Ceramat WA153

iii

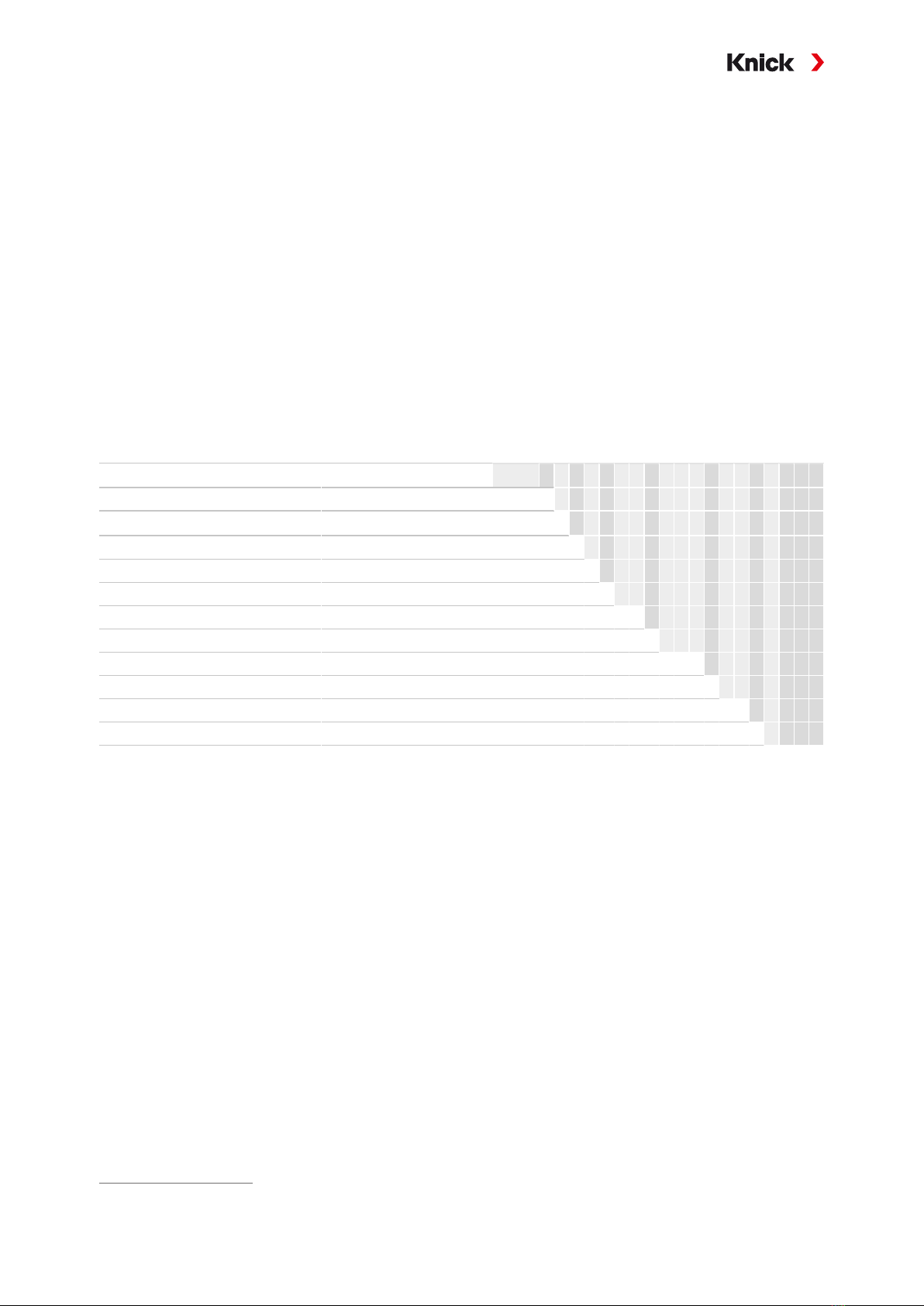

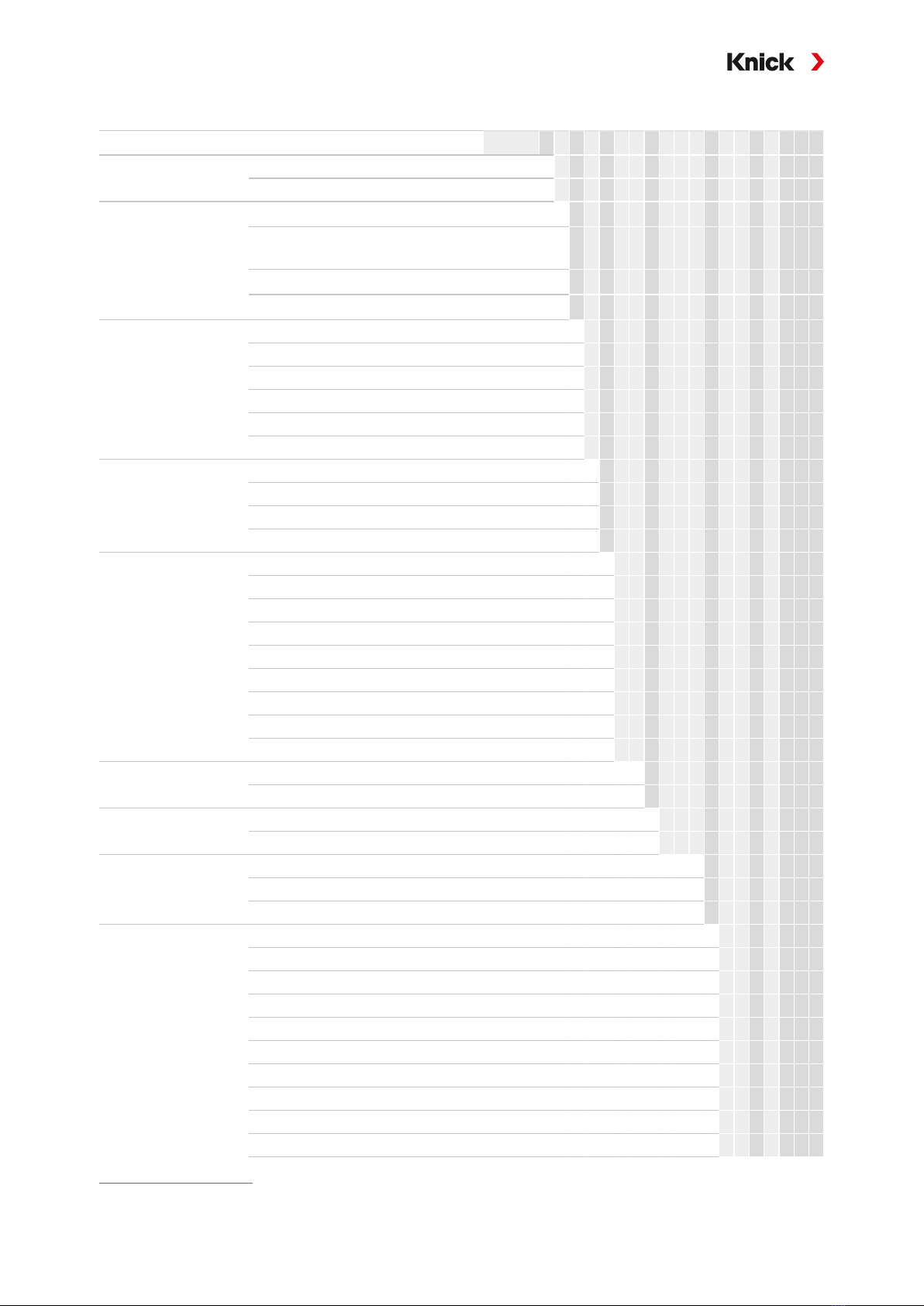

Table of Contents

1 Safety............................................................................................................................................. 5

1.1 Intended Use.......................................................................................................................................................... 5

1.2 Personnel Requirements.................................................................................................................................... 5

1.3 Safeguards .............................................................................................................................................................. 6

1.4 Residual Risks......................................................................................................................................................... 6

1.5 Hazardous Substances........................................................................................................................................ 7

1.6 Operation in Explosive Atmospheres............................................................................................................ 7

1.6.1 Possible Ignition Hazards During Installation and Maintenance........................................... 7

1.6.2 Possible Ignition Hazards During Operation................................................................................. 8

1.7 Safety Training....................................................................................................................................................... 8

1.8 Maintenance and Spare Parts .......................................................................................................................... 8

2 Product.......................................................................................................................................... 9

2.1 Package Contents................................................................................................................................................. 9

2.2 Product Identification......................................................................................................................................... 9

2.2.1 Example of a Version.............................................................................................................................. 9

2.2.2 Product Code............................................................................................................................................ 10

2.3 Nameplates............................................................................................................................................................. 12

2.4 Symbols and Markings ....................................................................................................................................... 14

2.5 Design and Function........................................................................................................................................... 14

2.5.1 Retractable Fitting .................................................................................................................................. 15

2.5.2 Drive Units ................................................................................................................................................. 16

2.5.3 Process Connections.............................................................................................................................. 16

2.6 Changes for Different Conditions................................................................................................................... 17

2.7 SERVICE/PROCESS Limit Positions ................................................................................................................. 18

3 Installation.................................................................................................................................... 19

3.1 General Installation Instructions..................................................................................................................... 19

3.2 Retractable Fitting: Installation ....................................................................................................................... 20

3.3 Media Connection / ZU0631: Installation on Strain Relief Bracket..................................................... 20

3.4 Outlet........................................................................................................................................................................ 21

3.4.1 Outlet Hose: Installation Instructions .............................................................................................. 21

3.4.2 Outlet Hose: Installation ....................................................................................................................... 22

3.5 Media Connection................................................................................................................................................ 23

3.5.1 Media Connection: Installation Instructions ................................................................................. 23

3.5.2 Multiplug: Installation ........................................................................................................................... 24

3.5.3 Electro-Pneumatic Controller: Connection.................................................................................... 24

3.5.4 ZU0631 Standard Media Connection: Installation...................................................................... 24

3.6 Sensor Cable: Installation .................................................................................................................................. 25

4 Commissioning............................................................................................................................. 26