September 200283-KRS100-001 4

KRS-100 Nitrogen Releasing System

but bends ust be ade so that the tubing will not flatten

or kink. A single coil of tubing approxi ately 2-1/2 inches in

dia eter is desirable at each flare or co pression fitting.

The coil ay be neatly ade by wrapping the tubing around

any convenient cylindrical object of that dia eter.

When sliding the tubing through conduit the leading end of

the tube should first be cri ped and bent double so as to

provide a s ooth sliding surface and to prevent possible

foreign atter in the conduit fro entering the tubing. All

tubing fittings with pipe threads, as at the KRS-100 actua-

tor valve body, the pressure-operated actuator and other

accessory devices, shall be asse bled with Teflon tape

wrapped around the ale pipe threads.

All tubing should be blown out with air or nitrogen prior to

aking final connections. Table 1 su arizes the length

of tubing allowed per each KRS-100 cylinder.

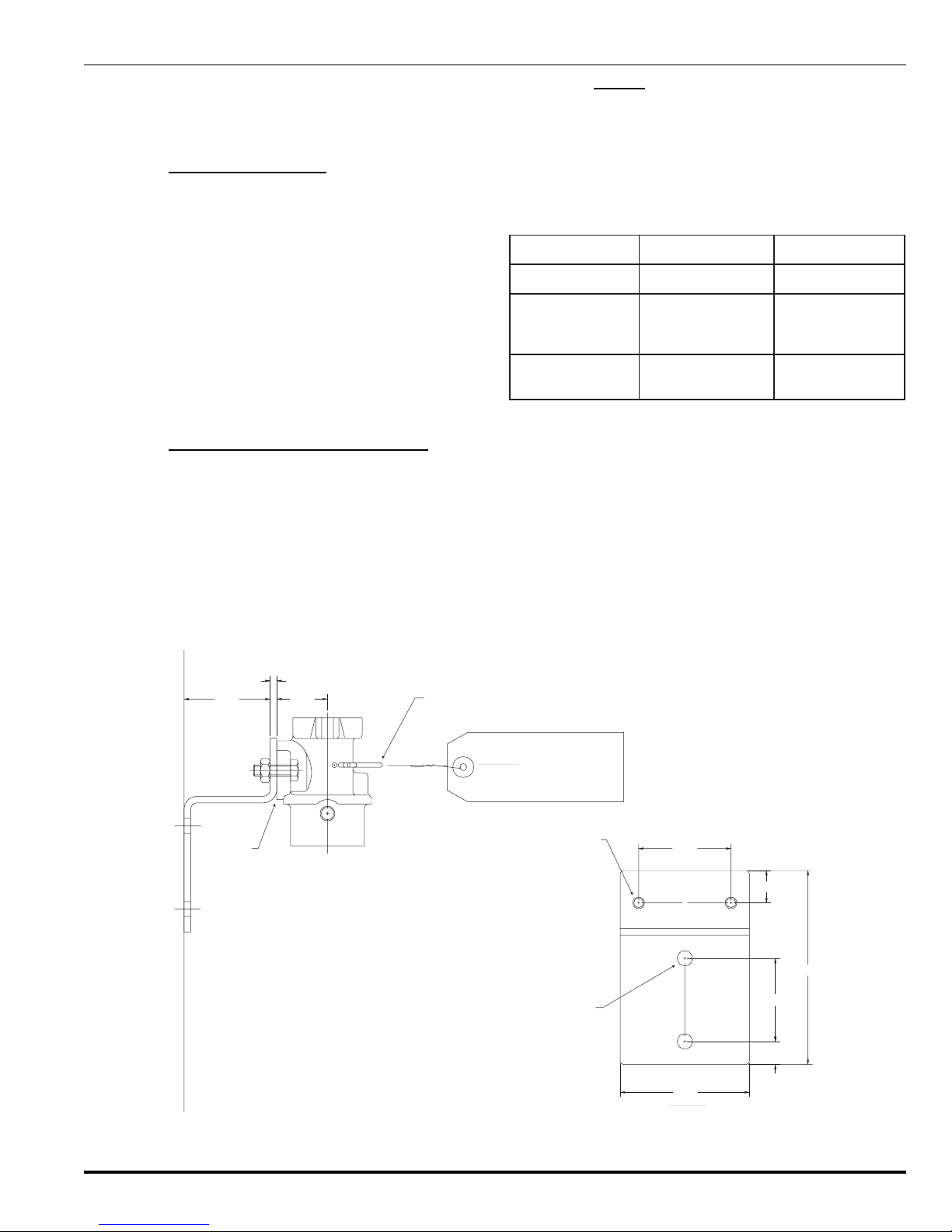

3-1.4 Co trol Head Mou ti g

(To Actuator Valve Assembly)

Note: The syste control head ust be ounted to the

KRS-100 actuator valve body using the ounting kit

(P/N 06-129706-001) supplied with the Actuator Valve

Asse bly (P/N 83-100010-001).

This kit contains a rubber gasket that ust be placed be-

tween the ating surfaces of the actuator body and the

control head housing. This kit also contains Teflon coated

bolts and nylon washers for fastening the actuator valve

asse bly to the control head housing.

Prior to ounting a control head on the KRS-100 actuator

valve asse bly ake certain of the following:

1. The control head is in the SET position. On echani-

cal installations the anual release lever should be

pushed up and the tensioning tool inserted in safety

hole in the housing. On electrical installations ake

certain the solenoid trigger holds the actuating lever.

The actuating ca arrow should be pointed away fro

the ratchet spool, (toward the SET position on face-

plate), and the release plunger should be flush or slightly

retracted within the control head body.

2. Ensure the safety pin is in place on the actuator valve

asse bly. See Figure 2.

3. Do not install the nitrogen cartridge at this ti e.

Note: Control Heads are shipped in the SET position with

cover off for ease of installation. There are

tensioning tools shipped with the echanical and

tande control heads to enable proper tension

setting on the cable. A tensioning tool ay be used

with the pneu atic control heads. There is no

tensioning tool per itted with the electrical control

heads. The plunger of the electric solenoid holds

the control head echanis in proper position for

the SET position.

4-1 SYSTEM CHECK-OUT

To de onstrate proper operation of the actuating syste

the following check-out is to be acco plished prior to i -

stalli g the itroge cyli der (P/N 83-100004-001).

4-1.1 For Co trol Head Operatio

1. Re ove the tensioning tool (when used) fro the safety

hole in the control head. If the syste is properly in-

stalled, the head should re ain in the SET position,

fully prepared for either auto atic or anual opera-

tion.

2. Re ove safety pin fro actuator valve asse bly.

3. All cables, with the exception of re ote pull cables,

should be in a taut condition if properly installed.

4. For fusible link check-out, cut the S hook farthest fro

the control head (ter inal link). The released tension

should per it the control head to operate, triggering

the releasing echanis .

5. Check to see that the actuating ca is in the operated

position and that the actuating ca (shaft arrow) has

rotated to the released position. All cables should be

slack, including re ote cable.

6. To check out electrical control heads, do the following:

Ensure that the actuating ca (shaft arrow) is turned

to the SET position. Energize the control head by ap-

plying heat directly to the ther ostats or operating the

panel.

7. Check that the control head triggering echanis has

released. Check that the actuating ca arrow has ro-

tated to the release position.

8. Check to see that the gas valve and/or electric shut-off

have operated. Slack in the cable is an indication, but

only the shut-off of gas and/or shut-off of electric cur-

rent to the hazard de onstrates that these units have

properly functioned.

9. Inspect all other aspects of syste operation, such as

da pers and door holders to see that the syste has

been installed properly.

10. After resetting the syste as outlined below, repeat

check-out by operating local and re ote anual con-

trols to assure their operation.

5-1 READYING THE SYSTEM

If all conditions have proven to be operational, place sys-

te in operation as follows:

1. If the fusible link syste is used, install a new S hook

in the detection line. If the electric syste is used, re-

place ents should not be required.

2. Reset the control head.

3. Re ove the control head tensioning tool when done,

and discard. Electric control heads do ot use

tensioning tools.