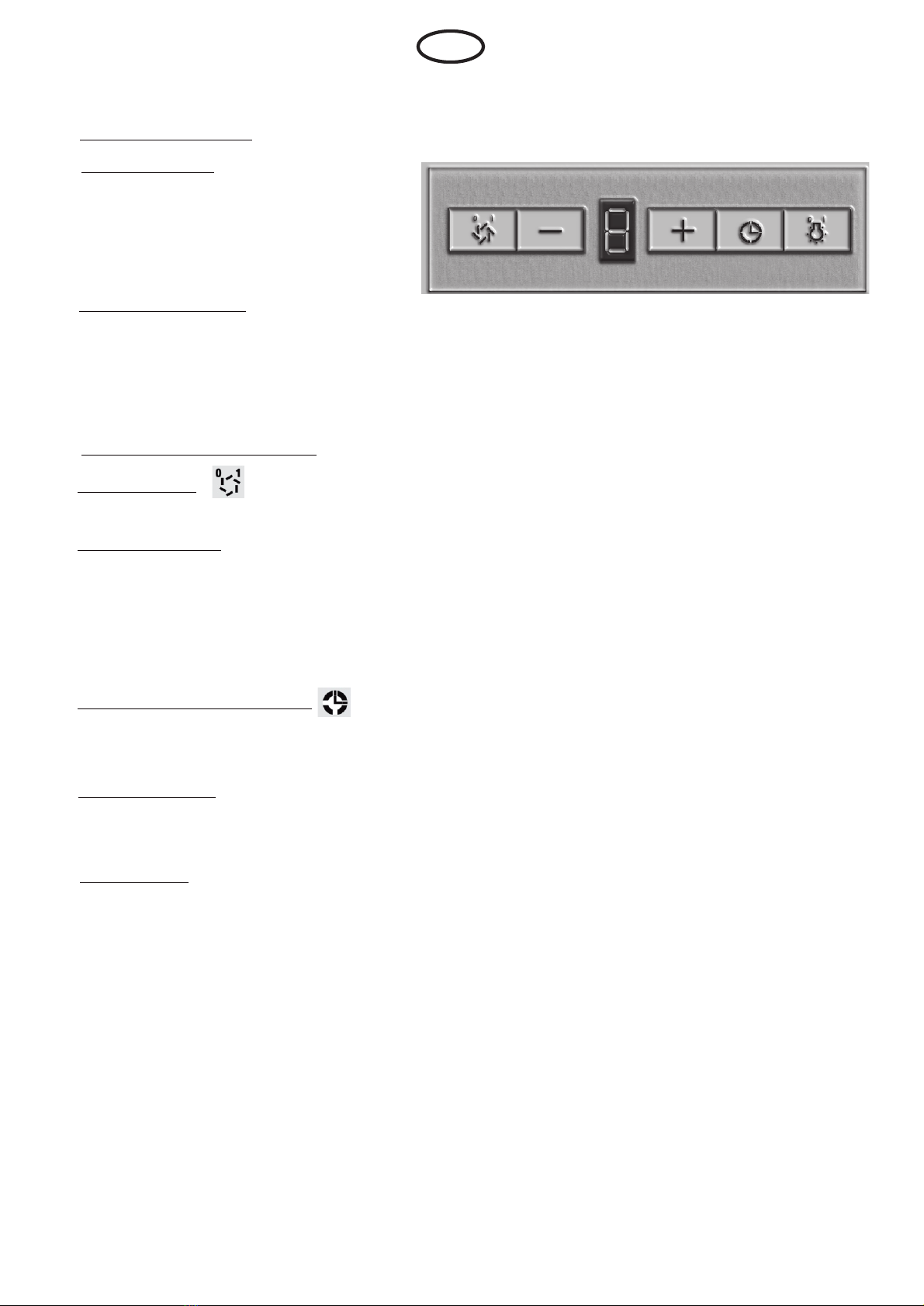

EN

*This product is designed to be used

*Operational power supply is AC 220-

240 Volts 50Hz.

*Your product has the earthed plug

cable.This cable must be connected

to AC power supply which is fully

*All electrical wiring must be done by

a qualified electrician.

*Unauthorized installation can be work

in poor performance and damage to the

product and lead to accidents.

*Make sure the power cable is not

pinched and not crushed to during

installation. The power supply cable

must not pass near the stove.

It may be melting and cause a fire.

*Do not connect the unit to the power

supply unless the assembly of the

*In case of any danger,power off the

product easly accessible to ensure that

your plug.

*Do not touch the illumination lamps of

the device when they are used for

a long time.

*Hoods are made for home use while

cooking. If used for other purposes,

there is a risk of malfunction and

interests outside of warranty.

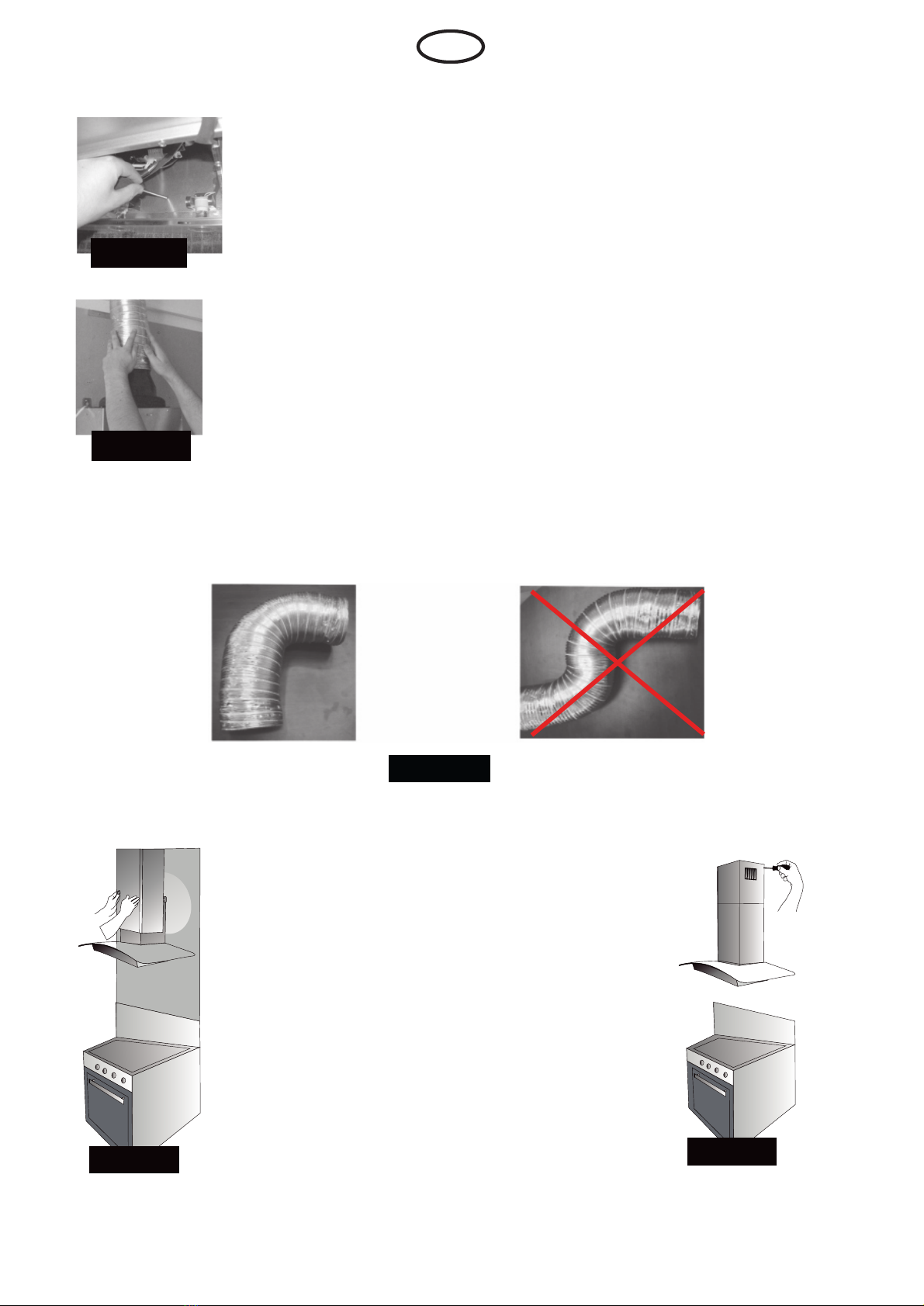

*About the evacuation of the outlet air,

Please follow the rules and guidelines

of the authorities.

WARNINGS AND SAFETY PRECAUTIONS

*Flammable foods should not be cooked

under this device.

*Operate the Hood Fume after placing

the casserole and pan on the cooker.

Otherwise, in some parts of the device

may result deformed due to high

temperature.

*Out of the stove pots,pans and so on.

Turn off the stove before.

*Do not leave hot oil on the stove.

Spontaneously flammable in containers

with hot oil.

*Please be careful. Roast type, etc..

While food oils can ignite and cause fire

damage.

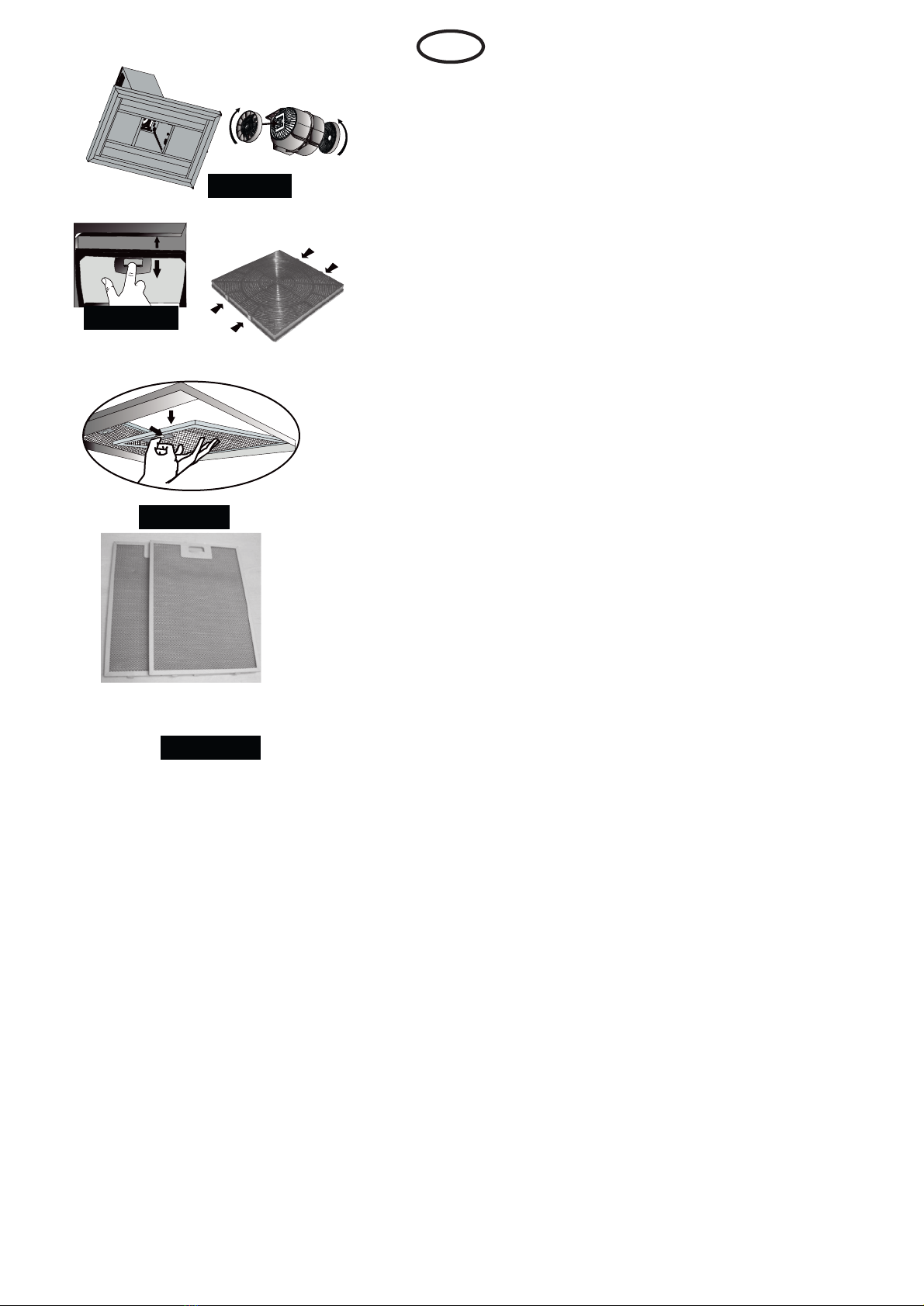

*Ensure the timely replacement or cleaning

of the filters.Accumulated on the filter is

a risk of fire due to the oil.

*Only use the metal filter provided with

the device and do not use other materials

*Do not operate the device without it’s filter.

Do not remove the metal filter of the device

while it is operating.

*In case of flare begin, turn off energy of

hoods and cookers.

*The cleaning of the device should be

implemented with periodic intervals.

*Turn off your device before maintenance

at home

grounded.

device is fully completed.

to replace it.

operations.

2