-1-

IN-WALL TANK

INSTALLATION INSTRUCTIONS

K-6283T/K-6284T/K-6285T

100 HYDRO-TOWER 100

ODEON

·

·

·

·

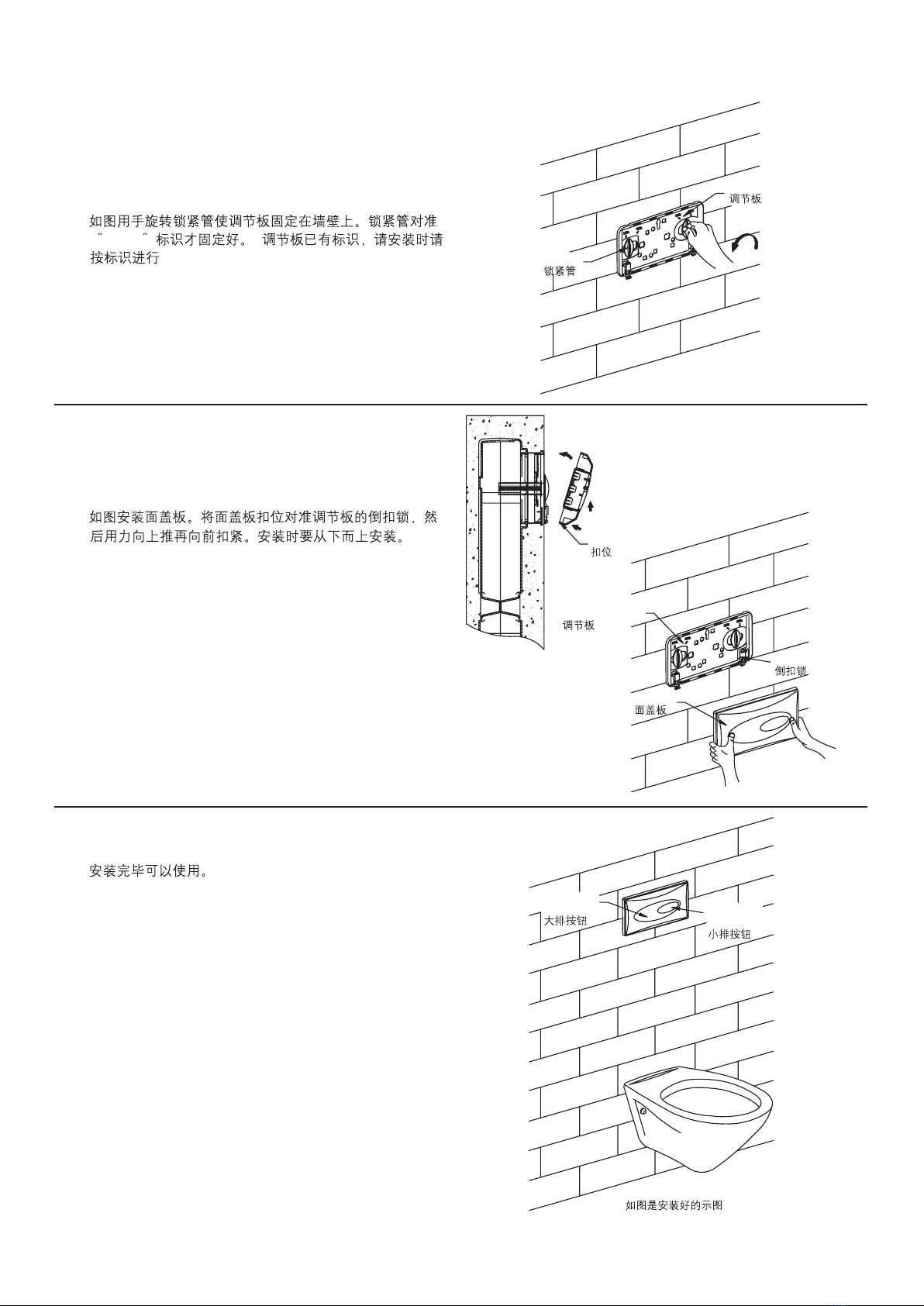

Read installation guide in illustration and word file

carefully, and install the tank according to instructions in

the guide to avoid product damage and installation

inconvenience caused by inappropriate operation.

All data contained is based upon the last product

information available at the time of publication. Kohler

Company reserves the right to implement changes of

product characteristics, packaging and availability at any

time without further notice.

Do not apply erosive cleanser and solvent in the tank,

which will damage tank spares and result in leakage in the

tank. Kohler will not be responsible for any damage

related to above mentioned cleanser or solvent.

Do not apply spares that are not provided by Kohler, and

please note that glass adhesive tape shall not be applied

to the installation of Kohler spares. Kohler will not be

responsible for any damage related to installation with

spares not provided by Kohler.

·Water temperature must not exceed 27 C.

o

·

·

·

·

·27oC

.......................................................K-6283T

100 ( ) .....................K-6284T

( )........................K-6285T

Ordering Information

RATIO In-Wall Tank Faceplate...................................K-6283T

HYDRO-TOWER 100 In-Wall Tank(With Frame) .......K-6284T

ODEON In-Wall Tank(Without Iron Rack) ..................K-6285T

·

·

·

·

·

(K-6284T) 3/6L

(K-6285T) 7.7 0.2L

/

Function Explanation

·

·

·

·

·

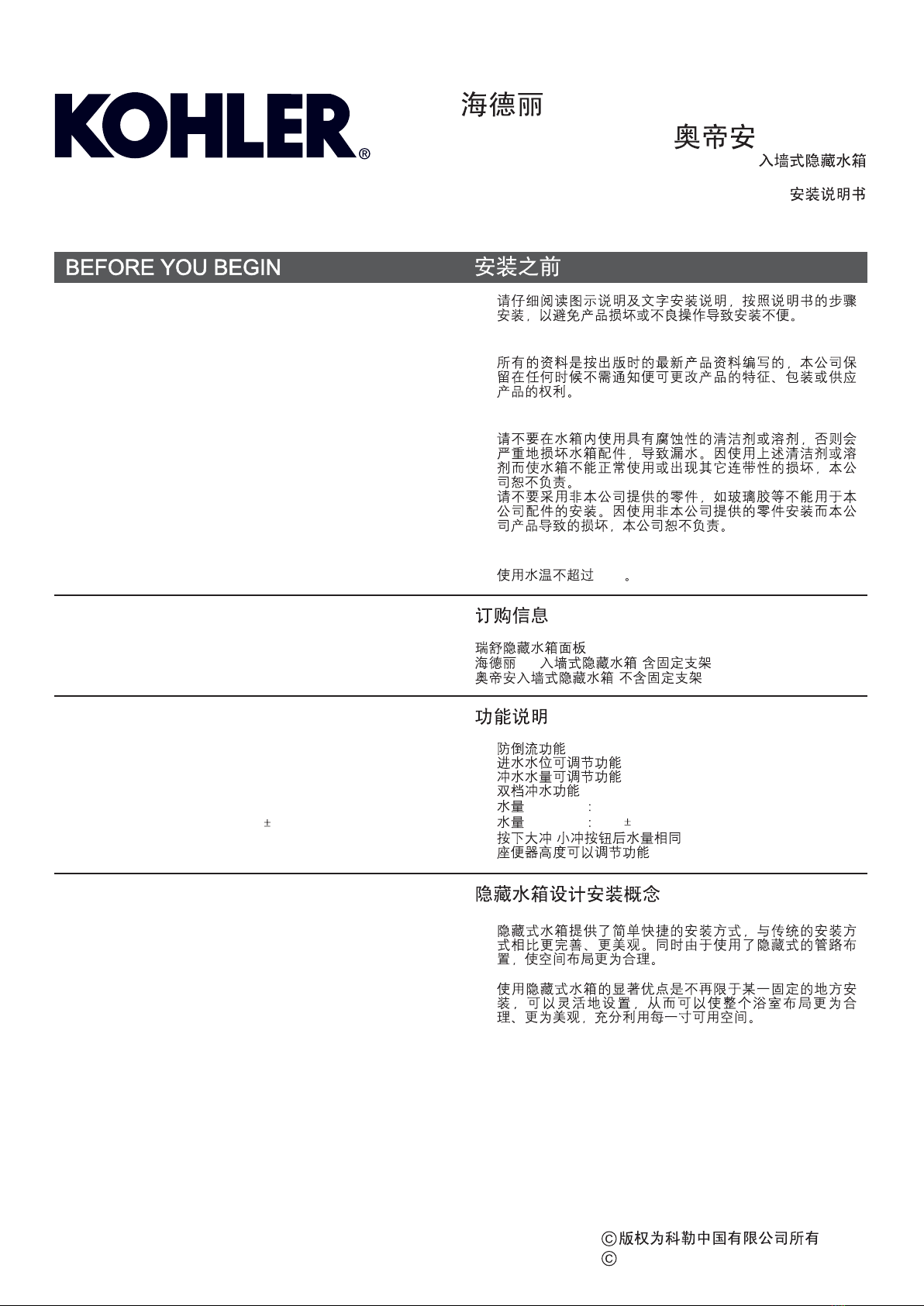

Anti flow-backwards

Adjustment of inlet water level

Adjustment of flushing volume

Single/double gear

Adjustable toilet height

flushing

Water usage (K-6284T): 3/6L

Water usage (K-6285T): 7.7 0.2L

Same water usage for both small/big push buttons

·

·

·

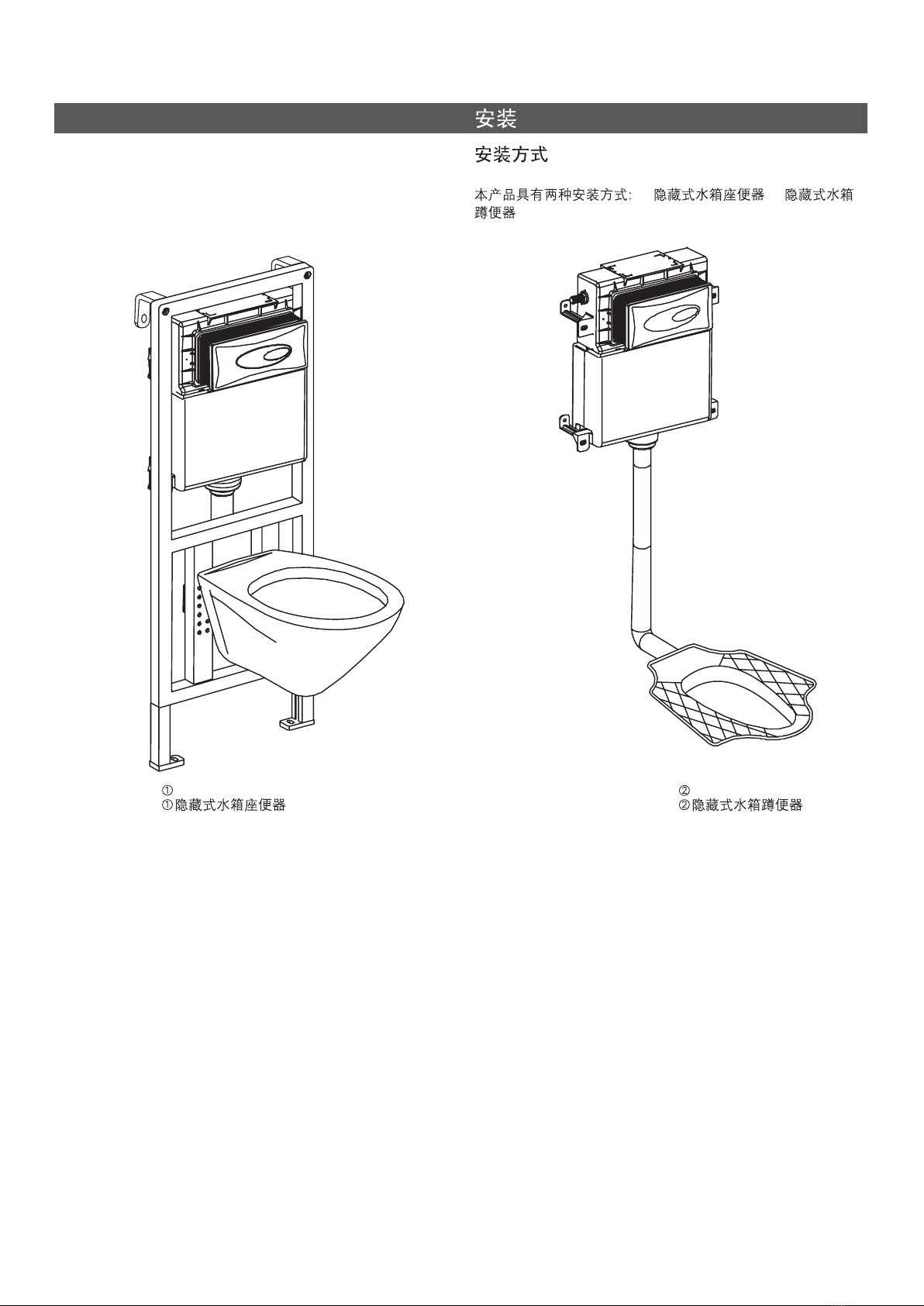

·

Installation of in-wall tank is much easier and nice-looking

comparative to that of traditional tank. Meanwhile, the

space layout will be more reasonable due to the

application of in-wall tank pipes and connectors.

The most remarkable advantage of in-wall tank is that the

installation will never be limited to certain area, and can

be installed wherever as you wish, which will make the

bathroom layout more reasonable and nice-looking, and

make good use of every inch of the bathroom space.

Design And Installation Concept Of In-wall Tank

, 2012

Copyright Kohler China Ltd., 2012

1048671-T01-K