4

Models FP2085/FP2785 are Decorative Gas Log Set for

outdoor use only. This appliance MUST NOT be used

for cooking.

WARNING: This appliance shall be used ONLY

outdoors in a well-ventilated space and shall NOT be

used inside a building, garage, or any other enclosed

area.

WARNING: This log set must NOT be installed in an

unvented appliance.

WARNING: THIS UNIT IS NOT FOR USE WITH

SOLID FUEL.

The installation must conform with Local codes ore in

the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 or CAN/CGA-B149.1, National Gas

Installation Code or CAN/CGA-B149.2, Propane

installation Code.

The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in

excess of 1/2 psig (3.5kPa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5kPa).

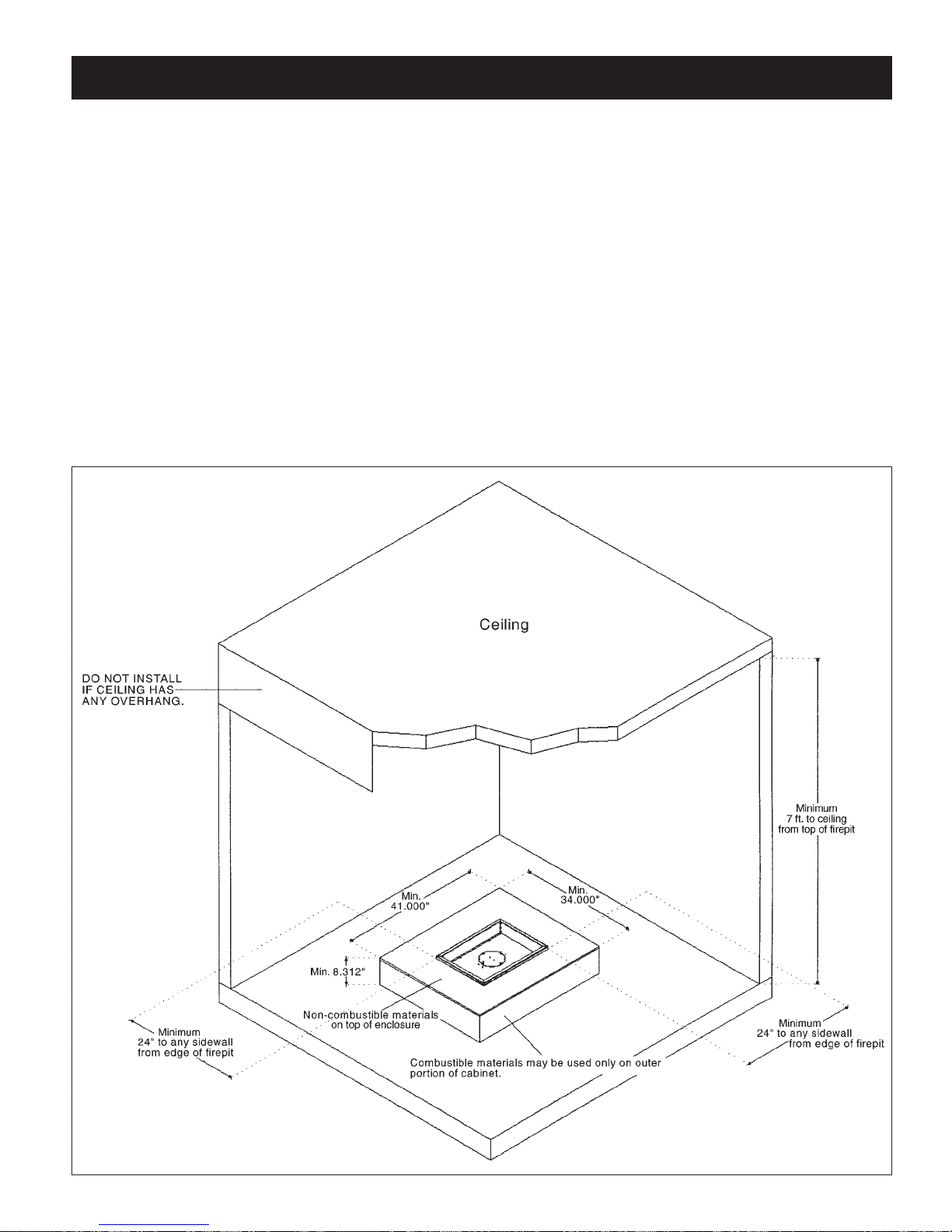

The following clearances to combustible construction

must be maintained: Bottom - 0 inches Sides (all

around)-24 inches (610 mm), and Top-7 feet (2.12 m).

Always keep the appliance area clear and free from

combustible materials, gasoline, and other flammable

vapors and liquids.

Do not locate appliance where it can get excessively wet.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the unit and to replace any part of the control

system and any gas control which has been underwater.

• Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised

when they are in the area of the appliance.

• Clothing or other flammable materials should not

be hung from the appliance, or placed on or near

the appliance.

• Any guard or other protective device removed for

servicing the appliance must be replaced prior to

operating the appliance.

• Installation and repair should be done by a

qualified service person. The appliance should be

inspected before use and at least annually by a

qualified service person. More frequent cleaning

may be required as necessary. It is imperative the

control compartment, burners and circulating air

passageways of the appliance be kept clean.

• Inspect the fuel supply connection (including the

hose for LP models) before each use of the

appliance.

• If it is evident there is excessive abrasion or wear,

or the hose is cut, it must be replaced prior to the

appliance being put into operation.

• The pressure regulator and hose assembly supplied

with LP models must be used. Replacement

pressure regulators and hose assemblies must be

those specified in this manual.

• The LP gas supply cylinder used with LP models

must be constructed and marked in accordance

with the specifications for LP-gas cylinders of the

U.S. Department of Transportation (DOT).

• Cylinders must be stored outdoors in a well-

ventilated area out of the reach of children.

Disconnected cylinders must have threaded valve

plugs tightly installed and must not be stored in a

building, garage or any other enclosed area.

• Storage of this appliance indoors is permissible

only if it has been disconnected from its fuel supply

(natural gas line or LP gas cylinder).

• The LP gas cylinder supply system must be

arranged for vapor withdraws

• The LP -gas cylinder used must include a collar to

protect the cylinder valve.

• When an LP model is not in use, the LP-gas must

be turned off at the supply cylinder.

1.0 INTRODUCTION

For the state of Massachusetts a T-handle gas shut-off valve

must be used on a gas appliance. This T-handle gas shut-off

valve must be listed and approved by the state of Massachusetts.

This is in reference to the state of Massachusetts state code

CMR238.