KOLDTECH

The Technology of Excellence

OASMs-616-C-19-07-05/13/1/07 4 OF 18

ability of the cabinet to maintain internal temperature. Should ambient temperature exceed 36oC

we cannot guarantee the maintenance of internal temperature to required standards.

2.4

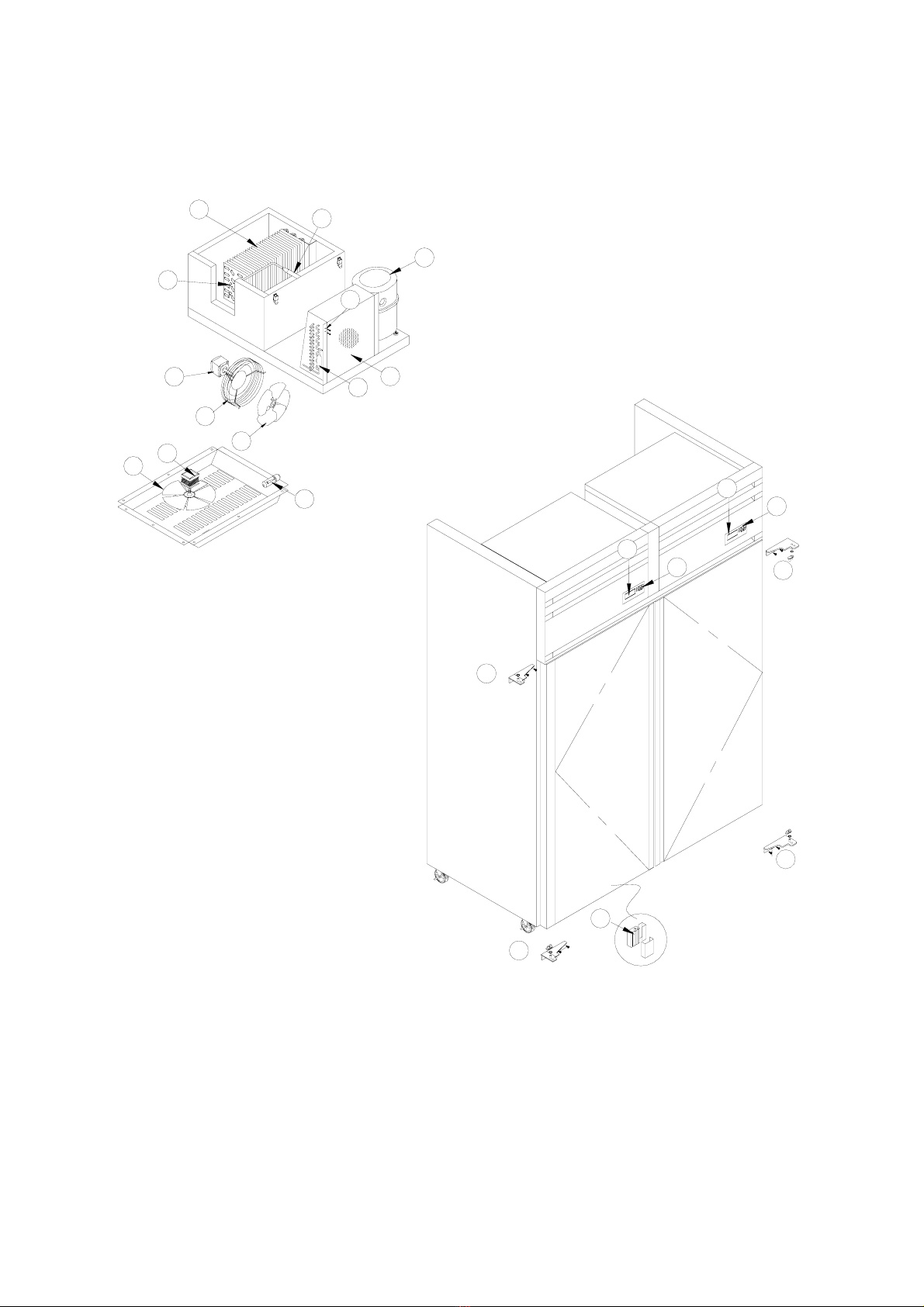

2.3.2 The unit should be set on a level and firm surface.

Draining: Special models may require drain pipe for condensate water, End-user should well

explore from specification sheet before plugging in and self prepare of drain pipe as appropriate.

2.5 Ventilation: ventilating grills or louvers must not be obstructed for proper operation.

2.6 Electrical Work Preparation:

2.6.1 For safety reasons, the unit must be properly earthed. Check and make sure that the outlet is

properly grounded. If a grounded plug is not available, a separate earth ground must be installed to

prevent any electrical hazard. A properly rated circuit breaker should be installed to the supply

outlet. Check for proper supply voltage before plugging in the unit. Please refer to voltage

requirements on the nameplate of the unit.

2.6.2 Plug the unit into the wall outlet. Turn the unit on using the on/off switch.

2.7 Starting: After turning on the unit for the first time, if there is any unusual odour, heat, smoke or

vibration immediately turn off and unplug the unit and call for a service technician. The unit

should be closely monitored during the first hour of operation.

2.8 Product Loading: The thermostat is set at the factory for optimum operating temperature. Time

taken to attain the operating temperature depends on the temperature of the food being loaded, the

frequency of the door opening, ambient temperature etc. The unit should reach operating

temperature during the first 4-6 hours for chiller and 8-12 hours for freezer of operation.

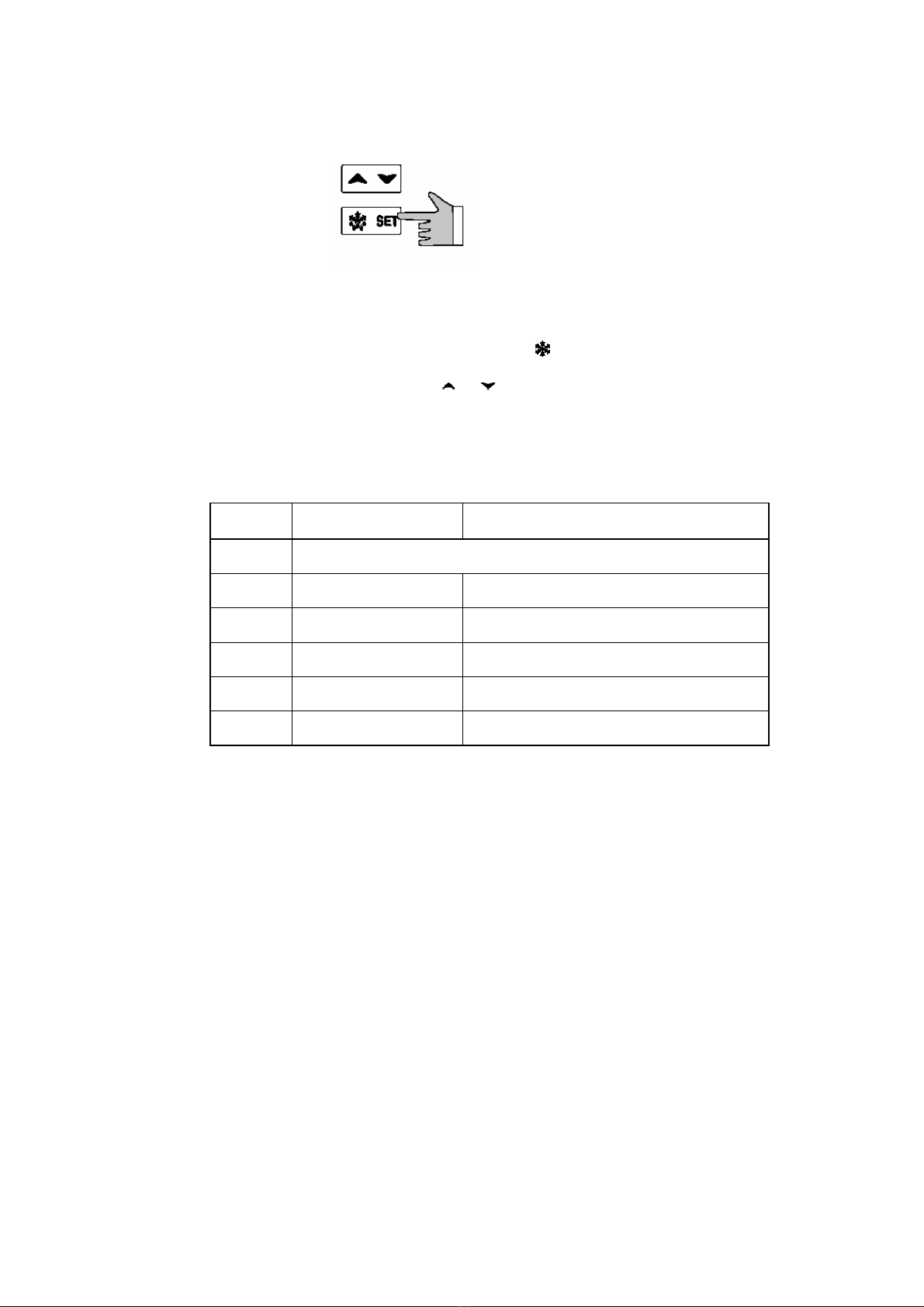

2.9 Machine Performance: To prevent compressor damage, the unit is equipped with a Time Delay

Circuit, which shall activate the compressor within 2 minutes after turning on the power or after

restarting.

2.10 Defrosting: Defrosting the circuit is set from the factory for optimum operation. Do not attempt to

alter the setting.

PLS NOTE do not disassemble the unit. Any service performed by parties other than our

authorized may void the warranty.

3. PRODUCT CLEANING

3.1 CLEANING Stainless Steel surface, P.V.C. and Display Glass: Users can wash by lukewarm

soapy water (or recommended cleaner) and, later, thoroughly rinses or wiping all surfaces with

water or moistened clothes respectively. Finally, polish with dry soft cloth.