English

1

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face

and body.

CAUTION: When not in use, place tool on its side on a stable surface where it will

not cause a tripping or falling hazard. Some tools with large battery packs will stand

upright on the battery pack but may be easily knocked over.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V ..............volts A................amperes

Hz ............hertz W ..............watts

min............minutes ............alternating current

..........direct current no..............no load speed

..............Class II Construction ..............earthing terminal

..............safety alert symbol .../min ........revolutions per minute

Important Safety Instructions for Battery Packs

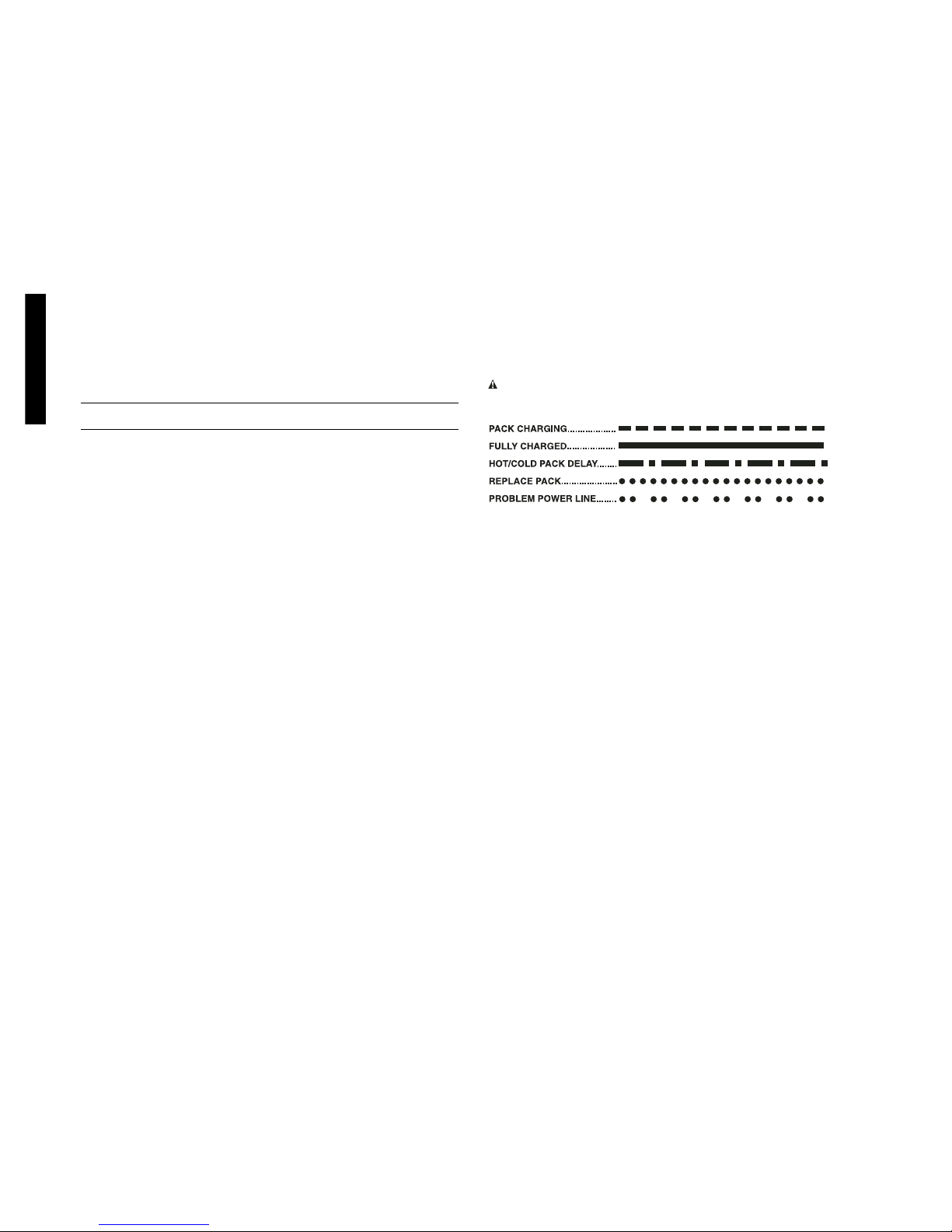

Your tool uses an 18.0 Volt DEWALT battery pack. When ordering replacement battery

packs, be sure to include catalog number and voltage. Extended Run-Time battery packs

deliver more run-time than standard battery packs. Consult the chart at the end of this

manual for compatibility of chargers and battery packs.

NOTE: Your tool will accept either standard or Extended Run Time battery packs.

However, be sure to select proper voltage. Batteries slowly lose their charge when they are

not on the charger, the best place to keep your battery is on the charger at all times.

The battery pack is not fully charged out of the carton. Before using the battery pack and

charger, read the safety instructions below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

•Do not incinerate the battery pack even if it is severely damaged or is completely

worn out. The battery pack can explode in a fire.

•A small leakage of liquid from the battery pack cells may occur under extreme

usage or temperature conditions. This does not indicate a failure. However, if the

outer seal is broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for a minimum of 10

minutes and seek immediate medical attention. (Medical note: The liquid is 25-35%

solution of potassium hydroxide.)

• Charge the battery packs only in D

E

WALT chargers.

•DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations where the temperature

may reach or exceed 105°F (40˚) (such as outside sheds or metal buildings in

summer).

DANGER: Never attempt to open the battery pack for any reason. If battery pack case

is cracked or damaged, do not insert into charger. Electric shock or electrocution may

result. Damaged battery packs should be returned to service center for recycling.

NOTE: Battery storage and carrying caps areprovided for use whenever

the battery is out of the tool or charger. Remove cap before placing battery in

charger or tool.

WARNING: Do not store or carry battery so that metal objects can

contact exposed battery terminals. For example, do not place battery in

aprons, pockets, tool boxes, product kit boxes, drawers, etc., with loose nails,

screws, keys, etc. without battery cap. Transporting batteries can possibly cause fires

if the battery terminals inadvertently come in contact with conductive materials

such as keys, coins, hand tools and the like. The US Department of Transportation

Hazardous Material Regulations (HMR) actually prohibit transporting batteries in

commerce or on airplanes (i.e., packed in suitcases and carry-on luggage) UNLESS they

are properly protected from short circuits. So when transporting individual batteries, make

sure that the battery terminals are protected and well insulated from materials that could

contact them and cause a short circuit.

CAUTION: Battery pack must be securely attached to tool. If battery pack is detached,

personal injury may result.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corporation) Seal on the

nickel-cadmium battery (or battery pack) indicates that the costs to recycle

the battery (or battery pack) at the end of its useful life have already been

paid by DEWALT. In some areas, it is illegal to place spent nickel-cadmium

batteries in the trash or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

RBRC™ in cooperation with DEWALT and other battery users, has established programs

in the United States to facilitate the collection of spent nickel-cadmium batteries. Help

protect our environment and conserve natural resources by returning the spent nickel-

cadmium battery to an authorized DEWALT service center or to your local retailer for

recycling. You may also contact your local recycling center for information on where to drop

off the spent battery.

RBRC™ is a registered trademark of the

Rechargeable Battery Recycling Corporation.

Important Safety Instructions for Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions for

battery chargers.

• Before using charger, read all instructions and cautionary markings on charger, battery

pack, and product using battery pack.

DANGER: 120 volts are present at charging terminals. Do not probe with conductive

objects. Electric shock or electrocution may result.

WARNING: Do not allow any liquid to get inside charger. Electric shock may result.

CAUTION: To reduce the risk of injury, charge only D

E

WALT nickel cadmium recharge-

able batteries. Other types of batteries may burst causing personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in to the power supply,

the exposed charging contacts inside the charger can be shorted by foreign material.

Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean.

•DO NOT attempt to charge the battery pack with any chargers other than the

ones in this manual. The charger and battery pack are specifically designed to work

together.

•These chargers are not intended for any uses other than charging D

E

WALT

rechargeable batteries. Any other uses may result in risk of fire, electric shock or

electrocution.

•Do not expose charger to rain or snow.

•Pull by plug rather than cord when disconnecting charger. This will reduce risk of

damage to electric plug and cord.

•Make sure that cord is located so that it will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

•Do not use an extension cord unless it is absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution.