www.kolpak.com 800-225-9916 2

Table of Contents

General Safety Information .............................................................................................3

Receiving Inspection.......................................................................................................4

Panel Count ....................................................................................................................4

Panel Storage ..............................................................................................................4-5

Panel Identification..........................................................................................................5

Site Preparation ...........................................................................................................6-7

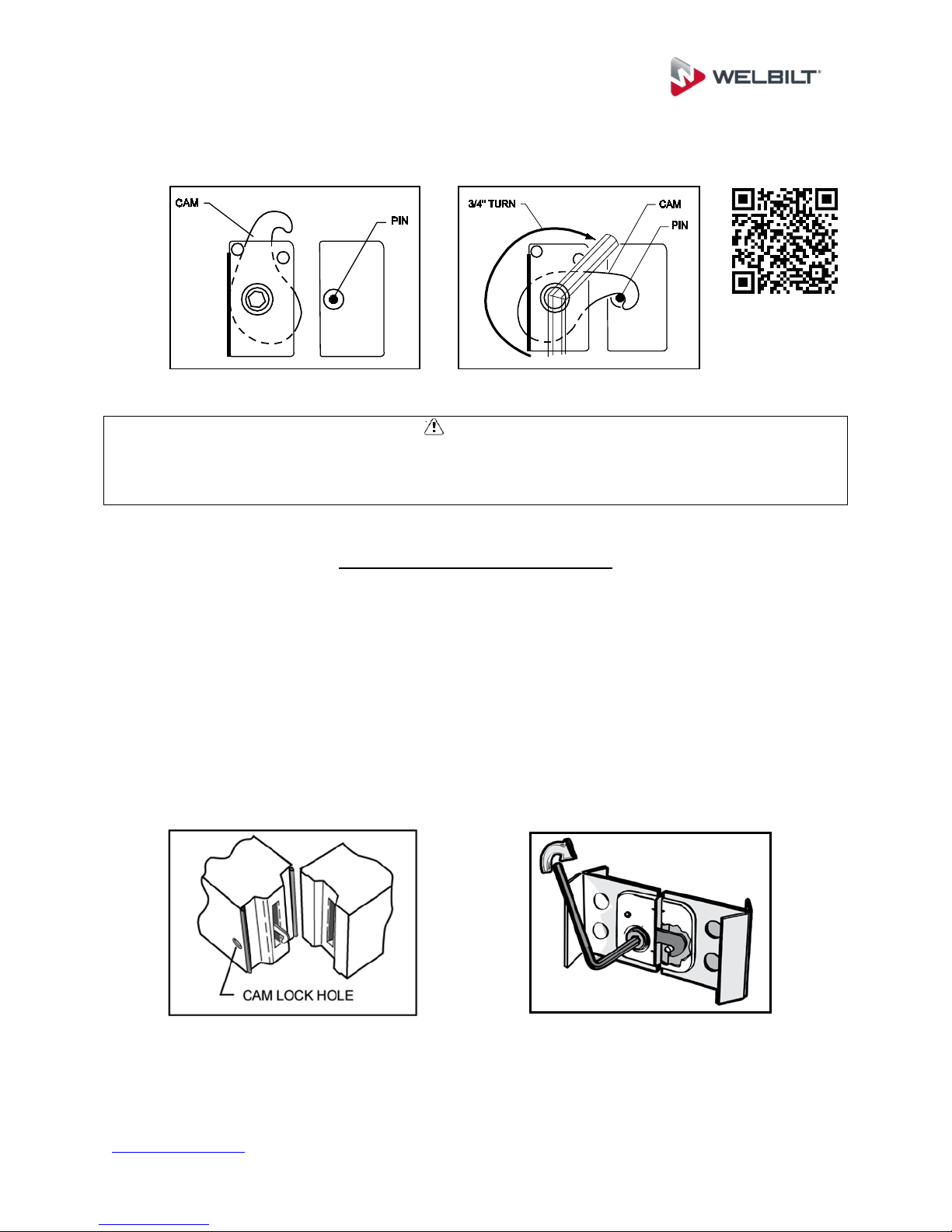

Cam Action Panel Fasteners........................................................................................7-8

General Installation Guidelines .......................................................................................8

Screed Identification & Installation.............................................................................9-11

Floor Panel Installation.............................................................................................12-13

Floor Overlay Installation...............................................................................................14

Concrete & Tile Flooring................................................................................................ 15

Wall Panel & Door Section Installation.....................................................................15-16

Ceiling Panel Installation...............................................................................................16

Split-Over Partition Wall/Ceiling .................................................................................... 17

Ceiling Support.............................................................................................................. 18

Interior/Exterior Ramps ................................................................................................. 19

Plug Buttons & Penetrations .........................................................................................20

Trim & Wainscoting Material .........................................................................................21

Threshold Installation....................................................................................................22

Door Sweep Adjustment................................................................................................23

Adjustable Hinges......................................................................................................... 24

Thermometer Testing & Recalibration........................................................................... 25

Electrical Connections................................................................................................... 26

Tapered Roof System ...................................................................................................27

Membrane Roof System...........................................................................................28-31

Maintenance & Housekeeping ......................................................................................32

System Start-up Checklist........................................................................................33-36

Warranty Information..................................................................................................... 37