5

Operating instructions HES and SEL

1 For your safety

CONFIDENTIAL

1 For your safety

1.1 Intended use

The belt misalignment switches HES and SEL are used

for monitoring the true running of continuous conveyors.

The switches serve to protect the belts from being dam-

aged or destroyed if the belt deviates from its designed

running line. The device is intended for use in stationary

installations and vehicles.

The documentation at hand is to be considered part of

the product and must be retained and be available to the

respective owner/user for the entire service life of the

product. The documentation must be passed on to each

subsequent owner of the product.

The manufacturer is not liable for personal injury and

property damage arising from non-intended use of the

device or unauthorized modifications to the device and

its components. Make sure that the intended use is not

impaired in any way even after unexpected outside influ-

ence on the device.

Intended use refers specifically to the operation of the

device in accordance with these operating instruc-

tions. Work on this device may only be carried out by

qualified personnel who are familiar with accident pre-

vention regulations as well as other generally recog-

nized safety regulations.

By using the equipment as intended, you protect

yourself and prevent damage to the equipment and

its components.

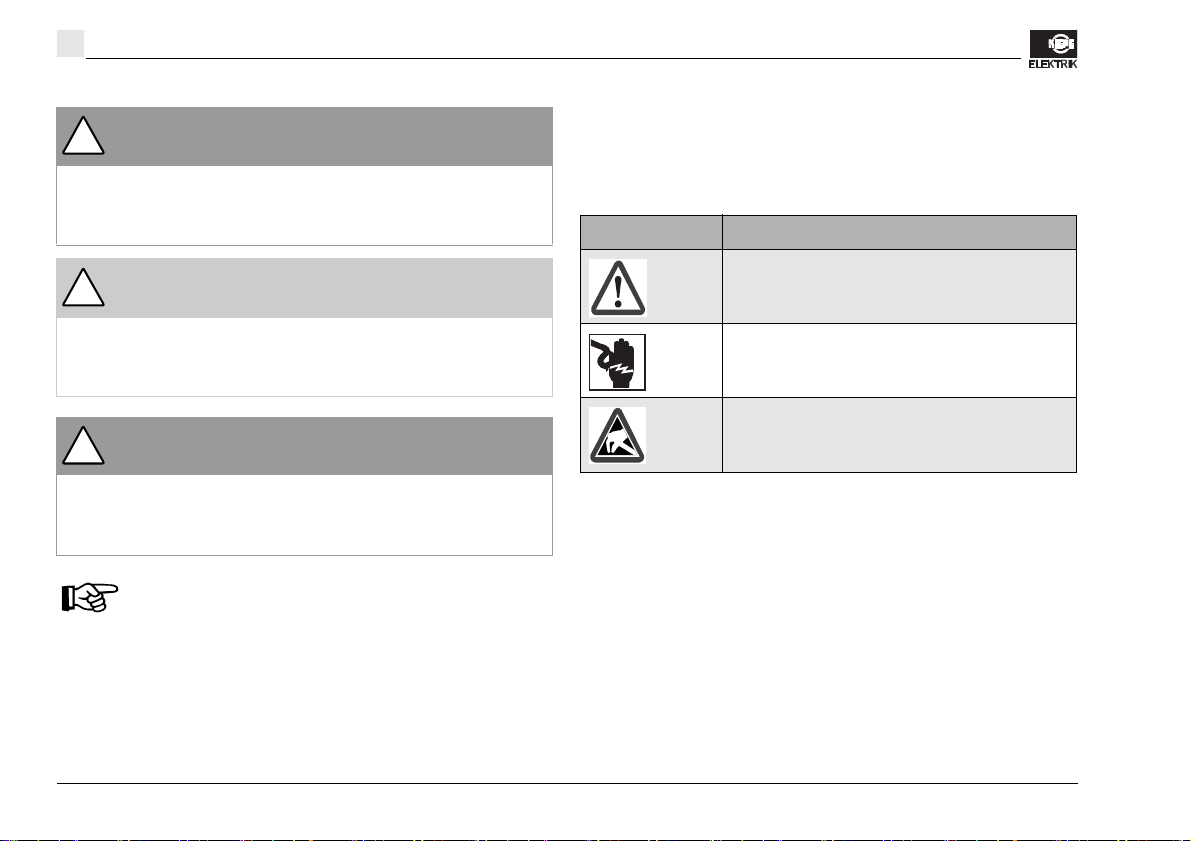

1.2 Design of warnings

Risks are classified in accordance with ISO 3864-2 and

ANSI Z535.6 using the keywords

•“Danger,” “Warning,” and “Caution” in the case of

bodily injury,

•“Beware” in the case of property damage, and

•“Note” to convey general information.

In this documentation, the Risks and Notes are classified

and presented as follows:

Danger!

indicates the immediate threat of danger. Not avoiding

this danger will result in death or extremely serious in-

jury (crippling).