Page 4 of 12 0901225 Rev: X6 (draft 10/09/20)

PRE-RELEASE COPY -- NOT FOR DISTRIBUTION

INTRODUCTION

Electrostatic spraying is a preferred method of application as the solution wraps around objects to surfaces out of the

direct line of spray. This assures better coverage even to uneven surfaces. Also, due to the droplets having the same

charge, the droplets repel each other rather than clumping together as they exit the spray nozzle. This assures an

even coating across surfaces to maximize coverage and contact.

Knight’s Stratus ProTM is a rapid coverage spray system offering electrostatic spray as a feature that can be enabled

or disabled to comply with the requirements of the product you are using. The Stratus ProTM produces a spray mist

that evenly coats surfaces at a rapid pace allowing for quick, easy coverage of large surface areas.

APPLICATIONS

Healthcare: Bedrails, door handles, hallway railings, walkers, bathroom surfaces, chair surfaces, etc.

Schools: Desktops, chairs, door handles, lockers, restroom surfaces, water fountains, cafeteria tables, etc.

Fitness Centers: All equipment, doors, desk, restrooms, etc.

Airports: Chairs, scanners, desks, kiosks, restrooms, escalators/elevators etc.

Hotels: Door handles, lobby area, breakfast area, tables, remote controls, chairs, curtains, bathrooms, etc.

Veterinary Practice / Kennels: Cages, kennels, stables, crates, tables, etc.

SPECIFICATIONS

• Flow Rate: 4.0 oz/min (+/- 0.2 oz).

• Spray Distance: 3 – 5 feet (apex of cone).

• Spray Width: 1 – 2 feet.

• Droplet Size: 43.4 to 57.3 microns VMD (depending on distance from spray nozzle).

• Sprayer features electrostatic electrode at end of nozzle giving spray solution an electrical charge which will

encourage the spray to wrap around objects out of the direct spray path for better coverage.

• Operating Air Pressure: 24 psi (+/- 3 psi).

• Available Spray Time: 90minutes (full tank).

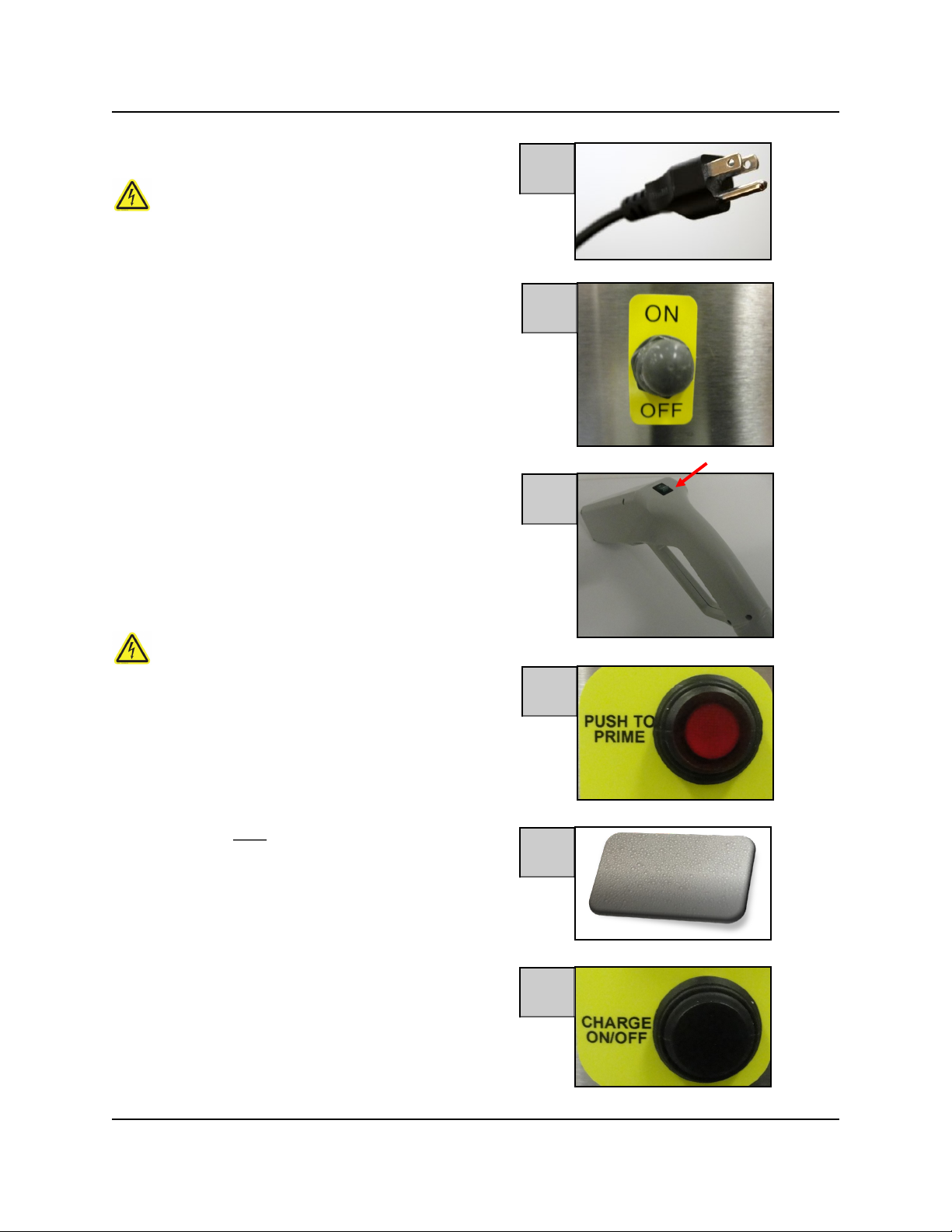

• Hose: 10 feet. A reinforced outer hose containing within a separate air hose, electrical wires required for

electrostatic module and a chemical supply line running together (possibly wrapped together) to the sprayer.

• Electrical: 115 VAC (USA applications), 50 foot cord.

• Circuit breaker at back of unit for electrical feed (15A).

• Switch to disengage electrostatic feature yet allow sprayer to work otherwise.

• For indoor commercial use only.

• (Pending) The Knight Stratus ProTM meets Underwriters Laboratories published and nationally recognized

standards for safety.

REQUIREMENTS

• 115 VAC main power source.

• Chemical requirement: The Stratus ProTM is designed to use diluted chemical. The use of a proportioner is

recommended for easy, accurate dilution of concentrates. Follow all use directions and precautions on the product

label and SDS.