Fans:

The paint station ought to be connected to the single fan working with one filtering paint station

or cooperating with a ventilation system with one central extraction fan. As the extracted air is

expelled outside the building (no recirculation), it is recommended applying a roof fan.

5. Structure and Function

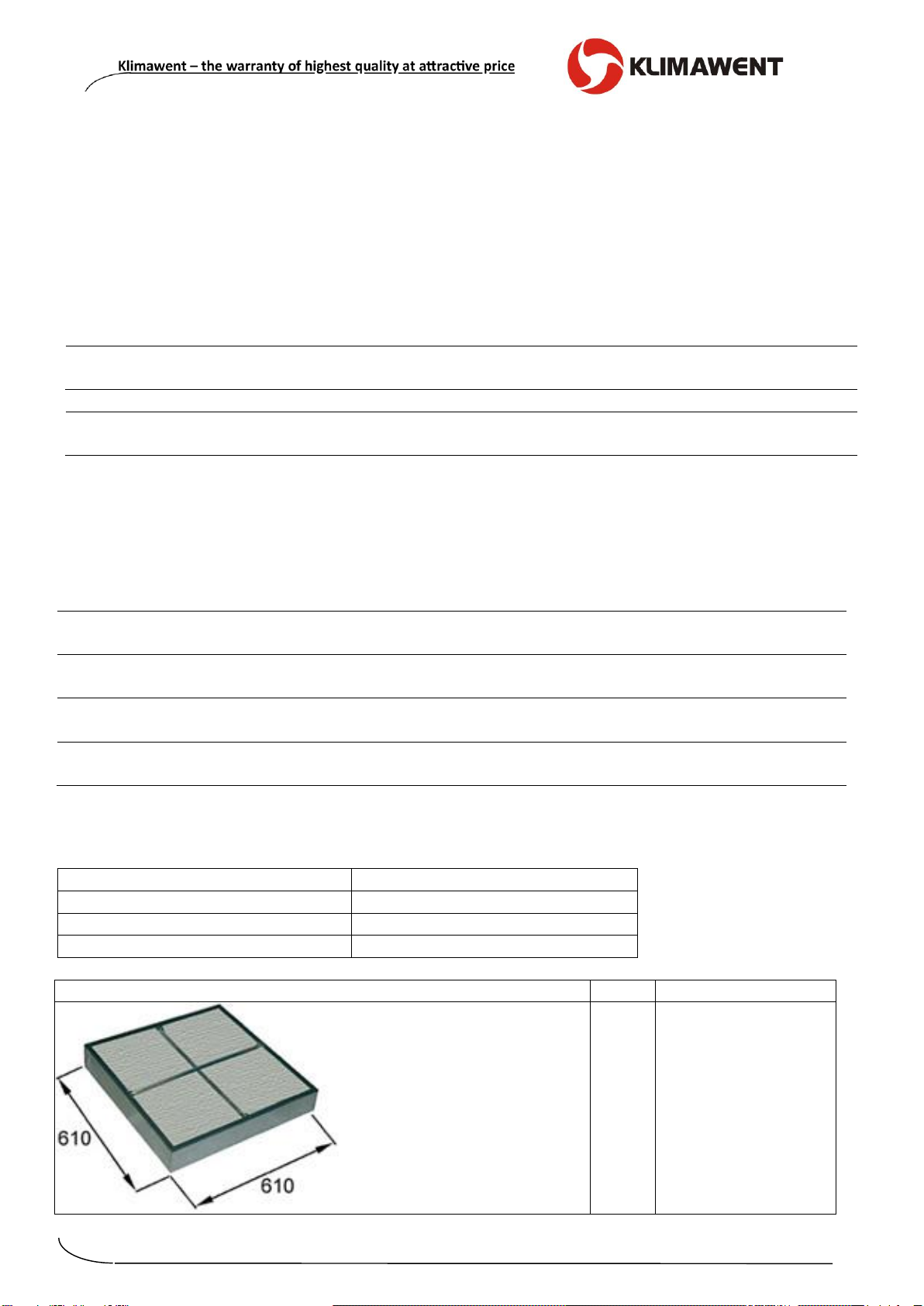

FPS-1 is a one-segment ventilation wall, whereas FPS-2 consists of two segments. In each se-

gment is located a replaceable filter cartridge, providing labyrinthine air flow.

On this filter (of capture efficiency 50%) are depositing paint particles. Behind the labyrinthine

filter are placed 3 spunbond filters (FPS-1) or 6 spunbond filters (FPS-2). Nonwoven filter ope-

rates as the second filtration stage, increasing the filtration efficiency up to 90%.

Each segment of the filtering station is equipped with a connection fitting piece, discharging to

the ventilation ducting.

As standard, the connection piece is installed on the right side wall. The connection piece can

be re-installed to the left side wall or to the upper surface of the segment. All walls are equip-

ped with a two side swinging boards and one top swinging board.

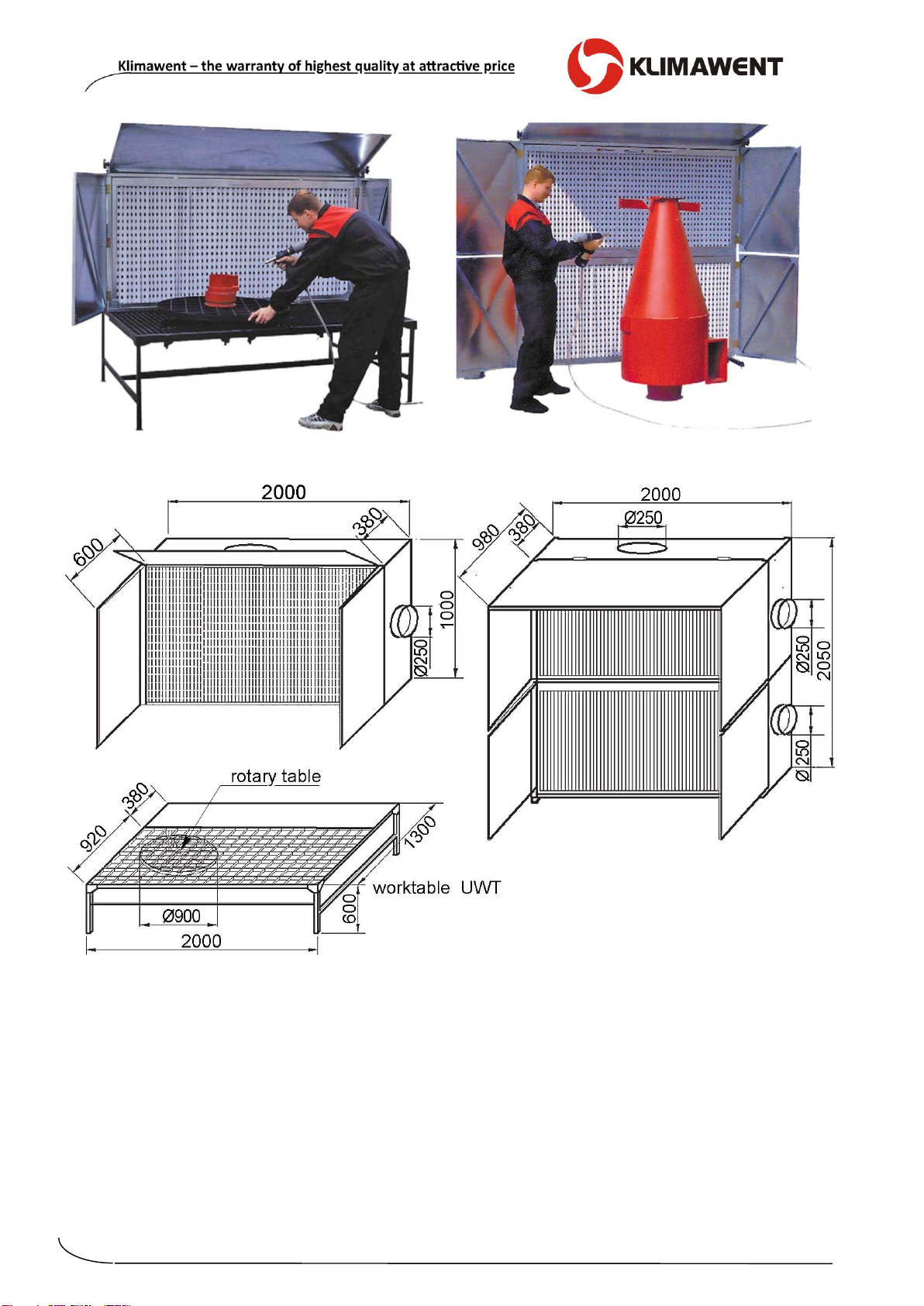

FPS-1 paint station can be installed on a UWT work table, creating a universal ventilation post

with a grate to put the painted elements on it and a rotary table.

The filtration walls should be connected to the extraction fans of flow efficiency 3000 m3/h per

each segment.