7

EQUIPMENTSAFETYGUIDELINES

• Safetyoftheoperatorandbystandardsisoneofthemain concernsin designingand

developing aseeder.However,everyyear accidentsoccur whichcouldhavebeen

avoided byafewsecondsofthoughtandamorecarefulapproachtohandling

equipment.You,theoperator,canavoid manyaccidentsbyobserving thefollowing

precautions and insistthoseworkingwithyou, orforyou, followthem.

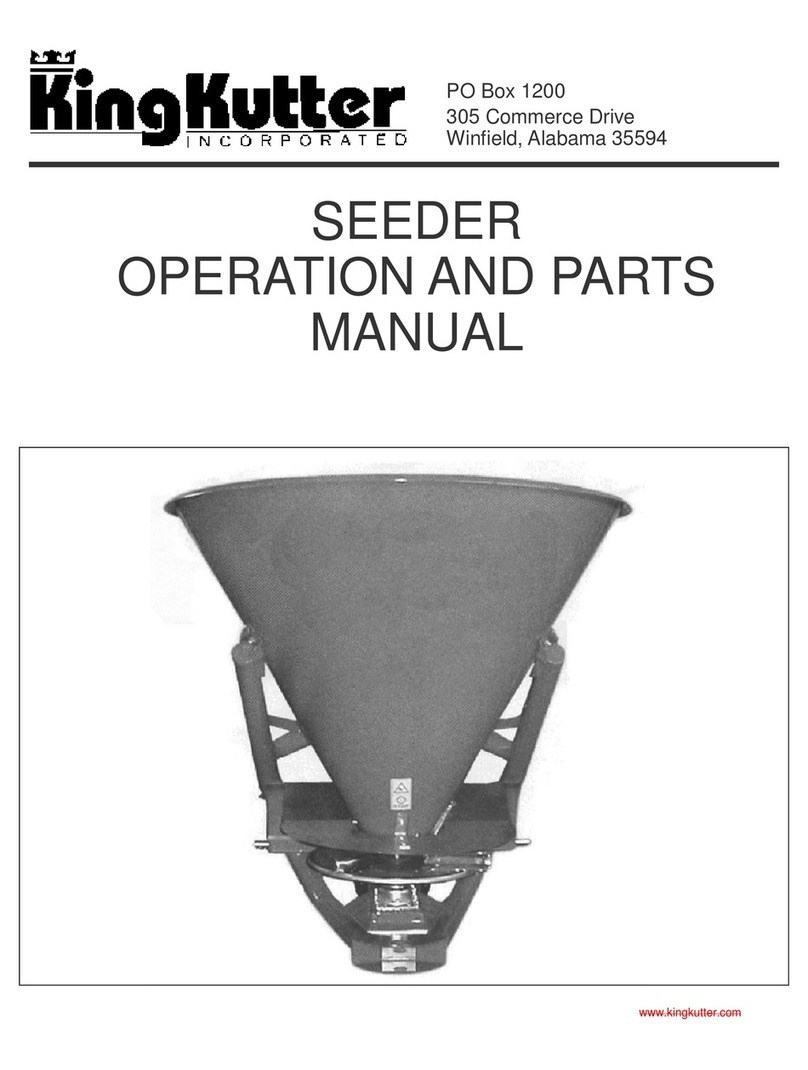

• Inordertoprovide abetterview,certainphotographsorillustrationsinthismanual may

showan assemblywithasafetyshieldremoved.However,equipmentshouldnever be

operatedin thiscondition.Keep allshieldsin place.Ifshield removalbecomes

necessaryfor repairs,replacethe shieldpriortouse.

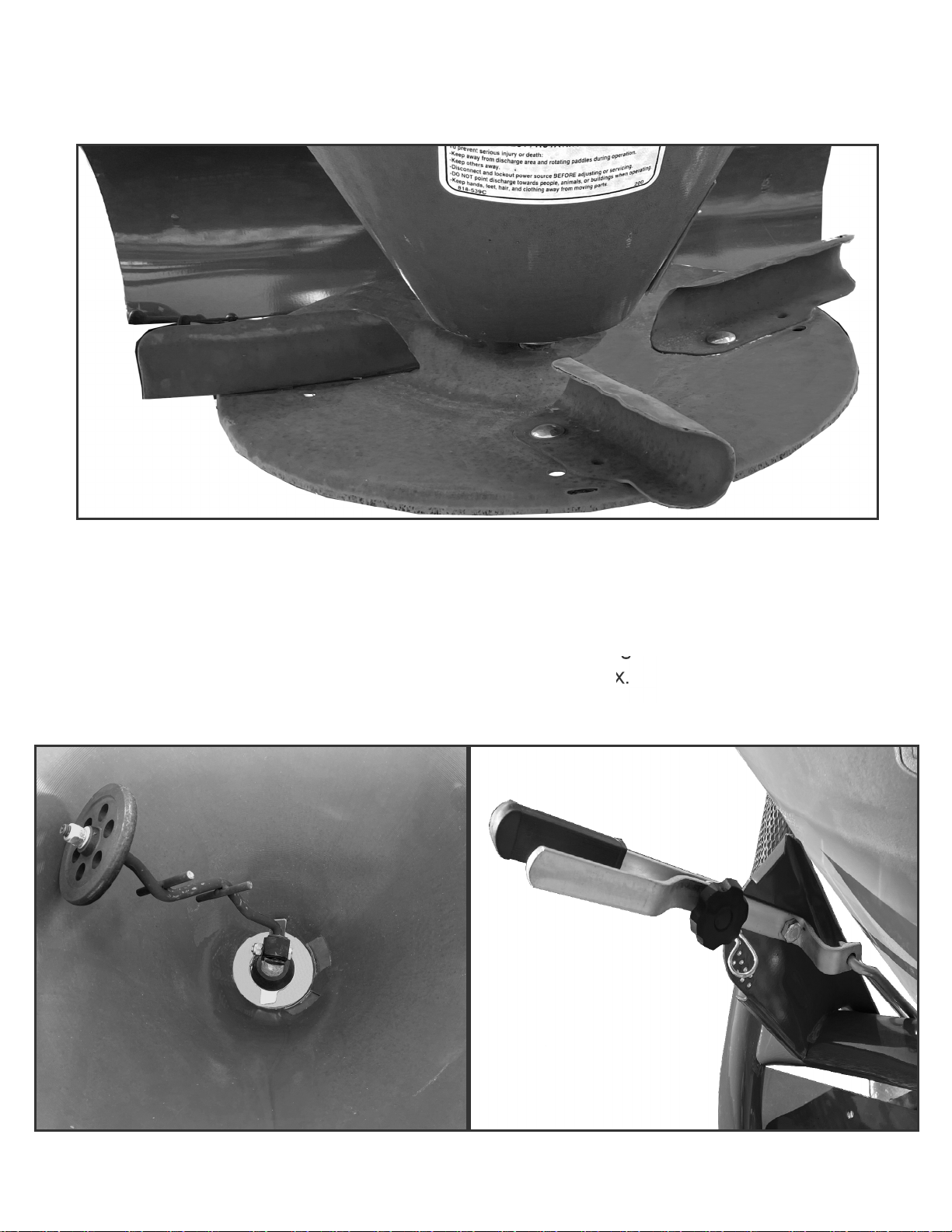

• Replaceanysafetysignthatisnotreadable orismissing.Locationofsuchsafetysigns

is indicatedinthis manual.

• Never usealcoholicbeveragesordrugsthatcanhinderalertnessorcoordinationwhile

operatingthisequipment. Consultyour doctor aboutoperating thismachine while taking

prescription medications.

• Underno circumstances shouldchildrenundertheageof18beallowedtowork

withthisequipment.Donotallowpersonstooperateor assemblethisunituntil

theyhavereadthismanualand havedevelopedathorough understanding ofthe

safetyprecautionsand ofhowitworks.Reviewthesafetyinstructionswithall

usersannually.

• Thisequipmentisdangeroustochildren andpersonsunfamiliar withitsoperation.The

operatorshouldbe aresponsible,properlytrainedandphysicallyable person familiar

withfarmmachineryand trainedinthisequipment’soperations. If the elderlyare

assistingwithfarmwork,theirphysical limitationsneed toberecognizedand

accommodated.

• Useatractorequipped withaRoll OverProtectiveSystemand seatbelts.(ROPS)

• Never exceed thelimitsofapieceofmachinery.Ifitsabilitytodoajob,ortodo so

safely, is inquestion- DON’TTRYIT.

• Donotmodifythe equipmentinanyway.Unauthorizedmodificationcouldresultin

seriousinjuryor deathand mayimpairthefunctionandlifeof the equipment.

• Inaddition tothe design andtheconfirmation ofthisimplement, including safetysigns

and safetyequipment,hazardcontroland accidentprevention aredependent upon the

awareness,concern,prudence,andpropertrainingofpersonnel involved inthe

operation,transport,maintenance,andstorageofthemachine.Referalsotosafety

messagesand operation instruction ineachoftheappropriatesectionsofthe tractor

and seedermanuals.Paycloseattention tothe safetysignsaffixed tothetractor and

the seeder.