89

Kice Industries, Inc. Kice Industries, Inc.

MAN-100-000-007 MAN-100-000-007091123091123

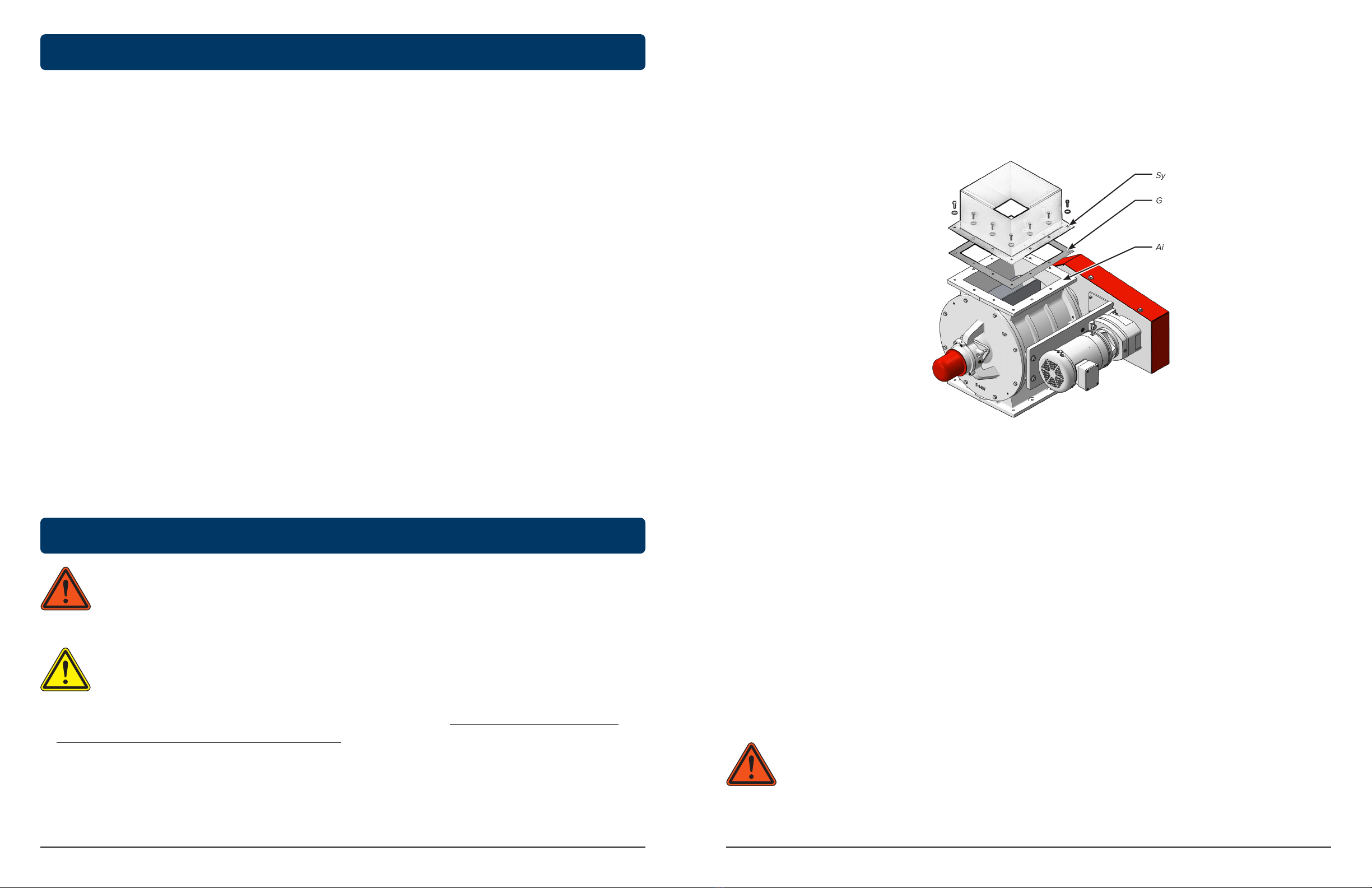

• All energy sources associated with the airlock must be locked and tagged out in compliance with 29 CFR 1910.147,

local enforcement authorities, OSHA, and facility safety practices, before removing any protective cover, guard, grate

or maintenance gate. Removal of transitions which expose hazards such as nip points of an airlock rotor also require

lockout and tagout precautions be employed.

• Do not attempt to install, connect power, operate or service an airlock without proper instruction and until you have

been thoroughly trained in its use by your employer.

• It is the owner’s and employer’s responsibility to adequately train each operator in the proper and safe use of airlocks.

Written safety programs and formal instruction are essential. All new employees must be made aware of company

policies, standard operating procedures (SOPs) and established health and safety procedures. Experienced employees

should receive refresher training for potential hazards and up to date training records should be maintained at the job

site.

• Assume at all times that power is “on”. Treat all conditions as live. This practice ensures a cautious approach that may

prevent an accident or injury.

• Before applying power to any equipment, make certain that all personnel are clear of the machine.

• Do not attempt to open, work on, clean or service an airlock until it has been locked and tagged out and the rotor has

come to a complete stop. It is especially important to verify the airlock cannot be started in environments in which

equipment is configured to be started remotely.

• Do not connect power to or operate an airlock unless all moving parts are covered and all covers, guards, grates, and

maintenance panels are in place and securely fastened. If an airlock is not equipped with a factory supplied chain

guard, make sure rotating members and moving parts are completely enclosed before connecting power and starting

operation.

• All protective covers, guards, grates, maintenance panels, switches and warning decals must be kept in place and in

good repair. Any airlock with a damaged, malfunctioning, defective, or missing protective device must be taken out of

service until the protective device can be repaired or replaced.

• Do not attempt to start an airlock when loaded.

• Do not abuse, overload, or misuse an airlock or attempt to operate the equipment if in need of service, lubrication,

maintenance or repair. Free outlet of the product must be guaranteed at all times. Blockage and severe damage may

result, or a dangerous situation may occur.

WARNING: All owners and operators should read this manual and be instructed in safe

operating and maintenance procedures before attempting to uncrate, install, operate, adjust

or service this equipment.

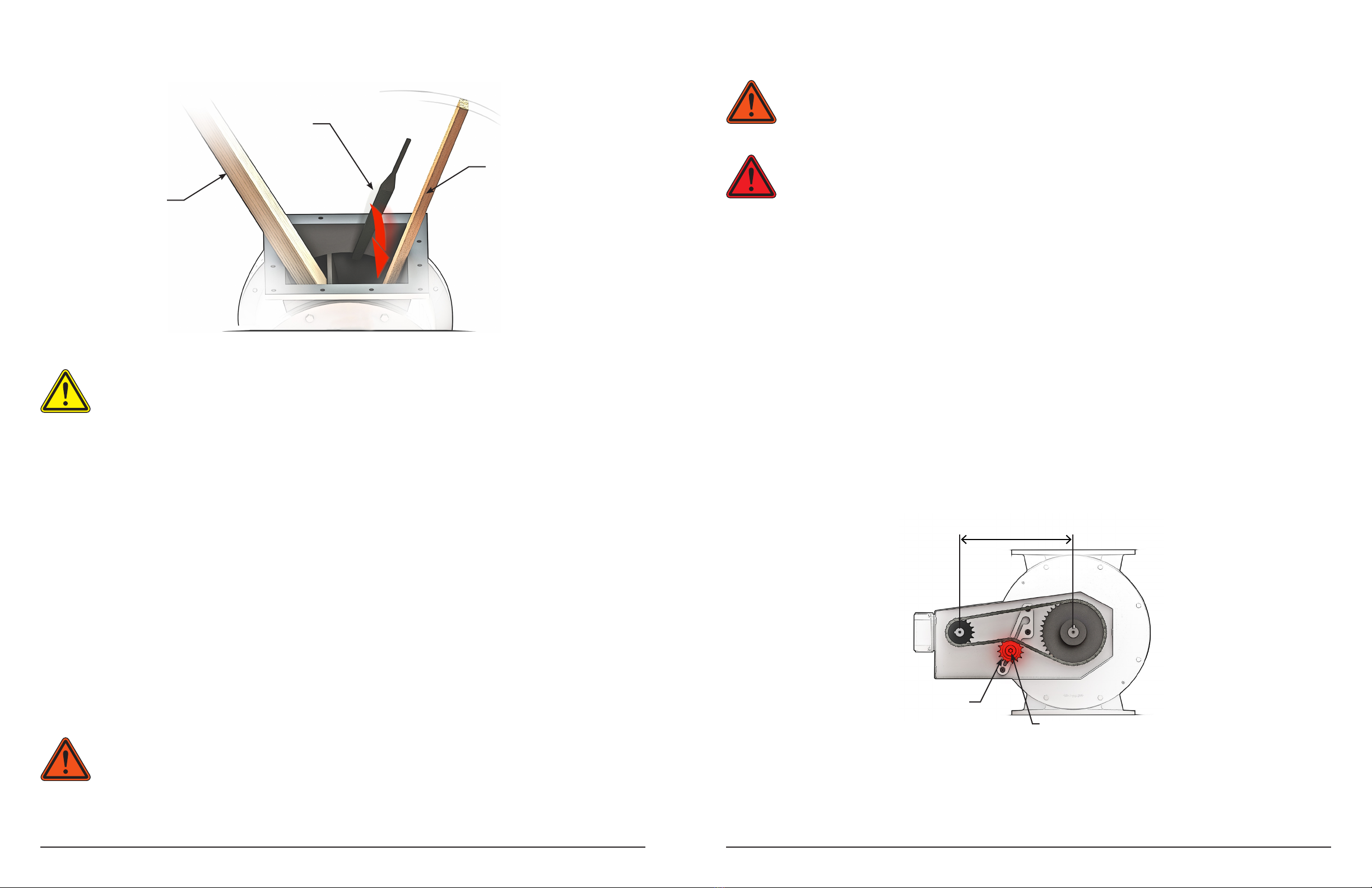

• Never place any part of your body under or near rotating members or moving parts of an airlock.

• Never allow any kind of metal or other foreign objects to enter an airlock.

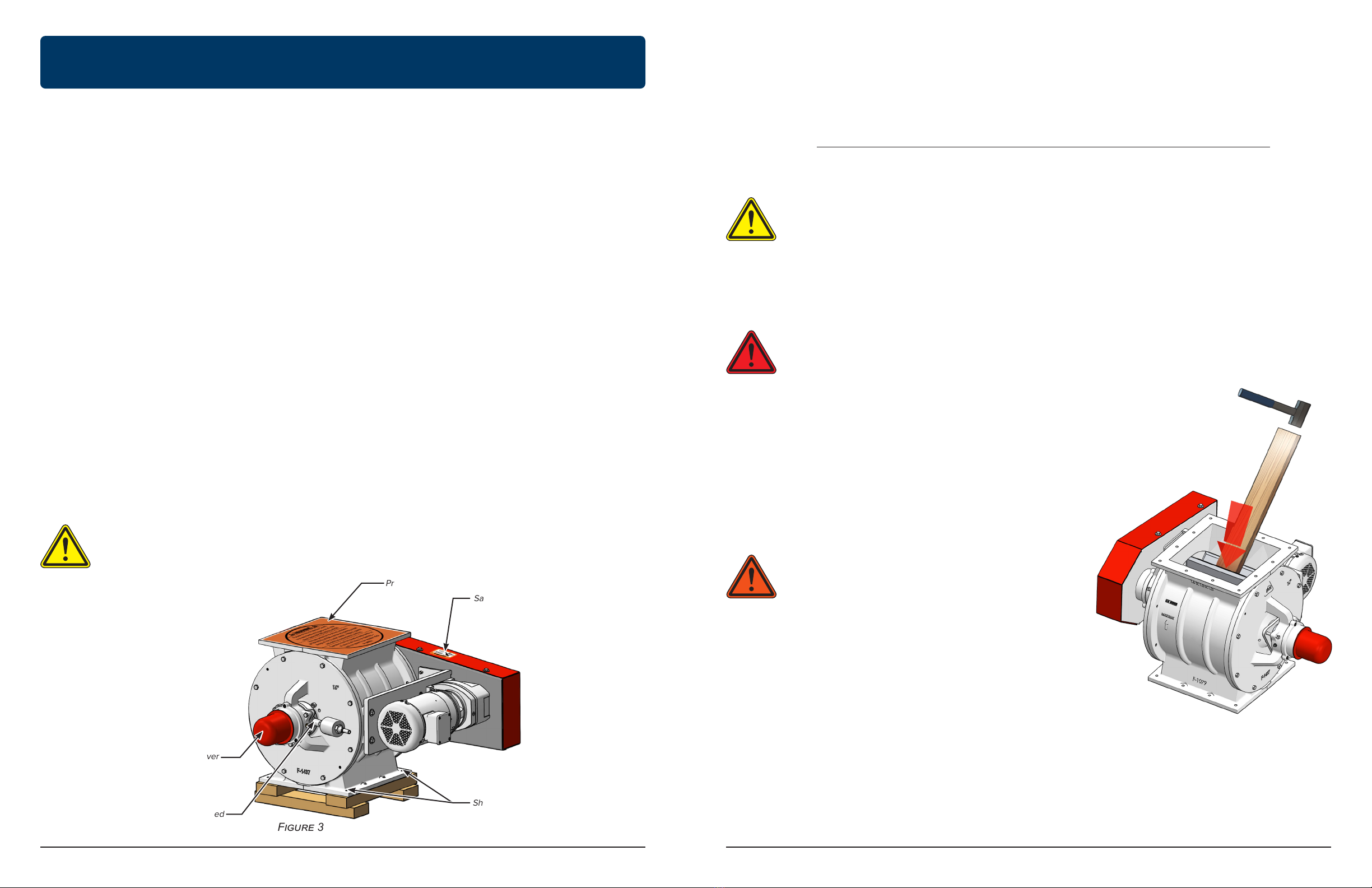

• The rotor of the airlock is built into a housing which has connection flanges for product inlet and product outlet. All

airlock inlet and discharge openings must be completely enclosed, or closed to an adequate length, to prevent human

access to the rotor when the airlock is operating. They must remain enclosed until POWER IS TURNED OFF AND

LOCKED OUT. Keep away from an airlock when it is running.

• Do not manually override or electrically bypass any protective device.

• High voltage and rotating parts can cause series or fatal injury. Only qualified, trained, and experienced personnel

should perform installation, operation, and maintenance of electrical machinery. Make sure the motor and frame of

each airlock is grounded in accordance with OSHA, National Electric Code, and all other applicable regulatory bodies,

including local codes and EN ISO 60204-1 as required for the classified area.

• Operator/installer must ensure that all piping and connections are laid away from equipment access routes and steps.

• If an airlock is equipped with a maintenance panel incorporating any Protective Interlocking Limit Switch (PLS), the PLS

must be interlocked with all electrical controls so that all motors or powered devices on the unit will be de-energized

if any protected cover, guard, grate, or maintenance panel is open or removed. Never attempt to manually override or

electrically bypass the PLS safety device. Interlock function of the PLS must be tested and logged daily by supervisory

personnel.

• Any device powered by air or hydraulic pressure must be equipped with a properly functioning Padlockable Manual

Pressure Lockout and Internal Pressure Relief Valve (PLV) capable of safely relieving motive pressure between the

isolation valve and device.

• Any airlocks used in the processing of combustible materials or in hazardous environments require evaluation by the

owner and regulatory bodies to determine appropriate airlock monitoring equipment, dust control, explosion protection

and electrical equipment enclosures. Do not use an airlock in hazardous environments unless properly equipped for

the hazard.

• Operate safely at all times. Use personal protective equipment (PPE) such as hard hats, helmets, gloves, earplugs,

protective eyewear, etcetera when and where appropriate. Keep PPE in good repair and accessible to aected

personnel.

• Keep the workplace clean and free of dirt and dust at all times. Do not attempt to work on slippery or unsafe surfaces,

ladders or work platforms when maintenance or repair work is being performed on an airlock.

• Do not use a ladder or work platform unless it is in good repair and rated for the load required to complete required

airlock service. Do not exceed maximum load ratings when installing or servicing an airlock.

• Never stand under any kind of hoists or lifting mechanisms whether or not it is loaded or in operation. Never stand

under or near an airlock or component when it is being lifted.

• All airlock lifting devices must be inspected by qualified personnel before each use. Do not use a lifting device to

transport an airlock. Never use a lifting device that is damaged, deteriorated or in need of repair.

• Special attention must be devoted to outside contractors engaged to enter and perform work on an airlock or in the

workplace. Special care must be exercised to ensure all such personnel are fully informed of potential hazards and

plant safety procedures. Special emphasis should be placed on the use of explosion proof electrical, cutting, or welding

tools where required.

• It is ultimately the operator’s responsibility to apply the above listed precautions and ensure proper airlock use,

maintenance and lubrication. Keep these instructions and list of warnings with your machine at all times.

• It cannot be assumed that every acceptable safety procedure is contained herein or that abnormal or unusual

circumstances may not warrant or require additional procedures.