engine is running!

Touch machine parts only when they have come to a

complete stop.

Danger from passing parts while the engine is running -

keep safety distance.

Follow the instructions in the technical manual.

Smudge!!

Safety instructions

10

3.4 Warnings and safety instructions for filled lead - acid batteries

•

Follow the instructions on the battery and in the operating instructions.

•

Use eye protection.

•

Keep children away from acid and battery.

Explosion hazard:

•

When charging batteries, a highly explosive bang mixture is produced, so please

note the following:

•

Fire, sparks, open light and smoking prohibited.

•

Avoid sparking when handling cables and electronic devices, as well as through electronic

charging.

•

Avoid short circuits

Burn Hazards:

•

Battery acid is highly corrosive, therefore:

•

Wear protective gloves and eye protection.

•

Do not tip the battery, acid can escape from the degassing openings.

First aid:

•

Acid splash in the eye; immediately rinse with clear water for several minutes. Then seek

medical attention immediately.

•

Acid splashes on the skin or clothing; Immediately neutralize with an acid converter or soapy

water and rinse with plenty of clear water.

•

In case of drunk acid, consult a doctor immediately.

Warnings:

•

Do not expose batteries to direct daylight unprotected.

•

Discharged batteries can freeze, therefore store frost-free.

Disposal:

•

Hand over used batteries at a collection point.

•

During transport, the following instructions for use must be observed.

•

Never dispose of old batteries in the household waste.

Safety instructions

11

4 Disposal

The equipment must be disposed of in accordance with local, state, or local regulations.

Depending on the material, you can dispose of the parts as residual waste, special waste or

recycling. The company Kersten Arealmaschinen GmbH assumes no disposal.

5 Warranty

The device is accompanied by a sales message, which among other things determines the time of

the start of the warranty period. When selling the device, please complete the sales message

completely and send it back to us within 14 days. If warranty claims are asserted without us having

a sales message, no warranty service will be provided.

Warranty claims should be submitted promptly, but no later than six weeks after the occurrence of

the damage, giving details of the purchase data, otherwise no warranty service will be provided.

Complaints must be confirmed by the company Kersten Arealmaschinen GmbH. Wear parts are

excluded from the warranty. Furthermore, the warranty expires due to improper operation, when

performing no or incorrect maintenance work, when using inadmissible equipment and when using

non-original spare parts.

6 Recommendations

6.1

Lubricants

For engine and gearbox, use the specified lubricants (see under "Technical data").

For "open" lubrication points or nipple points we recommend using bio lubricant oil or bio lubricant

grease. With the use of bio lubricant, you act ecologically correct, protect the environment and

promote the health of people, animals and plants.

6.2

Fuels

The built-up B & S or Honda engine can be easily operated with commercial unleaded normal and

premium gasoline and leaded premium gasoline.

Do not add oil to the gasoline.

If unleaded petrol is used for the environment, engines that are to be decommissioned for more than

30 days should have their fuel drained completely to avoid resinous residues in the carburetor, fuel

filter and tank, or to add fuel stabilizer to the fuel.

6.3

Maintenance and repair

Your dealer has trained mechanics who perform proper maintenance and repair. You should only

carry out major maintenance work and repairs yourself if you have the appropriate tools and

knowledge of machines and internal combustion engines.

Safety instructions

12

6.4

Instructions for Use for Starter Batteries

1.

Removal and installation of the battery

•

Before removing the battery, switch off the engine and all power consumers.

•

Avoid short circuits due to tools.

•

When removing, first disconnect the negative pole (-), then the positive pole (+).

•

Clean battery terminals and pole terminals and treat with acid-free grease.

•

Clean the footprint / support before installing the battery.

•

Tighten the battery firmly.

•

When installing, first connect positive pole (+), then negative pole (-).

•

Make sure that the pole terminals are secure.

•

Leave at least one gas outlet unlocked.

•

This also applies to the return transport of used batteries.

2.

External loading

•

Read and follow the operating instructions of the charger manufacturer!

•

Check electrolyte level before charging and level if necessary.

•

Disconnect the battery cable and remove the battery from the vehicle.

•

Ensure good room ventilation.

•

Use only suitable DC chargers.

•

Connect the positive pole (+) of the battery to the plus output of the charger.

Connect negative pole (-) accordingly.

•

Only switch on the charger after the battery has been connected and switch off

the charger after charging.

•

Charging current should be 1/10 Ah of battery capacity.

•

Interrupt the charge if the acid temperature exceeds 55 ˚C.

•

Battery is fully charged if charging voltage does not increase within 2 hours.

3.

Maintenance

•

Keep the battery clean and dry.

•

Do not use any improvers.

•

Do not open the battery.

•

If the starting power is insufficient, recharge the battery.

4.

Star Help

•

Use only standardized jump leads and observe their instructions for use.

•

Use only batteries of the same nominal voltage.

•

Switch off the engine from the helping vehicle.

•

First connect both positive terminals (+) with the red jumper cable. Then connect a

pole tongs to the negative pole (-) of the dispenser battery. Then clamp the second

pole on one of the bare spots of the needy single-axle tractor.

•

Start the helping vehicle, then max. The engine of the auxiliary towing vehicle max.

Start 15 seconds.

•

Disconnect the cable in reverse order.

Safety instructions

13

5.

Decommissioning

•

Store the battery in a cool place.

•

When decommissioning, disconnect the negative pole (-).

•

Regularly check the charge status of the battery and recharge if necessary.

14

Operation of the self-propelled implement

4

5

2

1L

1R

1

7 Operation of the self-propelled implement

3 3

Figure 7.1

7.1

Start the engine

•

To start the engine, the drive lever (Fig.7.1, item 1) must be in the horizontal position and the

PTO lever (Fig.7.1, item 2) must be in the "off" position.

If these are not in the position described above, the ignition of the engine is interrupted,

and the engine does not start.

•

During the starting process it is forbidden to operate the Deadman switch (Fig.7.1;

•

Observe the respective operating instructions of the engine manufacturer to start the engine

7.2

Starting and switching on the auxiliary drive

The best way to familiarize yourself with the basic functions of a self-propelled implement is to

choose a free and level terrain for your first trip.

•

Press the throttle lever (Fig.7.1, item 4) about 1/3.

•

Press the dead man switch (Fig.7.1, Pos.3) down and keep it pressed.

•

Make sure that nobody is in front of and behind the machine!

•

On both sides of the handlebar there is a driving lever (Fig.7.1, Pos.1L and 1R), which are

connected by a common pivot point and thus form a common driving lever (Fig.7.1, Pos.1). When

a drive lever is actuated, the opposite drive lever performs an opposite movement, so that the

operation of the drive lever is similar to a rocker.

•

For forward driving, the right-hand drive lever (Fig.7.1, item 1R) is pressed down by the right

thumb. The more the drive lever is pressed down, the faster the machine moves. In order to reduce

the speed or to stop the machine, push down the raised lever (Fig.7.1, item 1L) with your left

thumb.

•

If the individual drive levers (Fig.7.1, items 1L and 1R) are at the same height or in a horizontal

position, the machine is stationary.

15

Operation of the self-propelled implement

•

For the reverse drive, the left driving lever (Fig.7.1, item 1L) is pressed down by the left thumb.

The more the drive lever is pressed down, the faster the machine moves.

In order to reduce the speed or to stop the machine, push down the lever swung upwards (Fig.7.1,

item 1R) with your right thumb.

•

In order to select the direction of travel and the appropriate driving speed, the hands need not be

removed from the handles!

•

The force that needs to be applied with the thumb to operate the control lever can be adjusted to

the conditions of use. For light maintenance work, the brake resistor for the self-holding of the

driving lever may be smaller than, for example, when mowing on a slope. If the frictional resistance

is too small, then the driving lever retracts itself in the direction of the neutral position.

The lever to set the correct braking resistor is located in the center and below the control panel

(see Fig.7.1, item 5).

•

Use the throttle lever (Fig.7.1, item 4) to regulate the engine speed and thus also the driving

speed. Always try to drive with the lowest speed required, this protects material and the

environment.

•

The attachment machine is switched to "on" or "off" with the lever (Fig.7.1;

•

Switching on the implement is only permitted on a free or already worked area!

•

It is not permitted to switch on the implement outside the working area!

•

Never operate the attachment when children or animals are in the work area.

•

If, when turning on the attachment, you notice that the tool is not turning up and you hear a noise

from slipping V-belts, the attachment must be switched off immediately.

If the tool is engaged, the initial torque is too high. If possible, switch on the machine without load.

If necessary, check the tension of the tension spring on the Bowden cable.

7.3

Parking the internal combustion engine

•

Before switching off the combustion engine, make sure that the control lever (Fig.7.1, item 1) is in the

horizontal position and the PTO lever (Fig.7.1, item 2) is in the "off" position,

•

Move the throttle lever (Fig.7.1, item 6) to neutral and allow the engine to idle for approximately one-

half minute.

•

Set the engine off switch located on the internal combustion engine to "0".

•

Close the fuel tap.

•

Secure the towing vehicle against unauthorized use and, if necessary, remove the ignition key.

•

By using wheel chocks or if necessary by operating the parking brake, secure the device against

rolling away when leaving the vehicle.

Tip:

In case of prolonged downtime, do not stop the engine with the "Engine off switch", but close the

fuel cock and let the engine run until it comes to a standstill by itself. Thus, the carburetor is empty,

and no gumming can occur. This procedure must not be carried out in confined spaces, otherwise

there is danger of suffocation. Basically, pay attention to adequate ventilation!

16

Operation of the self-propelled implement

7.4

The steering

3

Figure 7.2

•

The implement is driven by two-wheel motors, which are controlled separately.

•

The single-wheel drive allows the wheels to rotate at different speeds and in different directions.

This makes it possible to drive very tight bends and, if necessary, to stop the machine quickly or

drive backwards.

•

As shown in Figure 7.2, a first steering lever (Pos. 1 or Pos. 3) and a second steering lever (Pos.

2 or Pos. 4) are arranged on the control panel on each handle.

•

If, for example, a left-hand drive is to be initiated, this can be done by actuating the first steering

lever (Fig.7.2, item 1) on the left handgrip (Fig.7.2, item 5). The more the first steering lever is

pulled through, the smaller the turning circle becomes, until finally the left wheel is blocked. The

right wheel is not affected in this steering maneuver and maintains its speed. If necessary, by

moving from the first steering lever to the second steering lever (Fig.7.2, item 2), the left wheel

can be moved in the reverse direction, whereby the turning circle can be reduced so that the motor

mower rotates about its own axis. There is a proportional behavior in both functions of the steering

levers. This means that the further the second steering lever is pulled through, the faster the left

wheel turns out of the blocked state in the opposite direction of travel.

•

When the two first steering levers (Fig.7.2, Pos.1 and Pos.3) are actuated at the same time, the

drive unit stops, while the second steering levers (Fig.7.2, Pos.2 and Pos.4) are in the reverse

direction at the same time emotional.

•

The control device with two steering levers on each side also constitutes a safety device, since it

is necessary to engage the two steering levers in a deliberate manner in order to change the

direction of rotation of the relevant wheel.

For sudden dangers moments:

•

In emergency situations, the operation of the two first steering levers (Fig.7.2, Pos.1 and Pos.3)

can be used to immediately stop the machine. The traction drive itself is switched off by the

subsequent actuation of the driving lever (Fig.7.1, item 1) in the horizontal position. Following this,

the two steering levers can be released.

•

Release the dead man switch (Fig.7.1, item 3). This shuts off the engine and brakes the wheels.

At maximum speed, the machine comes to a standstill after a few meters.

4

5

2

1

17

Operation of the self-propelled implement

7.5

Height adjustment of the hand rail

The hand rail is adjustable in inclination angle to ensure the operator an ergonomically optimal

working height.

1. Loosen the rotary knob (Fig.7.3, item 1).

2. Shake the handgrip until the toothed washers are free.

3. Bring the handrail to the desired height and insert it into the appropriate catch.

4. Retighten the twist grip (Fig.7.3; item 1).

1

Figure 7.3 Figure 7.4

Note:

The angle of inclination of the handrail is fixed by means of toothed discs (Fig.7.4, Pos.1). In order to

enable an adjustment, a toothed disk is axially displaceable. To permanently ensure that it can be

moved, it must be lubricated every 20 operating hours. The lubrication point (Fig.7.4, item 2) is located

in the direction of travel on the left below the control console.

7.6

Side adjustment of the hand rail

The handrail can be swiveled out of its normal position (middle position) by about 30˚ to the left

or to the right.

1. Pull up and hold the knob (Fig.7.5, item 1).

2. Swivel the handrail to the left or right to the desired position.

3. Release the knob (Fig.7.5, item 1) and move the handrail slightly to the left and right until the

locking pin engages.

1

Figure 7.5

18

Montage

8 Assembly

8.1

Assembly of the attachment

•

To mount an attachment, the attachment and attachment tube on the drive unit must be clean and

well-lubricated (see Figure 8.1).

•

The coupling of the attachment and the receiving tube of the drive unit must be at the same height

to allow them to be pushed together. For this purpose, parking supports are available on some

attachments, where the appropriate height can be adjusted.

•

When assembling, it is important to note that the clutch driver

(Plastic star) is located in one of the two coupling halves.

•

Pull up on the locking lever and lift up the locking lever.

•

If the attachment of the attachment can-not be pushed completely into the pick-up tube, then the

teeth of the two coupling halves may be opposite each other. By switching on the power take-off

and by slowly pulling on the starter cable of the engine, the drive shaft continues to rotate, allowing

the further drive in.

•

Lower the locking lever again and check that the locking pin is fully engaged.

Figure 8.1

Coupling

driver

Grease nipple

19

Montage

8.2

Assembly of the hand guard

The installation of the handguard is described in more detail below and illustrated in Figure 8.2.

1.

To install the left-hand guard, place the supplied drilling template (Fig. 8.2, item 1) on the hand spar

(Fig. 8.2, item 2) and drill two 6.5 mm holes.

2.

Screw on the left mounting bracket (Fig. 8.2, Pos. 3) with 2 M 6 x 20 screws, 2 body washers and

2 lock nuts.

3.

Fasten the hand guard with 2 M6 x 20 screws, 2 large washers and 2 lock nuts.

4.

Perform the same steps for mounting the right-hand guard.

1

3

2

Figure 8.2

Montage

20

8.3

Assembly of the lattice wheels

Figure 8.3

For the subsequent installation of the lattice wheel set, the hitch hubs (Fig.8.3, item 5) must first be

mounted on both sides of the self-propelled implement.

•

Raise the rear part of the self-propelled implement with appropriate tools until the drive wheels

are unloaded and free to move. The lifted machine is supported by a hard base - e.g. Squared

timbers - to be secured in such a way that unintentional falling is prevented.

•

Loosen the wheel nuts on both sides, remove the drive wheels and remove the existing wheel

bolts from the wheel hubs. These are replaced by the supplied wheel bolts M12 x 50.

•

First insert the drive wheel and then the supplied attachment hub of the mesh wheel onto the

existing wheel hub. Between the drive wheel and the attachment hub, the Limes rings (conical

washers) must be inserted so that the drive wheel is firmly centered on the wheel hub. The drive

hub and the attachment wheel are firmly screwed in using the stoppers provided. Here, the stop

nut is inserted into the 19`er nut and guided by means of a long extension through the mounting

hub to the wheel bolt.

•

The lattice wheels are mounted on soft ground immediately before use. Since the grids are larger

in diameter than the drive wheels, the machine or the drive wheels must be on a solid surface,

for. stand a wooden block.

•

The sprocket wheel is put on the hub and fixed by the driving plate (Fig.8.3; Pos.3).

•

Finally, secure the mesh wheel and drive plate with the thumbscrew (Fig.8.3; In order to avoid

unintentional loosening of the thumbscrew, there should be a spring washer (Fig.8.3; Pos.2) in

front of the thumbscrew.

Table of contents

Other Kersten Tractor manuals