Your safety and the safety of

others are very important,

We have provided many important

safety messages in this manual

and on your appliance. Always

read and obey all safety

messages.

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will follow the

safety alert symbol and either the

word "DANGER" or "WARNING".

These words mean:

You can be killed or seriously

injured if you don't immediately

foltow instructions.

You can be killed or seriously

injured if you don't foltow

instructions.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructionsare not followed.

mmportant: Observe aH governing

codes and ordinances,

Proper installation is your

responsibility. Make sure you have

everything necessary for correct

installation. It is the responsibility

of the installer to comply with the

installation clearances specified on

the model/serial rating plate.The

model/serial rating plate is located

on the front of the downdraft vent

above the wiring box cover.

Mobile home installation

The installation of this range hood

must conform to the Manufactured

Home Construction Safety

Standards, Title 24 CFR, Part 328

(formerly the Federal Standard for

Mobile Home Construction and

Safety, Title 24, HUD, Part 289) or

when such standard is not

applicable, the Standard for

Manufactured Home Installation

1982 (Manufactured Home Sites,

Communities and Setups) ANSI

A225.1/NFPA 591A*, or latest

edition, or with local codes.

Check location where downdraft

vent will be installed.The location

should be away from strong draft

areas, such as windows, doors

and strong heating vents or fans.

Before making countertop cutout,

check that downdraft vent and

cooktop location will clear cabinet

walls, backsplash, and rear wall

studs inside cabinet.

ALL OPENINGS IN THE WALL OR

FLOOR WHERE RETRACTABLE

DOWNDRAFT VENT iS TO BE

INSTALLED MUST BE SEALED.

Electrical ground is required. See

"Electrical requirements;' page 3.

When installing downdraft vent,

the cabinet drawer will need to be

removed and the drawer front

installed permanently to cabinet.

Note: Downdraft vent is installed

directly behind the cooktop. Install

downdraft vent first.

Cabinet construction: Downdraft

vent is designed for use in a

cabinet with a depth of 24"

(61 cm). Some installations

require a countertop deeper than

25" (63.5 cmL See chart on page 5.

The maximum depth of the

overhead cabinet is 13" (33 cm).

Overhead cabinets installed at

either side of the downdraft vent

must be 18" (45.7 cm) above the

cooking surface.

See cooktop Installation

instructions before making any

cutouts and for the minimum

distance between the front edge

of the countertop and front edge

of cooktop.The minimum

horizontal distance between the

overhead cabinets is the same as

the width of the installed

downdraft vent.

When installing a 36" (91.4 cm)

retractable downdraft vent with

"Create-A-Cooktop" modules, the

optional support must be installed

on the front of the downdraft vent.

See installation steps for details.

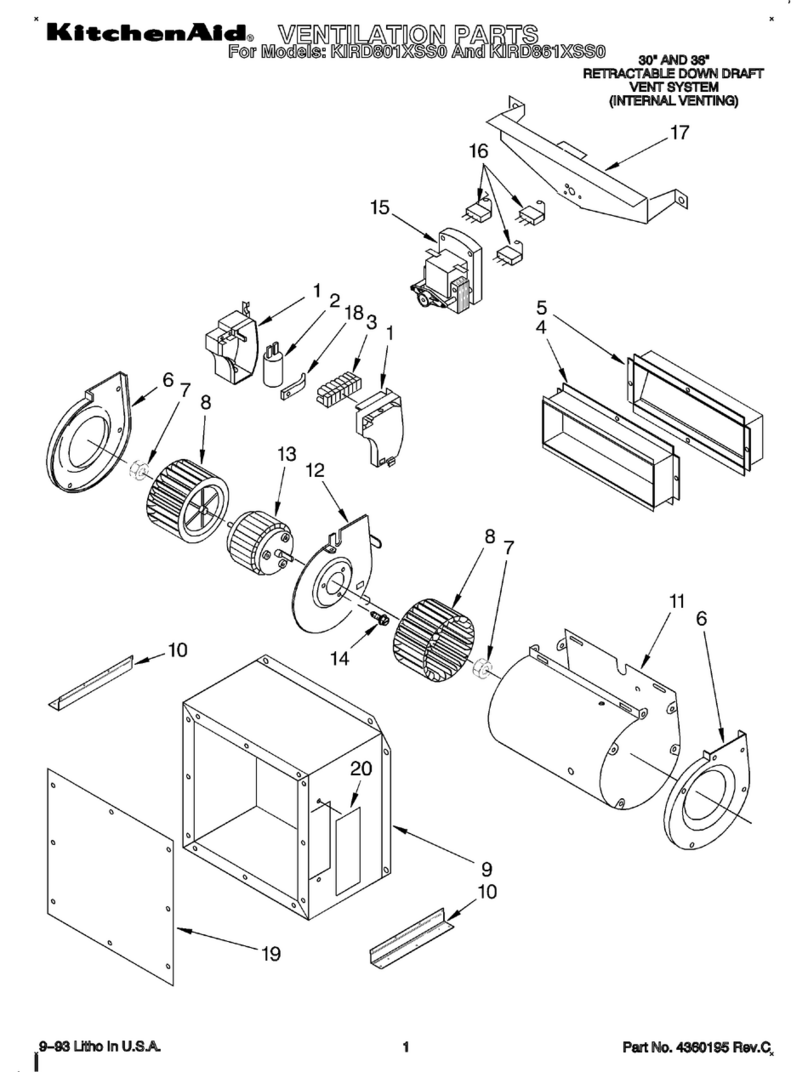

Parts supplied

for installation:

•t top trim

2 end cape

•2 lower support legs

2 overcounter support brackets

2 undemounter mounting brackets

•1 bag of fasteners

t meta_ cover

• 1 backdraft damper

•literature package

• optional support and two screws

(36" (91.4 era) models only

Parts needed

for installation:

• 2 U.L.= or C.S.A.4isted 1/2" (12.7 ram)

conduit connectors (3 are required if

the exterior-mounted vent motor is

used.}

• 1 wall cap for interior-mounted motor

• vent system

• power supply cable

• wiring cable for optiona_ remote b_ower

kit.

Tools needed for

installation:

•safety glasses

•g_oves

•jig or keyhole saw

• drill with 118" drill bit

• pencil

• measuring tape

• flat=b_ade screwdriver

• Phillips screwdriver

•318" (9.5 ram} nut driver or ratchet

•leve_

•pliers

•metal snips

• wire stripper or utility knife

caulking gun and weatherproof caumk

• duct tape