8Eclipse ThermJet PCA, V2, Design Guide 206, 6/4/2010

NOTE: The stated operational characteristics only apply if

the described control circuits are followed. Use of different

control methods will result in unknown operational

performance characteristics. Use the control circuits

contained within this section or contact Eclipse for written,

approved alternatives.

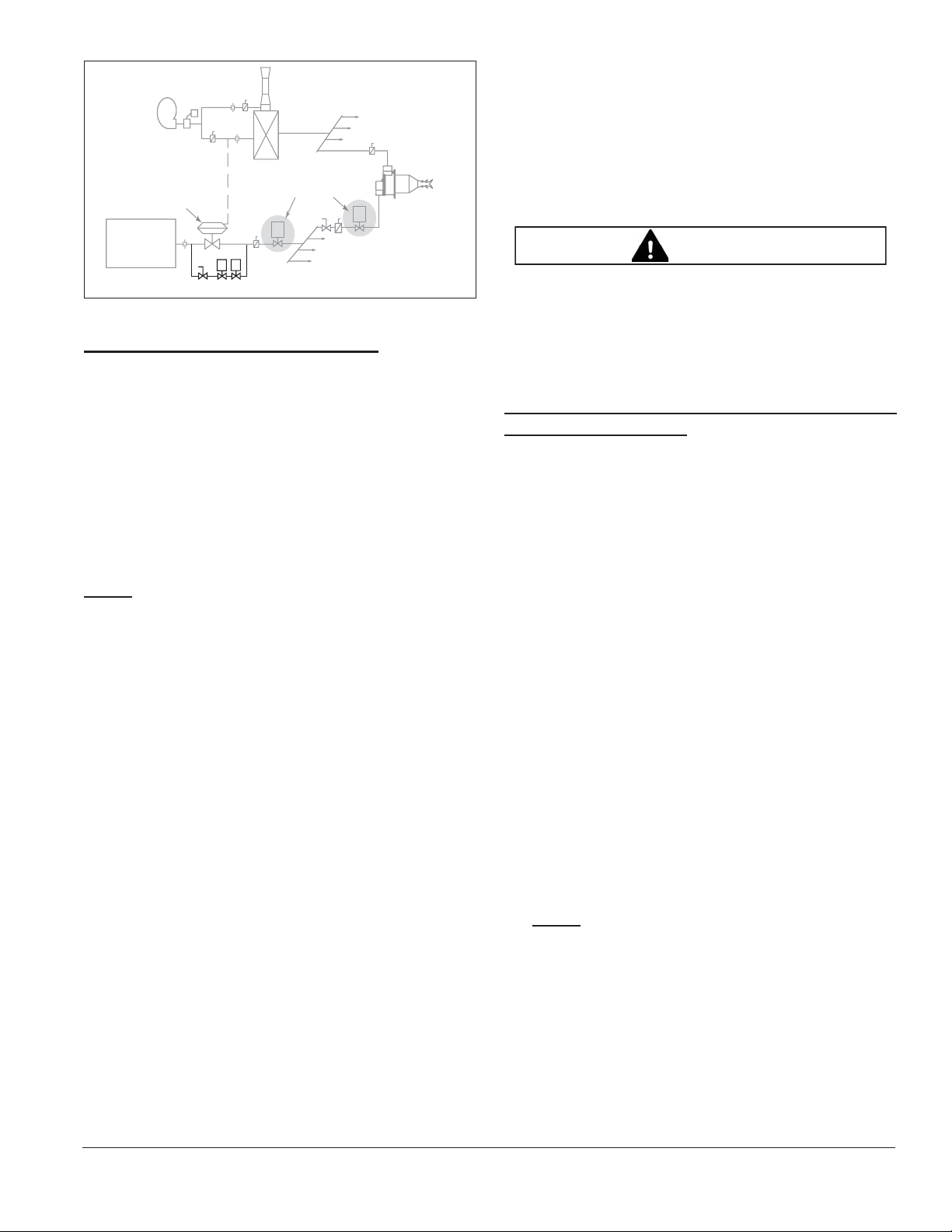

In Figure 3.2 there are schematics of these control

methods. The symbols in the schematics are explained in

the “Key to System Schematics” (see Appendix, page 13).

Automatic Gas Shut-Off by Burner or

Shut-Off by Zone

The automatic gas shut-off valve can be installed in two

operational modes:

Automatic gas shut-off by burner

If the flame monitoring system detects a failure, the

gas shut-off valves close the gas supply to the burner

that caused the failure.

Automatic gas shut-off by zone

If the flame monitoring system detects a failure, the

gas shut-off valves close the gas supply to all the

burners in the zone that caused the failure.

NOTE: All ThermJet PCA control schematics reflect a

single gas automatic shut-off valve. Each schematic

shows both operational modes. Only one is necessary.

This may be changed to conform to local safety and/or

insurance requirements (Refer to ThermJet Installation

Guide No. 206).

Modulating Gas & Air

On-ratio control or excess air @ low fire

A burner system with modulating control gives an input

that is in proportion with the demands of the process. ANY

input between high and low fire is possible.

1. Air

The control valve Xis in the air line. It can modulate

air flow to any position between low and high fire air.

2. Gas

The ratio regulator Yallows the on-ratio amount of

gas to go to the burner. Low fire gas is limited by the

ratio regulator Y. High fire gas is limited by the

manual butterfly valve Z.

NOTE: The ratio regulator can be biased to give excess

air at low fire.

NOTE: Do not use an adjustable limiting orifice (ALO) as

the high fire gas limiting valve Z. ALO’s require too much

pressure drop for use in a proportional system.

Step 3: Ignition System

For the ignition system use:

• 6,000 VAC transformer

• Full-wave spark transformer

• One transformer per burner

DO NOT USE:

• 10,000 VAC transformer

• Twin outlet transformer

• Distributor type transformer

• Half-wave transformer

It is recommended that low fire start be used. However,

ThermJet PCA burners are capable of direct spark ignition

anywhere within the specified ignition zone (see

Datasheets 206-1 through 206-13).

NOTE: You must follow the control circuits described in

the previous section, “Control Methodology,” to obtain

reliable ignition. Local safety and insurance require limits

on the maximum trial for ignition time. These time limits

vary from country to country.

The time it takes for a burner to ignite depends on:

• The distance between the gas shut-off valve and the

burner

• The air/gas ratio

• The gas flow at start conditions

It is possible to have the low fire too low to ignite within the

trial for ignition period. Under these circumstances you

must consider the following options:

• Start at higher input levels

• Resize and/or relocate the gas controls

• Use bypass start gas

Bypass Start Gas (Optional)

A bypass start gas circuit provides gas flow around zone

gas control valves during the trial for ignition period. This

should only be used if excess air is being used on low fire;

it should NOT be used with on-ratio low fire systems.

During the trial for ignition period, the solenoid valve in the

bypass line plus the automatic gas shut-off valve (either at

each burner or each zone) are opened. If a flame is

established, the bypass solenoid valve closes at the end

of the trial for ignition period. If a flame is not established,

then the bypass solenoid valve and the automatic gas

shut-off valve closes.