4

IMPORTANT PRECAUTIONS AND RECOMMENDATIONS

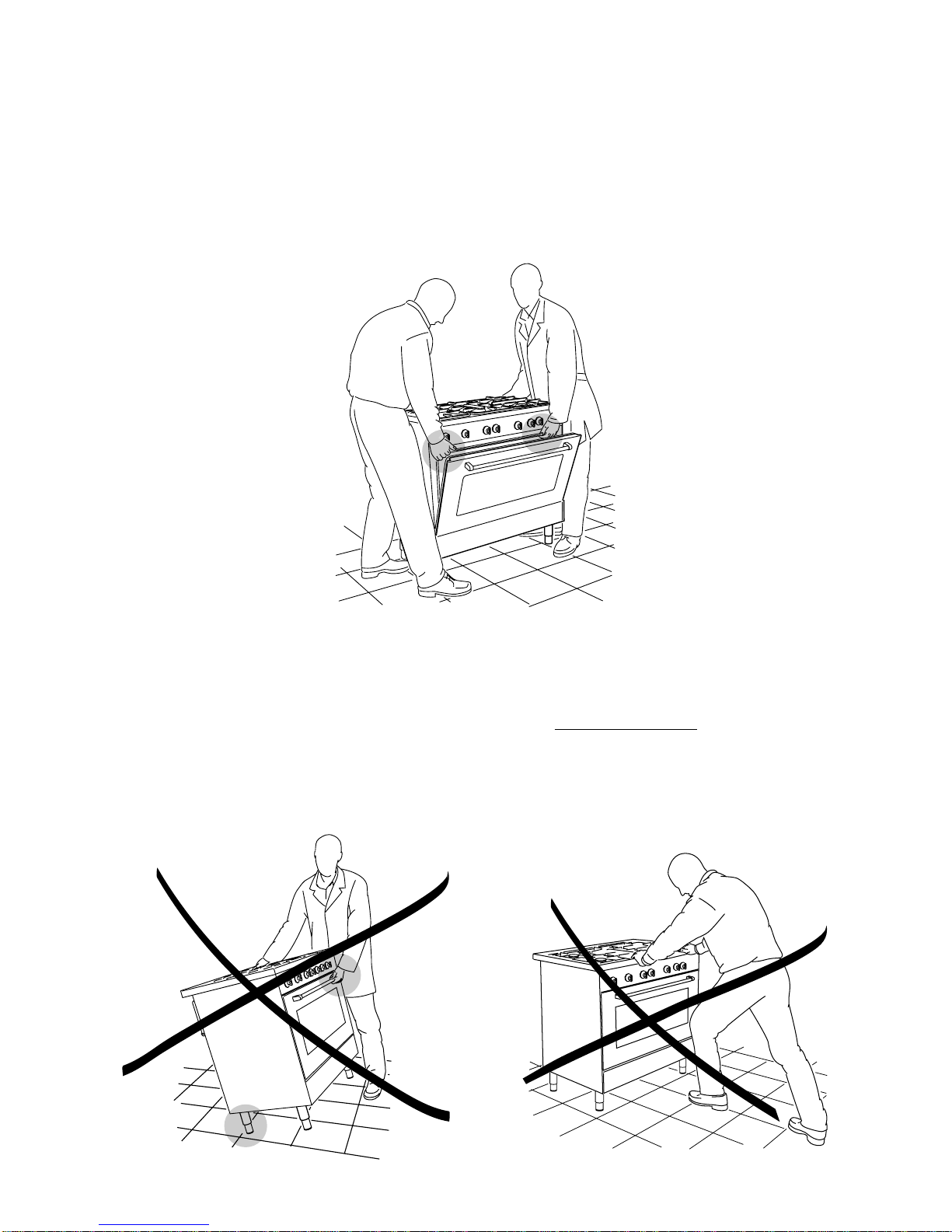

After having unpacked the appliance, check to ensure that it is not damaged.

In case of doubt, do not use it and consult your supplier or a professionally qualified techni-

cian.

Packing elements (i.e. plastic bags, polystyrene foam, nails, packing straps, etc.) should not

be left around within easy reach of children, as these may cause serious injuries.

■Do not attempt to modify the technical characteristics of the appliance as this

may become dangerous to use.

■Do not carry out cleaning or maintenance operations on the appliance without

having previously disconnected it from the electric power supply.

■After use, ensure that the knobs are in off position.

■Do not allow children or other incapable people to use the appliance without

supervision.

■During and after use of the cooker, certain parts will become very hot. Do not

touch hot parts.

■Keep children away from the cooker when it is in use.

■Some appliances are supplied with a protective film on steel and aluminium parts.

This film must be removed before using the appliance.

■Fire risk! Do not store flammable material in the oven, and in the storage

compartment.

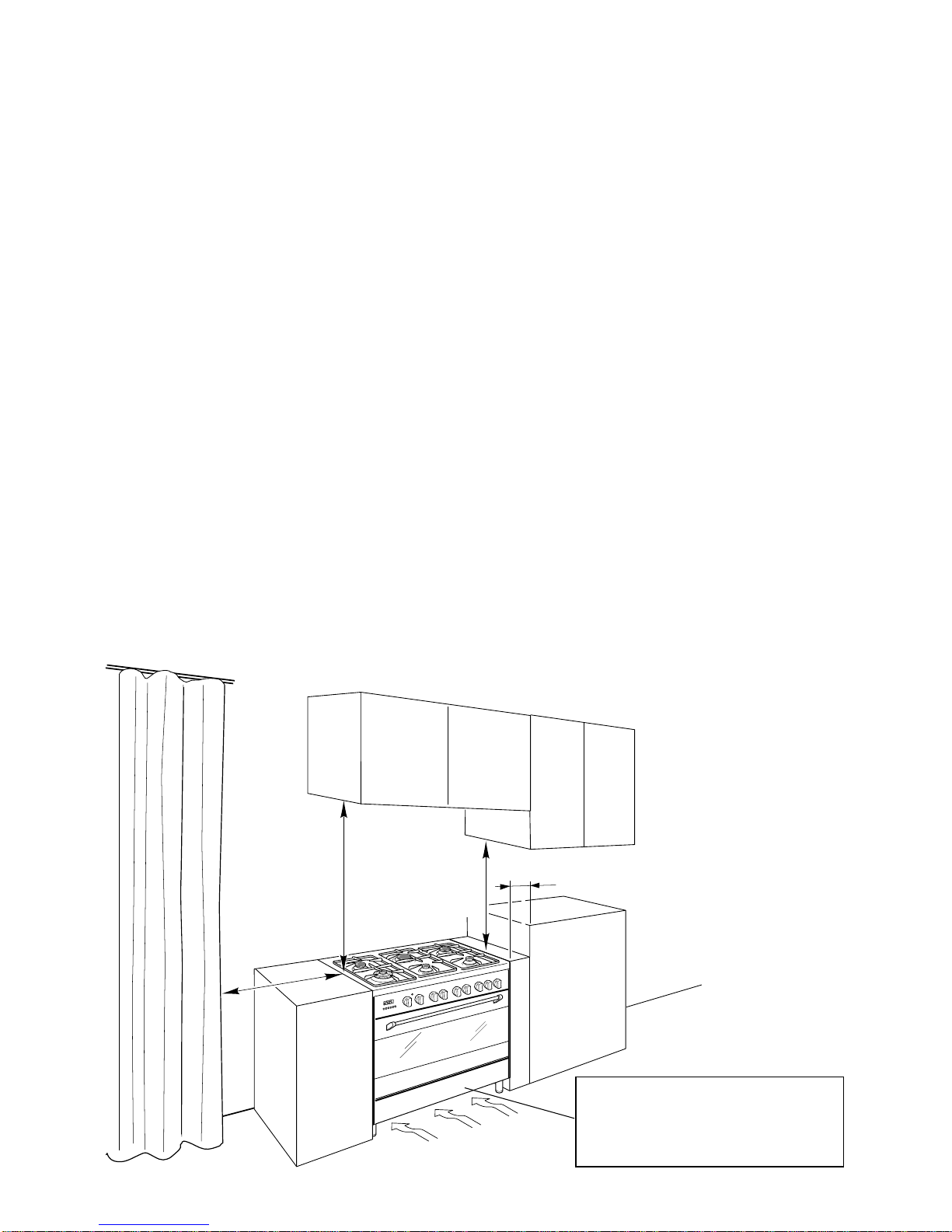

■Make sure that electrical cables connecting other appliances in the proximity of

the cooker cannot come into contact with the hob or become entrapped in the

oven door.

■Do not line the oven walls with aluminium foil. Do not place baking trays or the

drip tray on the base of the oven chamber.

■The manufacturer declines all liability for injury to persons or damage to property

caused by incorrect or improper use of the appliance.

■To avoid any possible hazard, the appliance must be installed by qualified

personnel only. Any repairs by unqualified persons may result in electric shock or

short circuit. In order to avoid possible injuries to your body or to the appliance,

do not attempt any repairs by yourself. Such work should be carried out by

qualified service personnel only.

■Danger of burns! The oven and cooking accessories may become very hot

during operation. Make sure children are kept out of reach and warn them

accordingly. To avoid burns use kitchen clothes and gloves when handling hot

parts or utensils.

■Never clean the oven with a high-pressure steam cleaning device, as it may

provoke a short circuit.

■This appliance is intended for use in your household. Never use the appliance for

any other purpose!

■IMPORTANT NOTE: This appliance shall not be used as a space

heater, especially if installed in marine craft or caravans.