-6-

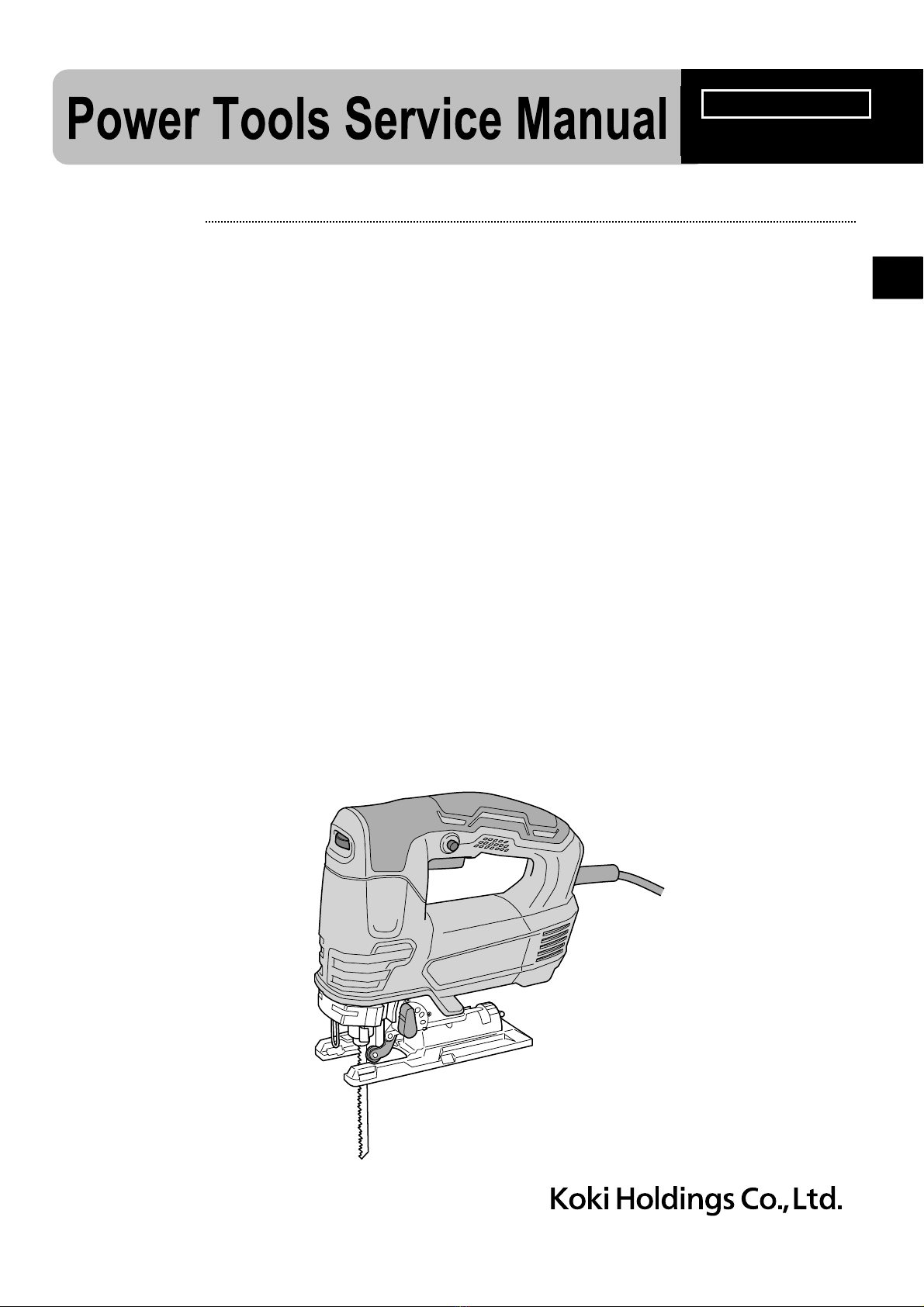

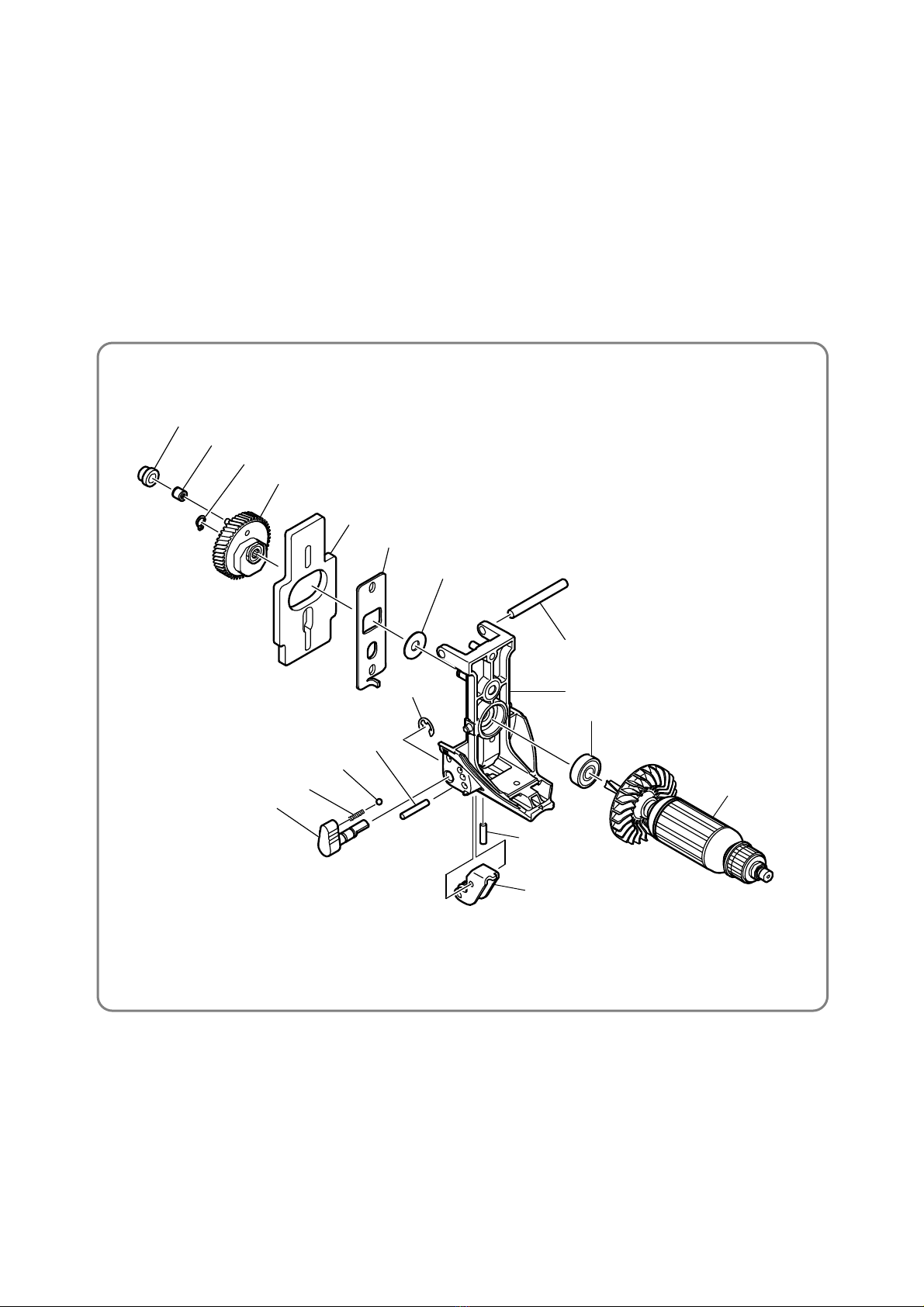

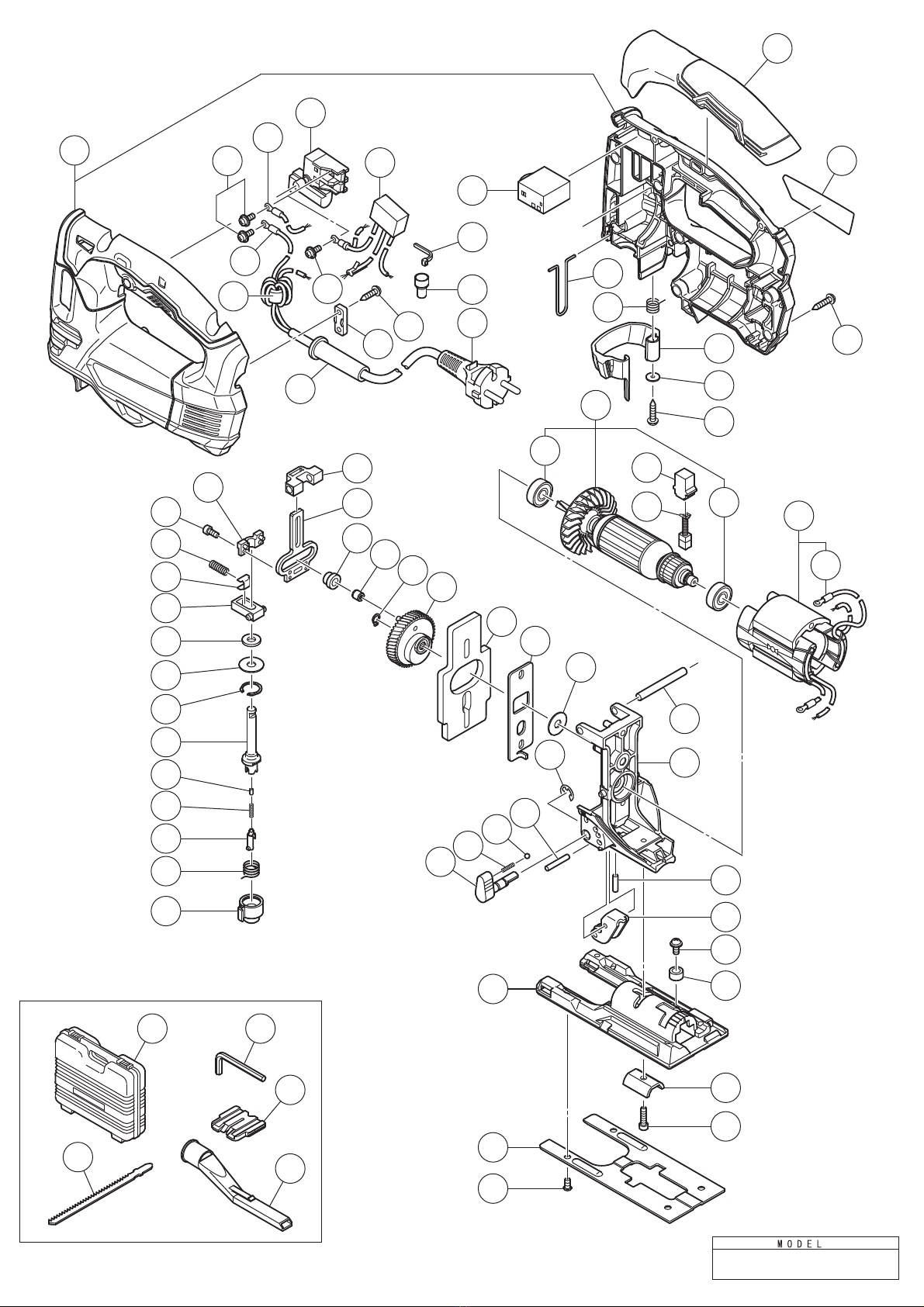

3. Reassembly of housing (A).(B) set, gear holder, and plunger ass’y

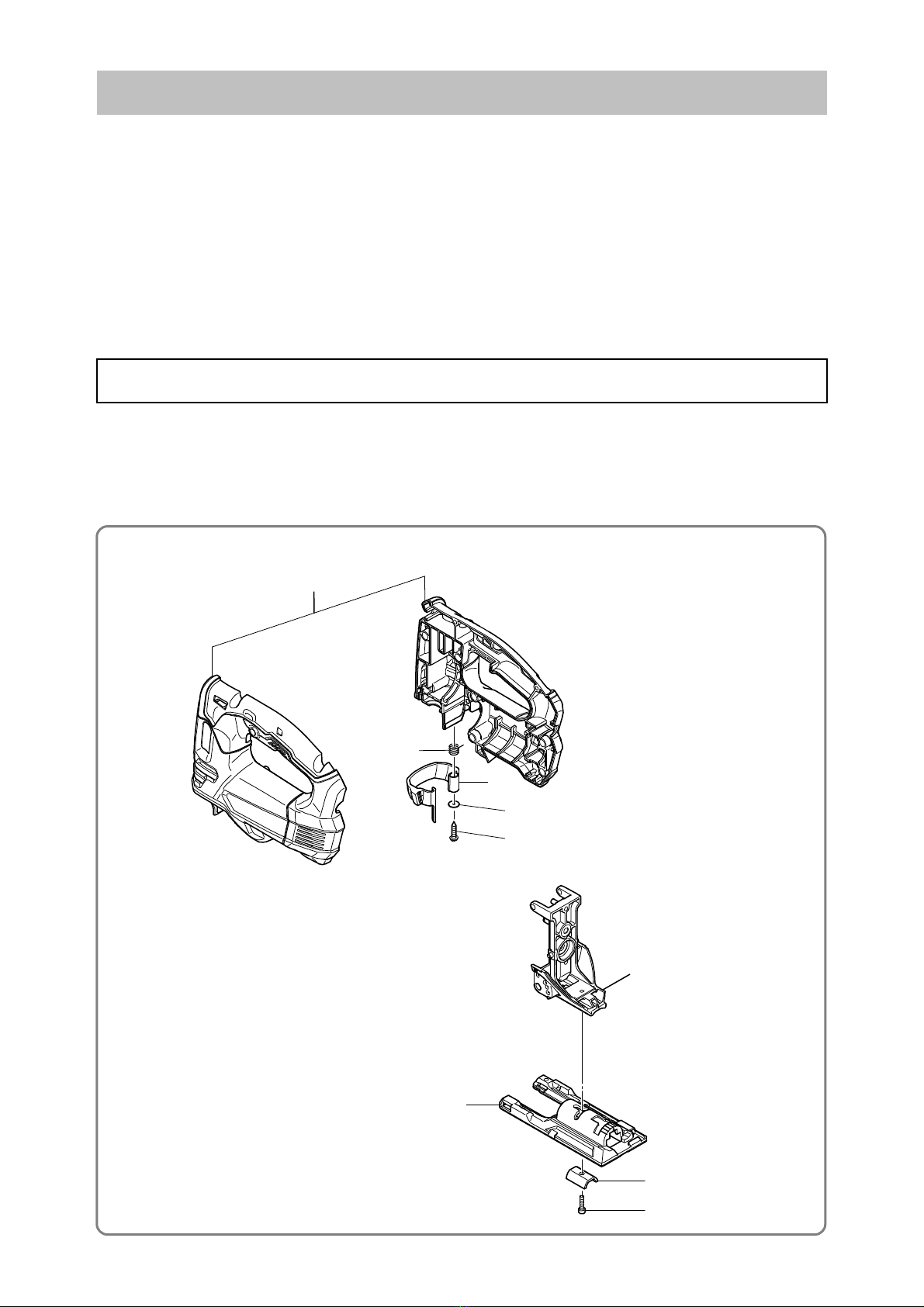

(1) Mount the parts from Armature Ass’y [23] through the plunger ass’y to the Gear Holder Ass’y [59]. Insert

the Armature Ass’y [23] into the Stator Ass’y [27]. At this time, face the shear droop side of the Balance

Weight [49] to the Orbital Cam [50]. Mount the new Retaining Ring for D7 Shaft [47] facing its shear

droop side to the Gear [48]. At this time, check that the Retaining Ring for D7 Shaft [47] is properly fitted

in the spindle groove.

NOTE: • Do not reuse the Retaining Ring for D7 Shaft [47].

• Be careful not to open the Retaining Ring for D7 Shaft [47] excessively when mounting.

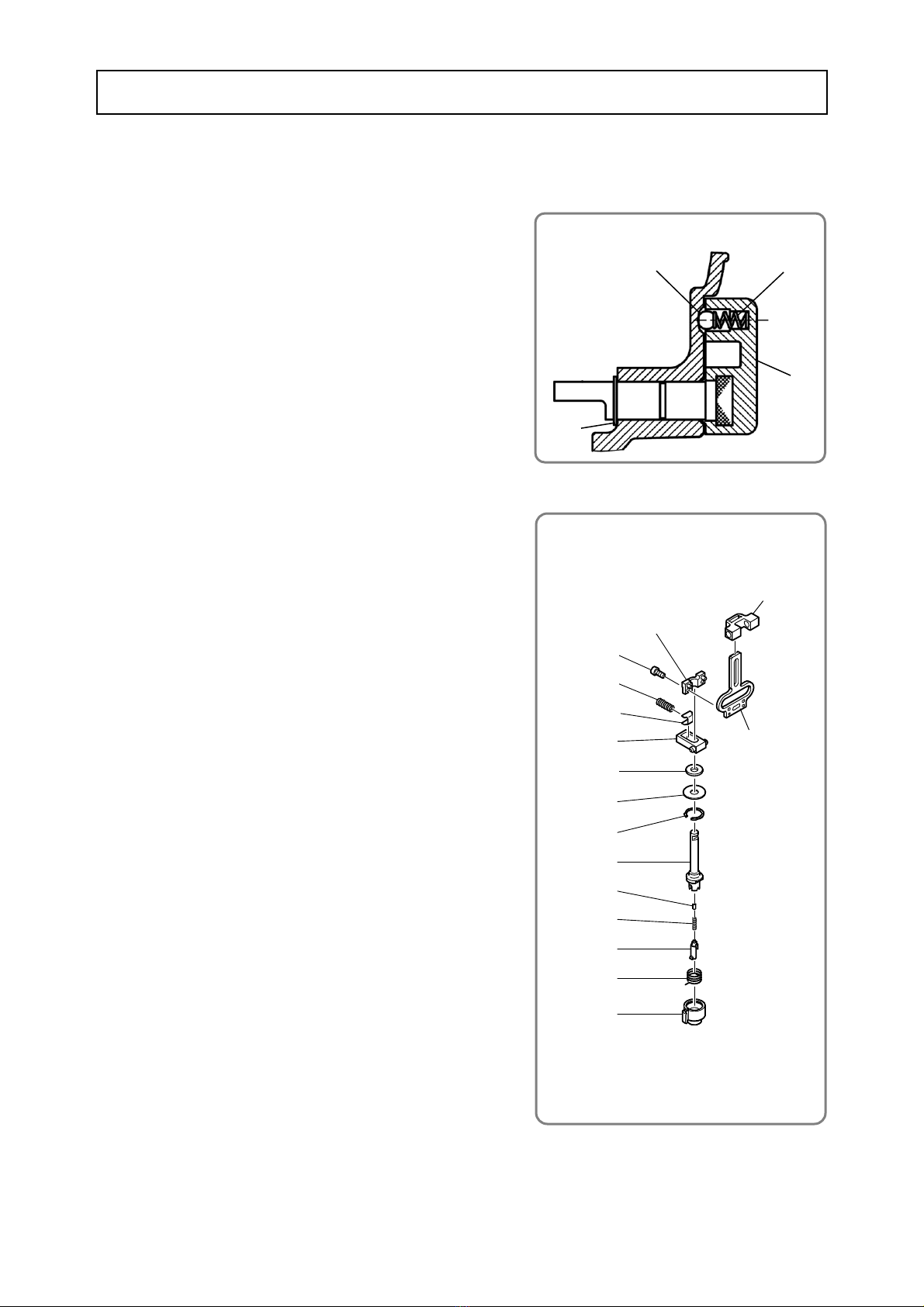

(2) Fit the protrusions of Plunger Holder (B) [33] in the holes of Housing (A).(B) Set [1]. At this time, check

that Washer (A) [35] and Packing [34] are mounted between Housing (A).(B) Set [1] and Plunger Holder

(B) [33].

(3) Fit the protrusions of the Gear Holder Ass’y [59] in the holes of Housing (A).(B) Set [1].

(4) Fit the D6 Pin [58] in the holes of Housing (A).(B) Set [1] to fix the mechanical unit to Housing (A).(B)

Set [1].

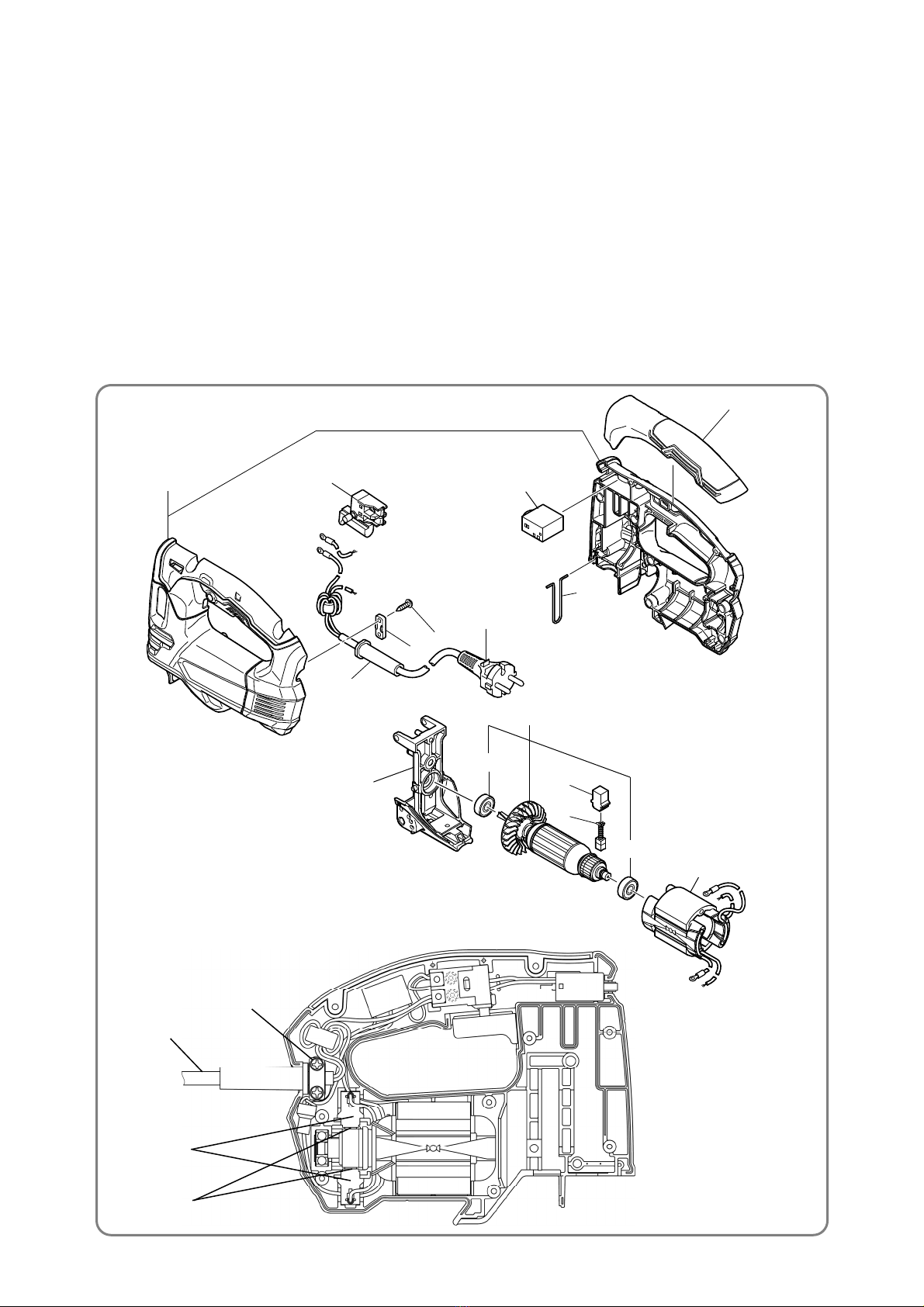

Apply specified amount of grease to the following portions.

Nippeco SEP-3A grease

• Entire circumference of the Gear [48], particularly its teeth

• Both sides of Washer (A) [35]

• Both sides of the Orbital Cam [50]

• Both sides of the Balance Weight [49]

• Outer circumference of Connecting Piece (A) [45]

• Tooth flank of the Armature Ass’y [23]

• Outer circumference of the Steel Ball 5/32 [53]

• Entire circumference of Plunger (A) [44]

• Sliding portion of the Roller Holder [61] and the Needle Roller D4 x 24 [52]

Molub-Alloy No. 777-1 grease

• Inner diameter portion of the gear ass’y (needle bearing: 1.0 g)

• Inner circumferences of Connecting Piece (A) [45] and Needle Bearing [46] (0.5 g)

• Holes of the Orbital Cam [50]

• Holes of the Balance Weight [49]

• Sliding portion of the gear ass’y and the Balance Weight [49]

Nippeco BC-4 grease

• Cylindrical portion (7 mm in dia.) of Plunger (B) [37] (1.0 g)

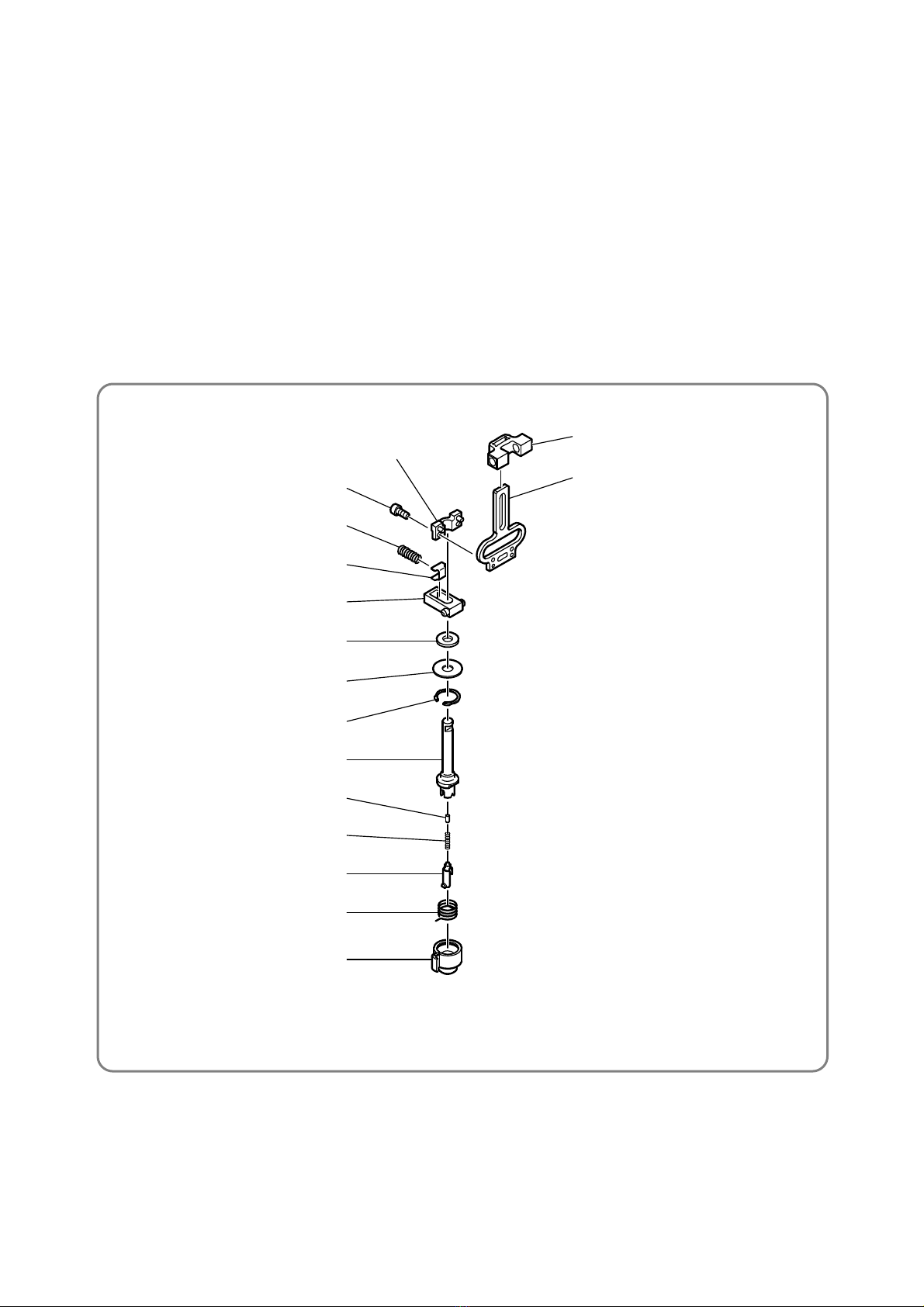

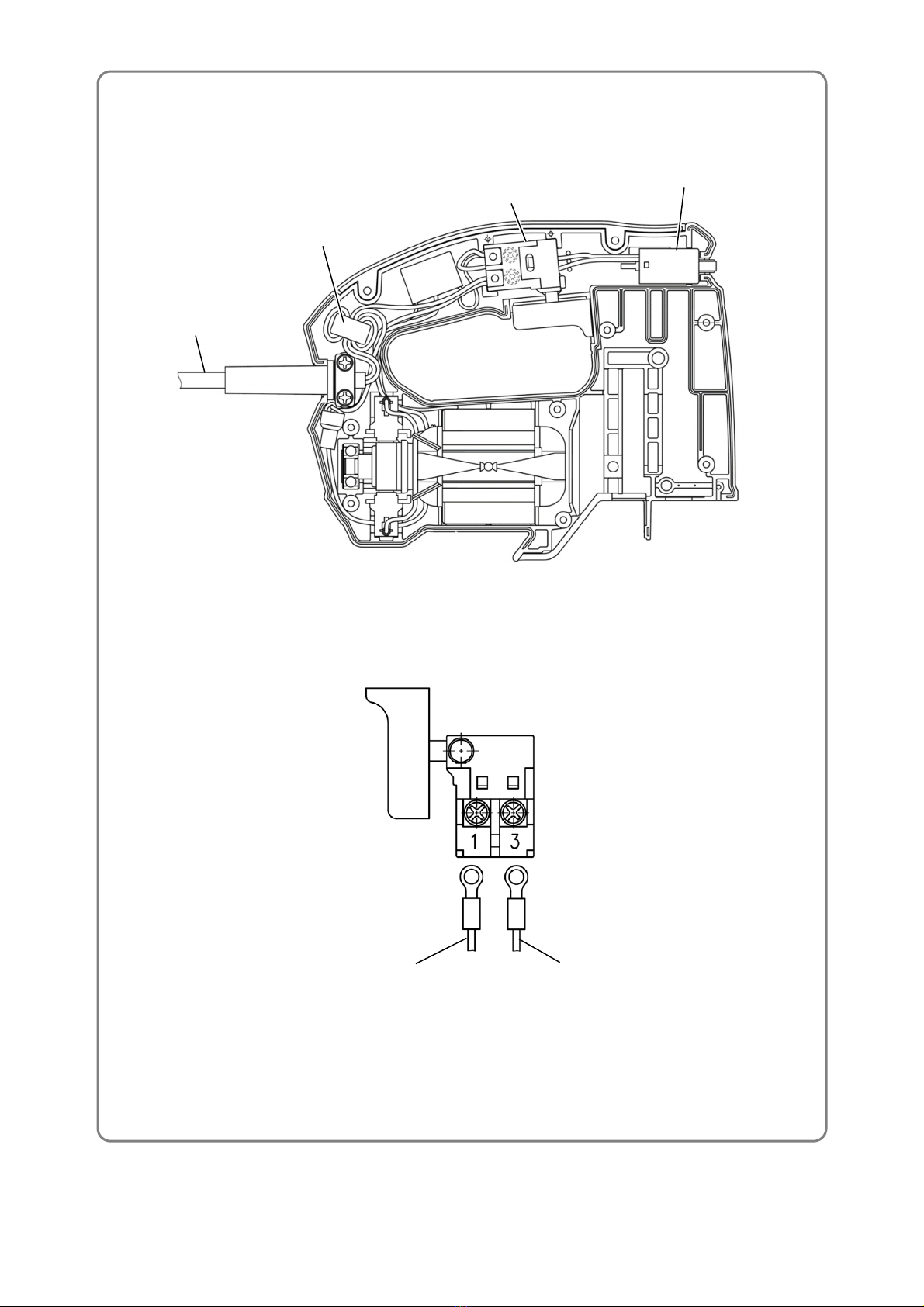

• Tapping Screw (W/Flange) D4 [10][17] --------------------------------------- 1.96±0.49 N•m (20±5 kgf•cm)

• Tapping Screw (W/Flange) D3 x 20 [22] -------------------------------------- 0.88± 0.1 N•m (9±1 kgf•cm)

• Seal Lock Hex. Socket Hd. Bolt M3 x 6 [30]--------------------------------- 1.47± 0.29 N•m (15±3 kgf•cm)

• Hex. Socket Hd. Bolt M5 x 18 [65] --------------------------------------------- 4.90±0.49 N•m (50±5 kgf•cm)

• Special Bolt [57] -------------------------------------------------------------------- 2.76±0.29 N•m (28±3 kgf•cm)

• Machine Screw (W/Washer) M4 x 5 [62] ------------------------------------- 1.76±0.29 N•m (18±3 kgf•cm)

• Machine Screw (W/Washer) M3.5 x 6 [2] ------------------------------------ 0.6±0.15 N•m (6±1.5 kgf•cm)

Application of lubricant

Tightening torque