5

DG Operating Instructions

1 For Your Own Safety

1 For Your Own Safety

1.1 Intended Application

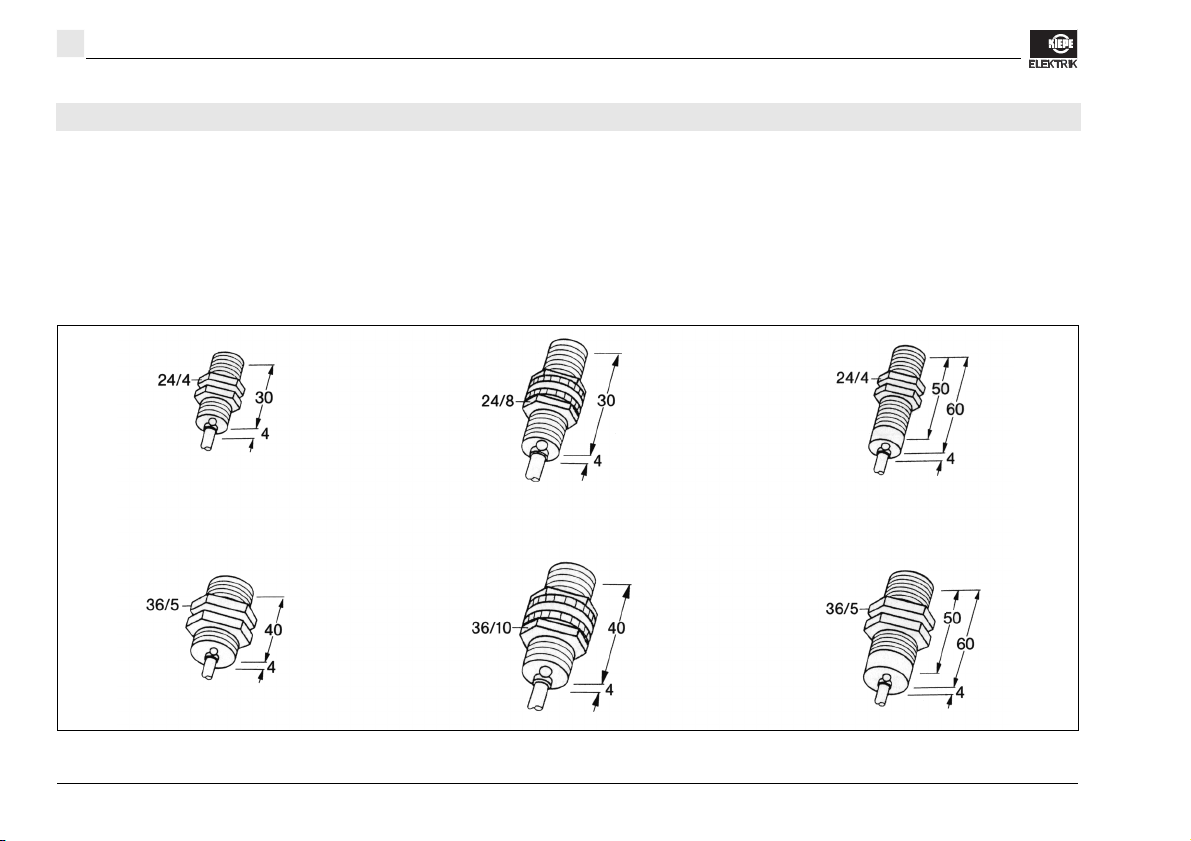

The pulse generators of the DG type series generate

pulses, the frequencies of which depend on the rotation-

al speed. The pulse generators are particularly suited for

application if high accuracy of operation, long service life

as well as wear and corrosion resistance are important.

The pulse generators meet the high requirements of the

relevant regulations.The device is intended for use in

stationary installations and in vehicles.

Applications other than specified and unauthorized mod-

ifications to the device or its components can lead to in-

jury to persons and damage to the device, for which the

manufacturer is not liable.

Make sure that the intended use is not impaired in any

way, even after unexpected outside influence on the de-

vice.

"Intended application" particularly means that any work

performed with or on the device is to be carried out in

accordance with these operating instructions. Only

skilled persons who are familiar with the Regulations

on the Prevention of Accidents as well as the other

generally accepted safety rules are allowed to work on

this device.

You protect yourself and prevent damage to the de-

vice when you apply the device as intended!

1.2 Symbols

Please pay particular attention to the text passages that

are marked with the following symbols:

Danger!

Information that has to be observed at all

events in order to protect the user from being

injured.

Attention!

Information that has to be observed in order

to prevent damage to the device.

Helpful additional information