4

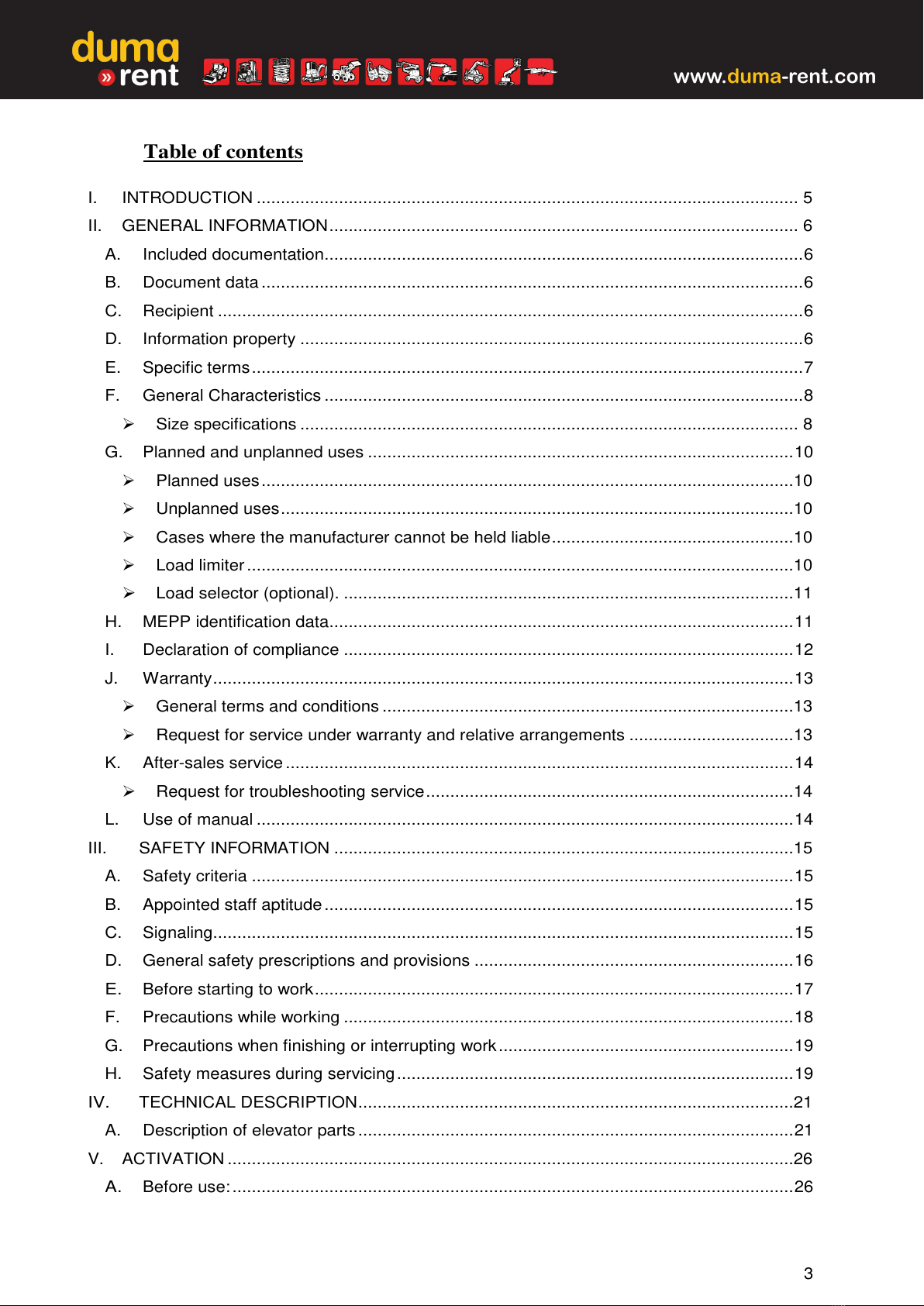

B. Position and description of the main elements...............................................................28

C. Elevator operation .........................................................................................................32

D. Stabilization outriggers ..................................................................................................34

VI. EMERGENCY MANEUVERING AND PROCEDURES...................................................35

A.

Emergency shutdown ....................................................................................................35

B. Emergency pump ..........................................................................................................35

C. Override (optional).........................................................................................................35

D. Hydraulic distributors .....................................................................................................36

E. Actuator control .............................................................................................................37

VII. MAINTENANCE .............................................................................................................41

A. Daily inspection .............................................................................................................42

Weekly inspection .................................................................................................................43

Bimonthly inspection .............................................................................................................43

Six monthly inspection...........................................................................................................43

Compulsory servicing after one year or 500 hours of use (whichever comes first).................44

Hydraulic oils / filters .............................................................................................................45

Greasing................................................................................................................................45

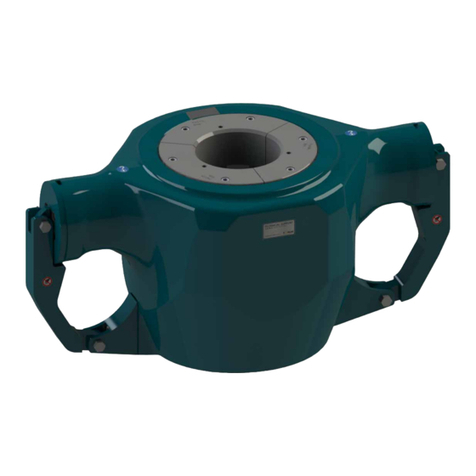

Slew ring.....................................................................................................................45

Shafts .........................................................................................................................45

Warranty cover......................................................................................................................46

Diagnostic .............................................................................................................................46

VIII. ELIMINATION AND DEMOLITION.................................................................................49

A. Operator qualification.....................................................................................................49

Equipment deactivation .........................................................................................................49

Deactivation procedure..........................................................................................................49

Remaining risks after deactivation.........................................................................................49

IX. HYDRAULIC AND ELECTRIC DIAGRAMS....................................................................50

A. Hydraulic drawings ........................................................................................................50

B. Circuit drawings.............................................................................................................51

A.

Writing instructions ........................................................................................................52

B. Delivery of platforms owner ...........................................................................................52

C. Successive ownership transfers ....................................................................................53

D. Replacement of parts.....................................................................................................54

E. Safety replacement........................................................................................................57

F. Checking / repairs / maintenance ..................................................................................59

G. Notes.............................................................................................................................62