Installation instruction for radial blowers for areas subject to gas and dust explosion hazards

02/2016 KARL KLEIN Ventilatorenbau GmbH

2 Designated use

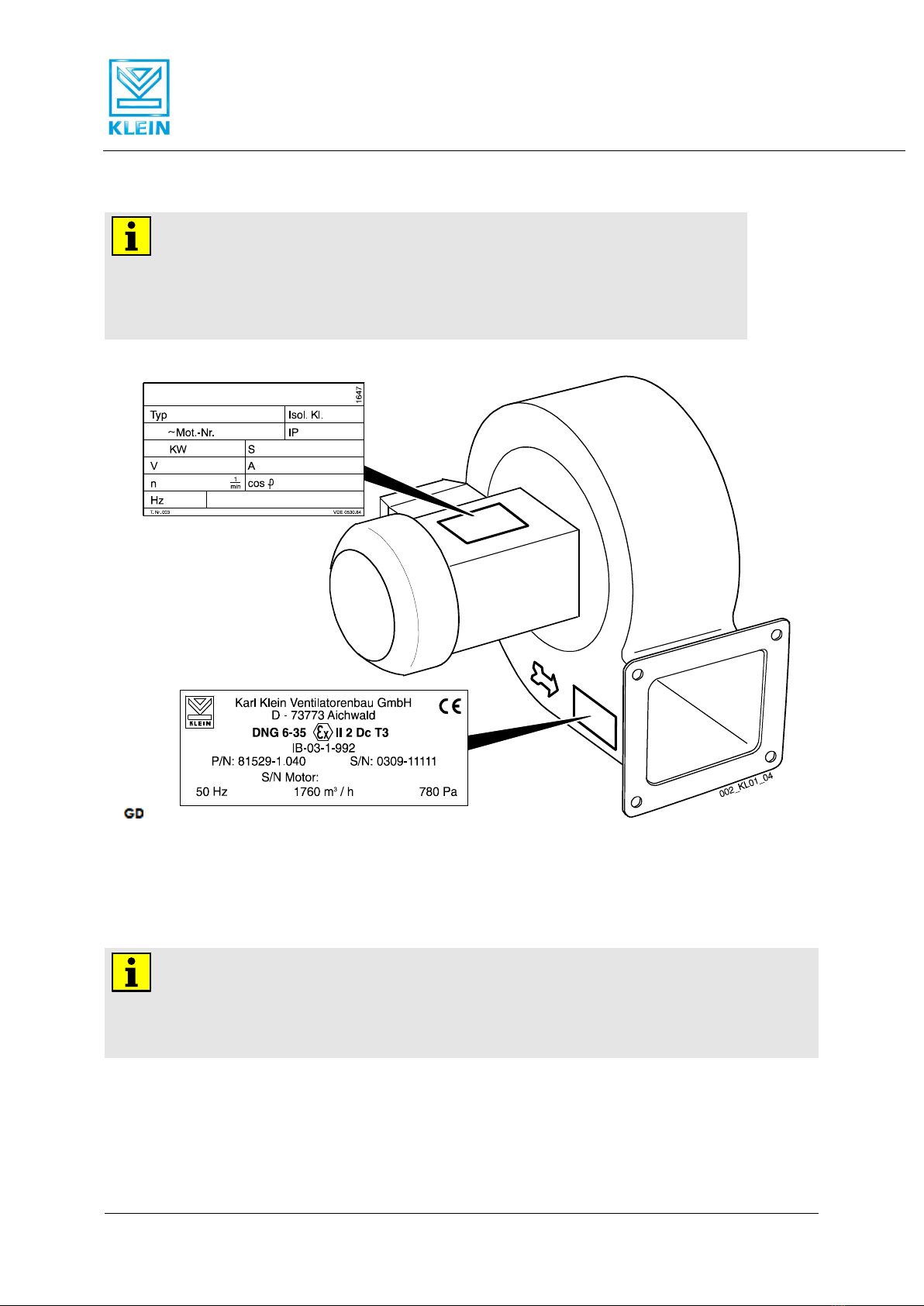

Instruction!

For instance, the blower may be labeled as II 2 GD c IIB T4

Equipment class II; Category 2; D = Dust; G = Gas; c = design safety

IIB = explosion subgroup according CENELEC / IEC / NEC 505

T3 = up to 200 °C surface temperature

T4 = up to 135 °C surface temperature

The blower can be used in atmospheres subject to dust and gas-explosion hazards for

zones 1 and 2, 21 and 22.

In reference to EN 1127-1, this means for Zone 1 that the blower is intended for use in those

areas where an atmosphere capable of producing an explosion, in the form a mixture of

combustible gas, vapor or mist with air, may occasionally form under normal operating

conditions.

In reference to EN 1127-1, this means for Zone 2 that under normal operating conditions, an

atmosphere capable of producing an explosion, in the form a mixture of combustible gas,

vapor or mist with air, normally does not form or only forms for brief periods.

In reference to EN 1127-1, this means for Zone 21 that the blower is intended for use in

those areas where an atmosphere capable of producing an explosion, in the form of a

combustible dust-cloud mixed with air may occasionally form under normal operating

conditions.

In reference to EN 1127-1, this means for Zone 22 that under normal operating conditions,

an atmosphere capable of producing an explosion, in the form of a combustible dust-cloud

mixed with air, normally does not form or only forms for brief periods.

The designated use encompasses observing and complying with the specifications and

instructions in this Installation instruction.

2.1 Limitations to the use and special considerations for

designated uses

The designated operation also includes:

The conveyed medium may not contain solid or liquid contaminants. Use a filter as

needed (see KLEIN list of accessories).

When conveying aggressive media, the blower corrosion protection mechanisms must

first be adapted to the material characteristics. (Consult the manufacturer).

If the blower is to be used in an open blowing configuration, or if it is likely that a hazard

exists for the downstream machine or installation if the blower wheel breaks, a

protective screen must be mounted to the blower exhaust opening.

The blower may only be operated in an installed condition, i.e. mounted to or into

systems and machines.

Ventilated air flow at fan inlet with higher or lower values than the specified limits of 0.8

to 1.1 bar for absolute pressure and –20°C to +60°C for temperature are not permitted,

max. allowed oxygen content is 21 volume percent.

Ambient atmospheres with higher or lower values than the specified limits of 0.8 to 1.1

bar for absolute pressure and –20°C to +40°C for temperature are not permitted, max.

allowed oxygen content is 21 volume percent.

The blower may only be operated with an installed intake protective screen.