Female XLR

Male XLR

Pin 1 - Screen/Ground

Pin 2 - Hot Signal

Pin 3 - Cold Signal

Pin 1 - Screen/Ground

Pin 2 - Hot Signal

Pin 3 - Cold Signal

Note: XLR Sockets are viewed from the

front face.

Phoenix Type Connector

Pin 1 - Channel IN Screen/Ground

Pin2 - Channel IN Hot Signal

Pin 3 - Channel IN Cold Signal

Pin 4 - Channel OUT Screen/Ground

Pin 5 - Channel OUT Hot Signal

Pin 6 - Channel OUT Cold Signal

Note: Pin assignments as viewed from the

socket. Phoenix connector is wired in parallel with

the corresponding XLR.

The following special limitations must be observed in order to maintain safety and electromagnetic compatibility

performance.

Power Connection

The DN370 Graphic Equaliser should only be operated with the

power supply connected to ground via the ground in the mains

connector.

Audio Connections

The DN370 should only be operated with high quality twisted-

pair audio cables. XLR connector shells should be of metal

construction so that they provide a screen when connected to

the console and should have pin one (1) connected to the cable

screen.

Electric Fields

If the DN370 is operated in an electromagnetic field that is

amplitude modulated by an audio frequency signal, the signal

to noise ratio may be degraded. Degradation of up to 60dB

may be experienced under extreme conditions (3V/m, 90%

modulation).

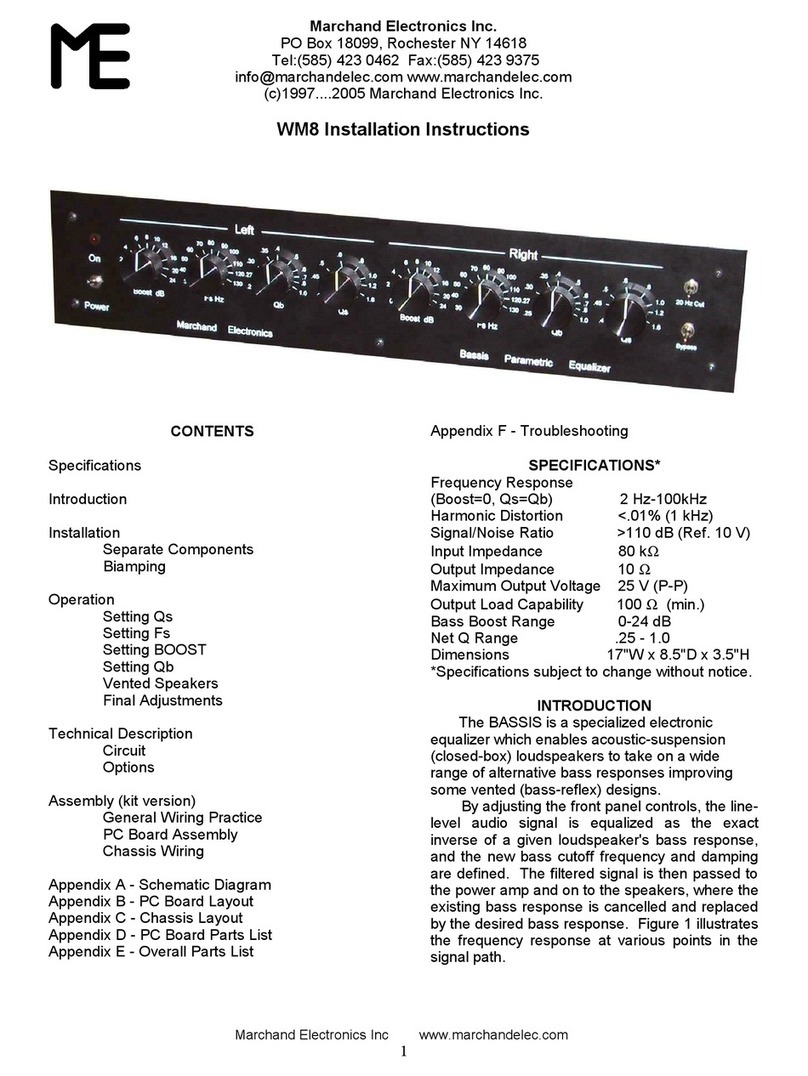

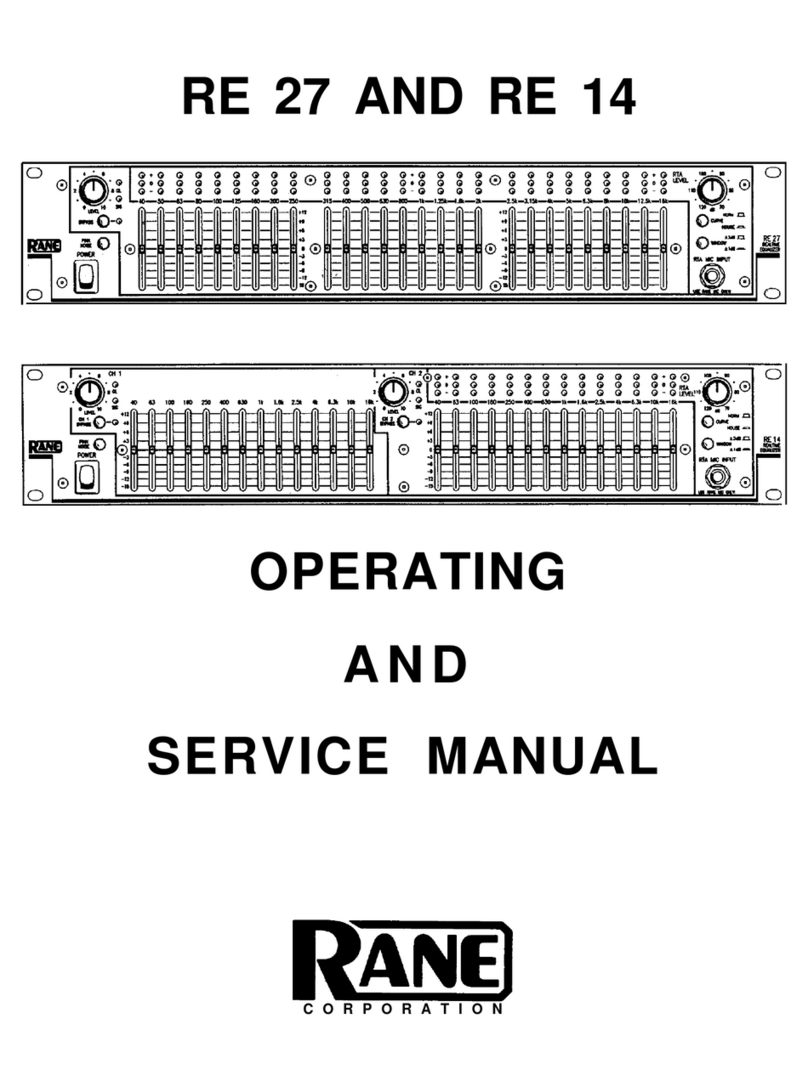

INSTALLATION

Position

Power

The DN370 should be mounted in a nineteen inch (19”) rack of suitable construction for it’s intended purpose. Four (4) rack

mount holes are provided through the front panel to support fully, the weight of the unit in the rack. Position of the unit will

depend upon how it is to be used however:-

- Avoid placing the unit such that the faders may be accidentally knocked or snapped off

- Avoid placing the unit such that the front mounted power switch may be accidentally knocked

Also try to avoid placing the unit directly near or on any power distribution units or power amplifiers.

The internal power supply is a switch mode type which automatically senses the incoming mains voltage and will work where the

nominal voltage is in the range 100-240 VAC. A single fused IEC mains inlet is provided on the rear panel and the correct lead for

connection in the area to which the unit was shipped is provided in the box.

Connections

After Unpacking

To ensure the correct and reliable operation or your DN370 Graphic Equaliser, only high quality balanced screened twisted pair

audio cable should be used.

After unpacking your DN370, please retain the original packing in the event that you should need to transport or ship the unit.

Please inspect the unit carefully for any signs of damage that may have occurred in transit and notify the courier immediately if

you feel that any damage has occurred.

1

2

3

12

3

123456

ATTENTION

DN Operators Manual -370 Page 2