7

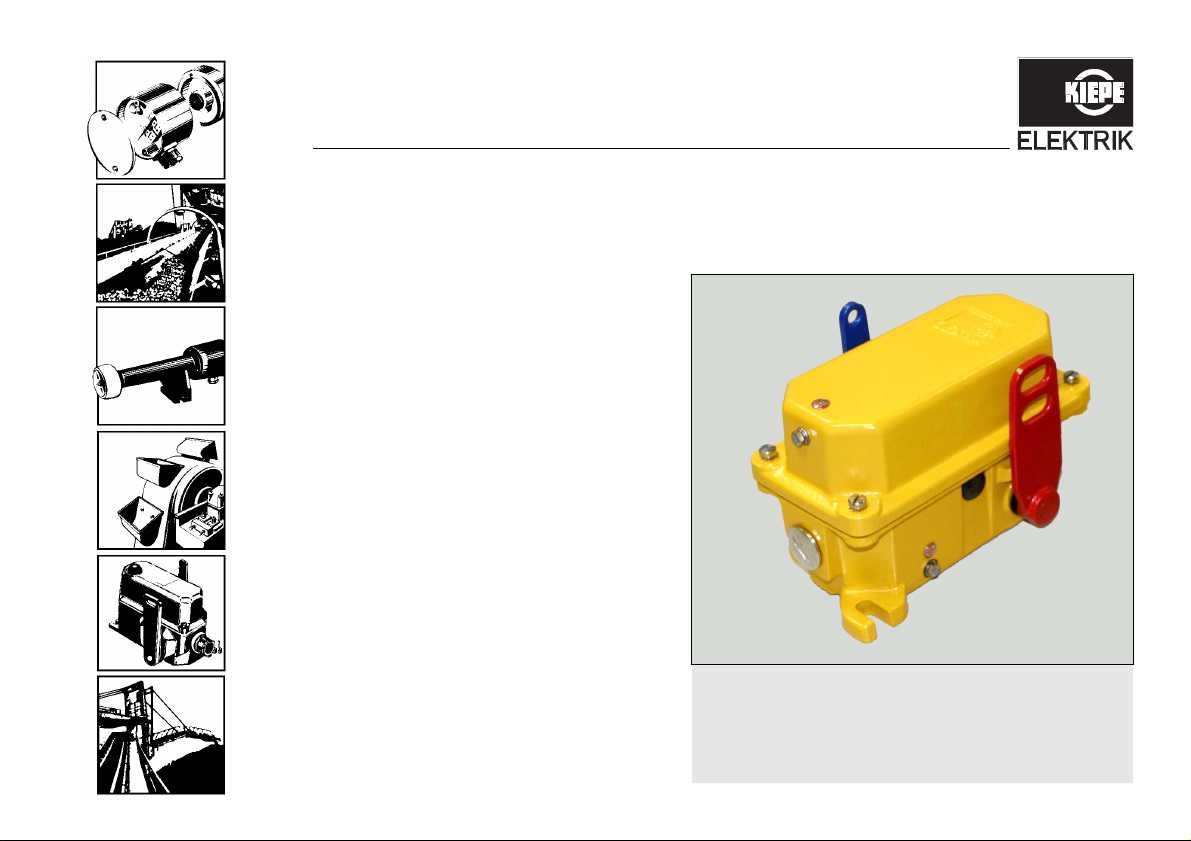

Operating Instructions SEG

1 Safety

1 Safety

1.1 Intended use

Pull-rope emergency stop switches, type SEG are used

as emergency stop devices actuated on both sides in

stationary conveyor systems in control circuits in accor-

dance with the safety requirements of DIN EN 620 and in

harmony with DIN EN ISO 13850. According to the BGIA

report 2/2008 "Functional safety of machine controls -

application of DIN EN ISO 13849" issued by the German

Social Accident Insurance (Deutsche Gesetzliche Unfall-

versicherung), the pull-rope emergency stop switches

can be used as emergency stop devices in safety control

circuits up to performance level PLe.

These operating instructions describe the intended use,

mechanical mounting/dismounting at the attachment

points for the pull-rope emergency stop switch SEG,

electrical connection and maintenance, repair, commis-

sioning and troubleshooting for the pull-rope emergency

stop switch SEG. These operating instructions do not

contain any information regarding the use and handling

of the pull-rope system or the control.

Improper use of the device and unauthorized changes to

the device and its components may result in injury and/or

damage, for which the manufacturer will not assume

any liability. Ensure that intended use cannot be im-

paired in any way, even by an unforeseen external influ-

ence on the device.

Die vorliegende Dokumentation ist als Teil des Produk-

tes zu betrachten und muss während der Lebensdauer

des Produktes behalten werden und dem jeweiligen Be-

sitzer/Benutzer zur Verfügung stehen. Die Dokumenta-

tion muss an jeden nachfolgenden Eigentümer des

Produktes weitergegeben werden.

Intended use includes in particular that you perform all

activities with and on the device with the aid of these op-

erating instructions.

Work on the device may be performed only by techni-

cians who have been authorized by the person respon-

sible for the safety of the system to perform the required

activities.

Qualified technicians are those who, on account of their

training, experience or instruction as well as their knowl-

edge of relevant standards, laws, provisions, accident

prevention regulations, generally acknowledged rules on

safety and operating conditions, are able to perform the

required activities and can identify and prevent potential

hazards. If the work requires specialized knowledge,

e. g. in electrical engineering, mechanics and pneumat-

ics, technicians must have the appropriate qualification.